高效率的负载和控制释放的盐酸阿霉素对氧化石墨烯

High-Ef?ciency Loading and Controlled Release of Doxorubicin Hydrochloride on Graphene Oxide

Xiaoying Yang,*,?Xiaoyan Zhang,?Zunfeng Liu,?Yanfeng Ma,?Yi Huang,?and Yongsheng Chen*,?

School of Pharmaceutical Sciences,Tianjin Medical Uni V ersity,Tianjin 300070,China,Center for Nanoscale Science and Technology and Key Laboratory of Functional Polymer Materials,Institute of Polymer Chemistry,College of Chemistry,Nankai Uni V ersity,Tianjin 300071,China

Recei V ed:July 30,2008;Re V ised Manuscript Recei V ed:September 10,2008

A novel graphene oxide -doxorubicin hydrochloride nanohybrid (GO -DXR)was prepared via a simple noncovalent method,and the loading and release behaviors of DXR on GO were investigated.An ef?cient loading of DXR on GO as high as 2.35mg/mg was obtained at the initial DXR concentration of 0.47mg/mL.The loading and release of DXR on GO showed strong pH dependence,which may be due to the hydrogen-bonding interaction between GO and DXR.The ?uorescent spectrum and electrochemical results indicate that strong π-πstacking interaction exists between them.

1.Introduction

Nanoscaled drug carriers have emerged as a bridge linking nanotechnology and advanced drug delivery,involving nanoscaled materials such as liposomes,1microspheres,2polymeric shells,3nanoparticles,4carbon nanotubes,5and carbon nanohorns.6The medicine is loaded on these nanos-caled materials by many kinds of mechanisms,such as embedding,surface absorption,hydrogen bonding,and other types of interactions,while the loading capacity of the current developed nanoscaled drug carriers toward the drugs is still low,normally less than 100%.Therefore,for ef?cient drug action,improving the loading ef?ciency is critical in drug carrier research.Recently,Dai et al.7described the ultrahigh loading capacity of highly aromatic molecules toward carbon nanotubes via strong π-stacking interactions.Graphene,as a very recent rising star in material science with two-dimensional structure consisting of sp 2-hybridized carbon,like carbon nanotubes,exhibits remarkable electronic and mechanical properties.8,9Its one-atom thickness and large two-dimensional plane provide it large speci?c surface area.However,little has been done to explore graphene in biological systems.Dai et al.10,11reported PEG-ylated nan-ographene oxide for delivery of water-insoluble cancer drugs and found that the functionalized nanographene sheets are biocompatible without obvious toxicity and can be loaded with aromatic anticancer drug with high ef?ciency.While carbon nanotubes and nanohorns load drugs mainly via surface and tips and form serious bundles when used as drug carrier materials,the graphene sheet is expected to load drugs via its two faces and edges.After oxidation,the graphene can be introduced with hydrophilic groups such as hydroxyl and carboxylic and can be well-dispersed in aqueous solu-tion,12which makes it a promising material as a drug carrier substance.

Herein,we report a novel noncovalent nanohybrid formed by GO with DXR and investigate the in vitro binding and release of DXR by GO.The amount of DXR loaded onto GO is signi?cantly high and dependent on pH value.Furthermore,the interaction between DXR and graphene was investigated by spectroscopy and electrochemistry.2.Experimental Section

Apparatus and Chemicals.Fourier transform infrared spectrometer (FT-IR)(Tensor 27,Bruker),ultraviolet -visible -near IR spectrophotometer (UV -vis -NIR)(JASCO,V-570),atomic force microscope (AFM,Nanoscope IV,Digital Instru-ments,Veeco)and spectro?uorometer (Jobin Yvon,FluoroMax-P)were used to characterize the GO -DXR nanohybrid.Electrochemical experiments were performed with a microcom-puter-based electrochemical analyzer (Lanlike,LK98B).

Graphite was purchased from Qingdao Tianhe Graphite Co.Ltd.,with an average particle diameter of 4μm (99.95%purity).Doxorubicin hydrochloride (DXR)was purchased from Beijing Huafeng United Technology Co.Ltd.a dialysis chamber for the drug release was purchased from Beijing Dingguo Biotech-nology Co.(diameter )36mm),which had a molecular weight cutoff of 8000-15000g/mol.

Preparation of Water-Soluble,Individual Graphene Ox-ide.Graphene oxide (GO)was prepared from puri?ed natural graphite according to a modi?ed Hummer’s method.12

Conjugation of DXR and GO.GO with the ?nal concentra-tion of 0.145mg/mL (determined using a standard GO concentration curve at the absorption of 230nm)was ?rst sonicated with DXR with a certain concentration at a certain pH value for 0.5h and then stirred overnight at room temperature in the dark.All samples were adjusted to pH <6with 1M hydrochloride and then ultracentrifuged at 14000rpm for 1h.

Characterization of GO -DXR.The amount of DXR loaded on GO was determined as follow.The DXR concentration in the upper layer was measured using a standard DXR concentra-tion curve generated using the UV -vis spectrophotometer from a series of DXR solutions with different concentrations.The

*Corresponding authors.Phone:+86(22)2350-0693.Fax:+86(22)2349-9992.E-mail:yangxiaoying@https://www.wendangku.net/doc/127530260.html, (X.Y.),yschen99@https://www.wendangku.net/doc/127530260.html, (Y.C.),

?Tianjin Medical University.?Nankai University.

J.Phys.Chem.C 2008,112,17554–17558

1755410.1021/jp806751k CCC:$40.75 2008American Chemical Society

Published on Web 10/21/2008

DXR concentrations were measured at the wavelength of 233nm.The amount of DXR loaded on GO was determined using eq 1

Φ)(M DXR -M DXR ′)/M GO

(1)

where Φis the amount of DXR loaded on GO,M DXR is the initial amount of DXR,M DXR ′is the amount of DXR in the upper layer,and M GO is the amount of GO added.

The resultant products of GO -DXR were characterized by UV -vis spectrophotometer,FT-IR spectrometer,AFM,and spectro?uorometer.Electrochemical experiments were per-formed with a microcomputer-based electrochemical analyzer.GO,DXR,and GO -DXR were ?rst dispersed in distilled water.The concentrations of DXR and GO in solution of DXR and GO were the same as that in the solution of GO -DXR,respectively.Then 6μL of the solution was cast on a the surface of a glassy carbon (GC)electrode (diameter )4mm).With Ag/AgCl as a reference electrode and platinum electrode as a counter electrode,the electrochemical measurements were carried out in phosphate buffer (50mM,pH 7.4).

Release of DXR from GO -DXR.The nanohybrids GO -DXR (6mg)were dispersed in 3mL of aqueous solution and the dispersion was divided into three equal aliquots.The GO -DXR samples used for the release experiments were placed into the dialysis chambers,which were dialyzed in 60mL of aqueous solution with pH 2,7,and 10,respectively.The drug release was assumed to start as soon as the dialysis chambers were placed into the reservoir.The release reservoir was kept under constant stirring,and at various time points,one of the dialysis chambers was taken out for characterization.The

concentration of DXR released from GO -DXR into distilled water was quanti?ed using UV spectroscopy.3.Results and Discussion

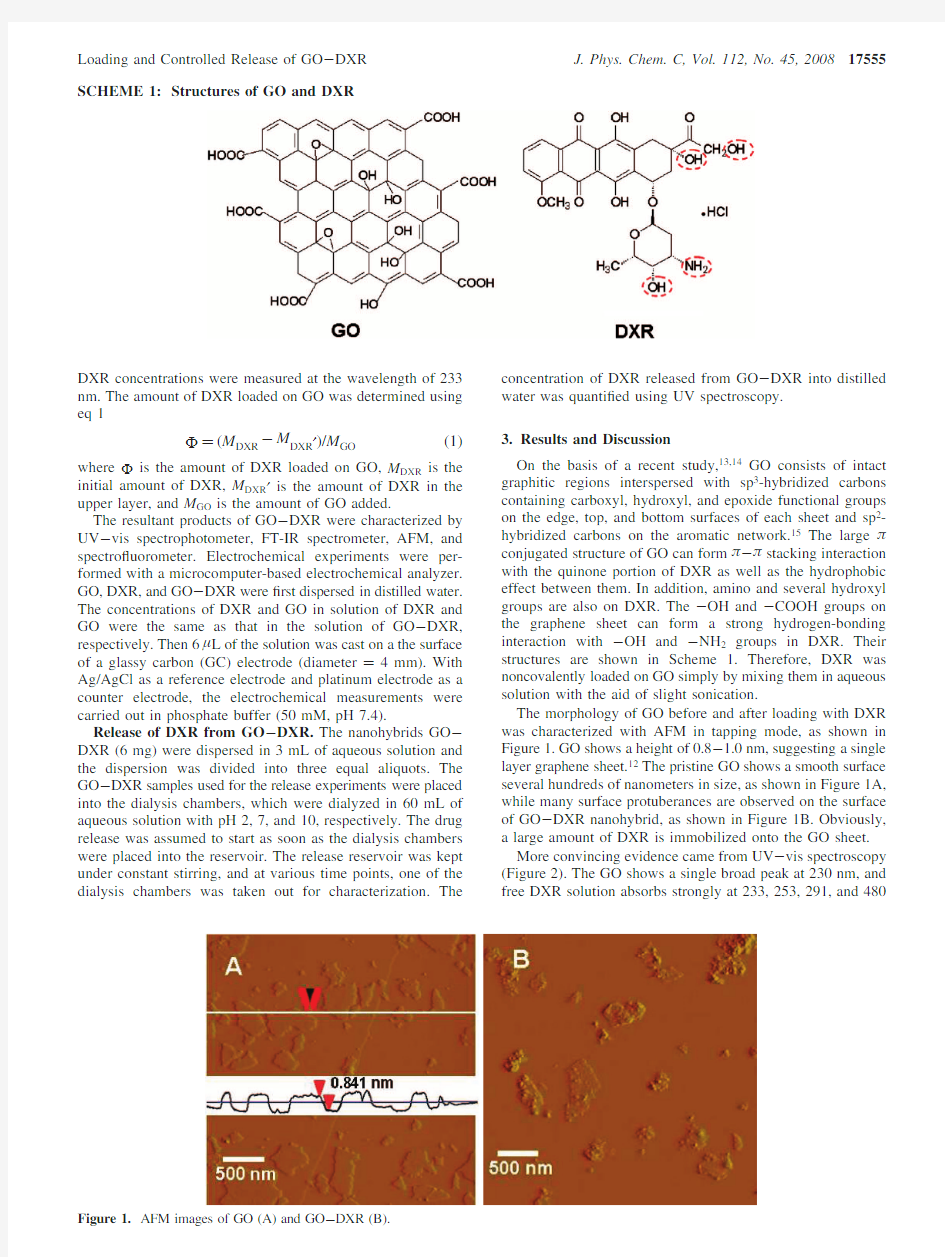

On the basis of a recent study,13,14GO consists of intact graphitic regions interspersed with sp 3-hybridized carbons containing carboxyl,hydroxyl,and epoxide functional groups on the edge,top,and bottom surfaces of each sheet and sp 2-hybridized carbons on the aromatic network.15The large πconjugated structure of GO can form π-πstacking interaction with the quinone portion of DXR as well as the hydrophobic effect between them.In addition,amino and several hydroxyl groups are also on DXR.The -OH and -COOH groups on the graphene sheet can form a strong hydrogen-bonding interaction with -OH and -NH 2groups in DXR.Their structures are shown in Scheme 1.Therefore,DXR was noncovalently loaded on GO simply by mixing them in aqueous solution with the aid of slight sonication.

The morphology of GO before and after loading with DXR was characterized with AFM in tapping mode,as shown in Figure 1.GO shows a height of 0.8-1.0nm,suggesting a single layer graphene sheet.12The pristine GO shows a smooth surface several hundreds of nanometers in size,as shown in Figure 1A,while many surface protuberances are observed on the surface of GO -DXR nanohybrid,as shown in Figure 1B.Obviously,a large amount of DXR is immobilized onto the GO sheet.More convincing evidence came from UV -vis spectroscopy (Figure 2).The GO shows a single broad peak at 230nm,and free DXR solution absorbs strongly at 233,253,291,and 480

SCHEME 1:Structures of GO and

DXR

Figure 1.AFM images of GO (A)and GO -DXR (B).

Loading and Controlled Release of GO -DXR J.Phys.Chem.C,Vol.112,No.45,200817555

nm.The stacking of DXR onto GO was evident from the spectrum of the GO -DXR nanohybrid solution,which shows the characteristic absorption peaks of DXR clearly.Moreover,after forming the nanohybrid,the absorption peaks of DXR show red-shifts.For example,the peaks of DXR at 233and 480nm shifted to 236and 487nm after hybridized with GO,which are generally believed due to the ground-state electron donor -acceptor interaction between the two components,16,17namely GO and DXR in this study.

The FTIR spectra of GO,DXR,and GO -DXR nanohybrid are shown in Figure 3.The peak at 1732cm -1corresponding to ν(C d O)in the spectrum of GO and the C d O peak (1729cm -1)for DXR shift to a lower position at 1716cm -1after forming GO -DXR nanohybrid.This also indicates that DXR be loaded onto GO,and the shift of characteristic peaks may be due to the hydrogen bonding between these two components.A similar result has been observed for the nanohybrid materials formed by ferrocenecarboxylic acid and single-walled carbon nanotubes.18

The loading capacity of DXR on GO was determined by UV spectrum at 233nm,which was calculated by the difference of DXR concentrations between the original DXR solution and the supernatant solution after loading.The loading of DXR on GO was investigated in different initial DXR concentrations with

respect of the same concentration of GO (0.145mg/mL),as shown in Figure 4a.The loading of DXR on GO is 0.55mg/mg at the DXR concentration of 0.09mg/mL.With the increase of the initial DXR concentration,the loading capacity of XDR increases linearly and reaches 2.35mg/mg at the DXR concentration of 0.47mg/mL.Much work is needed to investigate the saturated loading capacity of GO toward DXR,even such a value of loading is far beyond the common drug carrier materials,such as carbon nanohorns 19and polymer vesicles,20which is always below 1mg/mg at saturated carrying concentration.This shows that the graphene is indeed a promising candidate for drug carrier materials.As illustrated in Scheme 1and Table 1,the interaction between GO and DXR may come from π-πstaking between the conjugated structure of graphene sheet and the quinone portion of DXR and the hydrophobic effect between them mainly.Also,the hydrogen bonding between the -OH and -COOH groups of GO and the -OH and -NH 2groups of DXR may exist.Next we investigated the loading behavior of GO toward DXR at different pH conditions,as shown in Figure 4b.

Figure 4b shows the loading of DXR on GO at the initial DXR concentration of 0.174mg/mL at pH values of 2,6,and 10.As expected,the GO shows distinctly different loading capacity toward DXR at different pH values.The loading of DXR on GO is 0.55mg/mg at pH 2,0.91mg/mg at pH 6,and 0.74mg/mg at pH 10.The highest loading capacity is observed at the neutral condition,rather than acidic or basic conditions.The pH-dependent loading may be due to the different degree of hydrogen-bonding interaction between these two species under different pH conditions.Under neutral condition,four kinds of hydrogen bonding can be formed between -COOH of GO and the -OH of DXR,-COOH of GO and the -NH 2of DXR,-OH of GO and the -OH of DXR,and -OH of GO and the -NH 2of DXR (Table 1).Under acidic conditions,-NH 2of DXR forms -NH 3+with H +and therefore cannot participate in hydrogen bonding.In this case,two kinds of hydrogen bonding can occur between -COOH of GO and the -OH of DXR,and -OH of GO and the -OH of DXR.Furthermore,the H +in solution would compete with the hydrogen-bond-forming groups and then weaken the above hydrogen-bonding interaction.Under basic conditions,-COOH of GO exists as -COO -and cannot form a hydrogen bond with -OH or -NH 2groups of DXR.Two kinds of hydrogen bonding interaction can occur between -OH of GO and the -OH of DXR,and -OH of GO and the -NH 2of DXR.Therefore,the strongest hydrogen-bonding interaction between GO and DXR is expected under neutral conditions,and the highest loading of DXR on GO is obtained.The experimental results indicate that the loading capacity of DXR on GO is larger under basic conditions than that under acidic conditions,which may be due to the stronger hydrogen-bonding interaction under basic conditions than that under acid conditions.

In view of the high loading capacity of GO toward DXR,it may be used as a drug carrier candidate material;herein,the release behavior of DXR from GO is shown in Figure 5.The DXR releases slowly from GO and the release rate gradually declines after 5h and about only 11%of the total bound DXR was released from the nanohybrid in the ?rst 30h under neutral conditions (pH 7).As discussed above,the hydrogen-bonding interaction between DXR and GO is the strongest at the neutral condition,resulting in an inef?cient release.The release behavior at basic and acidic conditions indicates that the total releasing amount of DXR in the ?rst 30h for these cases is much higher than at neutral conditions.25%and 71%of the total bound

DXR

Figure 2.UV visible spectra of DXR,GO,and GO -DXR in aqueous

solution.

Figure 3.FTIR spectra of DXR,GO,and GO -DXR.

17556J.Phys.Chem.C,Vol.112,No.45,2008Yang et al.

was released from the nanohybrid after 30h at pH 10and 2,respectively.Such results may be due to the partial dissociation of hydrogen-bonding interaction under acid and basic conditions,as indicated in the above section.The release amount of DXR from the nanohybrid under acid conditions is much higher than that under basic conditions.Similar to the loading behavior,this may be caused by the stronger hydrogen-bonding interaction under basic conditions than that under acid conditions.

For the interaction between the graphene sheet and DXR,π-πstacking may be the most important one because the loading of DXR on GO is still high in the case of decreasing of the hydrogen-bonding interactions under acidic conditions.Therefore,the interaction between GO and DXR in the excited-state using ?uorescence spectroscopy is illustrated in Figure 6.Free DXR exhibits a ?uorescence emission maximum at 593nm with an excited source at 480nm.However,upon excitation at the same wavelength,GO -DXR exhibits signi?cant quench-ing of its emission band.These results imply the presence of a photoinduced electron-transfer process or ef?cient energy transferring along the GO -DXR interface.21,22Similar to the earlier works with daunomycin and single-walled carbon nanotubes,23this ef?cient quenching of ?uorescence emission shows that there is strong π-πstacking interaction between GO and DXR.

Electrochemistry is one of the common tools investigating the electron transfer behavior of nanohybrid of carbon nanotube with electroactive substances.On the basis of the similar chemical structure and physical properties between carbon nanotubes and graphene,cyclic voltametry was used to inves-tigate the electrochemical property of GO -DXR.Figure 7compares the typical cyclic voltammetry curves using the GO -DXR-modi?ed GC electrode and the control electrodes of GO-and DXR-modi?ed GC electrodes,respectively.

The

Figure 4.The loading capacity of DXR on GO in different initial DXR concentrations (a)and at different pH values (b).

TABLE 1:Groups That Can Form Hydrogen Bonds in GO and DXR at Different pH Values

pH value GO DXR 2-OH,-COOH -OH

7-OH,-COOH -OH,-NH 210

-OH

-OH,-NH

2

Figure 5.The release of DXR on GO at different pH

values.

Figure 6.Fluorescence spectra of GO -DXR and DXR in water at the 480nm excitation wavelength.The concentrations of both GO -DXR and DXR were all controlled to be the same according to the loading of DXR on

GO.

Figure 7.Cyclic voltammetry curves of DXR-,GO-,and GO -DXR-modi?ed GC electrodes at a 50mV/s scan rate in phosphate buffer (0.05M,pH 7.4).Both GO and DXR concentrations were controlled to be the same according to the loading of DXR on GO.

Loading and Controlled Release of GO -DXR J.Phys.Chem.C,Vol.112,No.45,200817557

typical redox couple of peaks of DXR with cathode and anode peak potentials at0.319and0.512V were observed,which can be attributed to the characteristic peaks of DXR based on the redox reaction of its quinone portion of the molecule.24 Compared to the redox peak of DXR-modi?ed GC electrode, the redox peak of GO-DXR-modi?ed GC electrode shows signi?cant enhancement at corresponding positions.The en-hanced redox reaction current of GO-DXR modi?ed electrode may be attributed to the synergistic effect due to theπ-πstacking between GO and DXR.The interaction between the two components in the homogeneous nanohybrid is ef?cient in enhancing electron transfer.

4.Conclusions

In this paper,a high loading and pH-dependent release of DXR on GO was investigated.The loading of DXR on GO increased linearly with the increasing of initial DXR concentra-tion as high as2.35mg/mg at the initial DXR concentration of 0.47mg/mL.The pH-dependent loading and releasing may be due to the hydrogen-bonding interactions between GO and DXR. At the same time,the?uorescence spectrum and electrochemical characterization results show that strongπ-πstacking interac-tions exist between GO and DXR.The highly ef?cient loading of DXR on GO and excellent electrochemical and photoinduced electron-transfer activity of GO-DXR nanohybrid could thus offer a way to prepare novel GO-based nanohybrids for applications such as drug carriers and biosensors. Acknowledgment.We gratefully acknowledge the?nancial support from the NSFC(#20644004,#20774047),MoST (#2006CB932702),and NSF of Tianjin City(#07JCYBJC01700, #07JCYBJC03000,#08JCZDJC25300).

References and Notes

(1)Burger,K.N.J.;Staffhorst,R.W.H.M.;de Vijlder,H.C.; Velinova,M.J.;Bomans,P.H.;Frederik,P.M.;de Kruijff,B.Nat.Med. 2002,8,81.

(2)Matsumoto,A.;Matsukawa,Y.;Suzuki,T.;Yoshino,T.;Kobayashi, M.J.Controlled Release1997,48,19.

(3)Maeda,H.;Sawa,T.;Kouno,T.J.Controlled Release2001,74, 47.

(4)Seo,S.B.;Yang,J.;Hyung,W.;Cho,E.J.;Lee,T.I.;Song,Y.J.; Yoon,H.G.;Suh,J.S.;Huh,Y.M.;Haam,S.Nanotechnology2007,18, 475105.

(5)Wu,W.;Wieckowski,S.;Pastorin,G.;Benincasa,M.;Klumpp,

C.;Briand,J.P.;Gennaro,R.;Prato,M.;Bianco,A.Angew.Chem.,Int. Ed.2005,44,6358.

(6)Murakami,T.;Ajima,K.;Miyawaki,J.;Yudasaka,M.;Iijima,S.; Shiba,K.Mol.Pharm.2004,1,399.

(7)Liu,Z.;Sun,X.;Nakayama-Ratchford,N.;Dai,H.ACS Nano2007, 1,50.

(8)Geim,A.K.;Novoselov,K.S.Nat.Mater.2007,6,183.

(9)Zhang,Y.B.;Tan,Y.W.;Stormer,H.L.;Kim,P.Nature2005, 438,201.

(10)Liu,Z.;Robinson,J.T.;Sun,X.;Dai,H.J.Am.Chem.Soc.2008, 130,10876.

(11)Sun,X.;Liu,Z.;Welsher,K.;Robinson,J.T.;Goodwin,A.;Zaric, S.;Dai,H.Nano Res.2008,1,203.

(12)Becerril,H.A.;Mao,J.;Liu,Z.;Stoltenberg,R.M.;Bao,Z.;Chen, Y.ACS Nano2008,2,463.

(13)Lerf,A.;He,H.Y.;Forster,M.;Klinowski,J.J.Phys.Chem.B 1998,102,4477.

(14)Hontoria-Lucas,C.;Lopez-Peinado,A.J.;Lopez-Gonzalez,J.DE

D.;Rojas-Cervantes,M.L.;Martin-Aranda,R.M.Carbon1995,33,1585.

(15)OuYang,F.;Huang,B.;Li,Z.;Xiao,J.;Wang,H.;Xu,H.J.Phys. Chem.C2008,112,12003.

(16)Guldi,D.M.;Marcaccio,M.;Paolucci,D.;Paolucci,F.;Tagma-tarchis,N.;Tasis,D.;Vazquez,E.;Prato,M.Angew.Chem.,Int.Ed.2003, 42,4206.

(17)Murakami,H.;Nomura,T.;Nakashima,N.Chem.Phys.Lett.2003, 378,481.

(18)Yang,X.Y.;Lu,Y.H.;Ma,Y.F.;Li,Y.J.;Du,F.;Chen,Y.S. Chem.Phys.Lett.2006,420,416.

(19)Murakami,T.;Ajima,K.;Miyawaki,J.;Yudasaka,M.;Iijima,S.; Shiba,K.Mol.Pharm.2004,1,399.

(20)Choucair,A.;Soo,P.L.;Eisenberg,https://www.wendangku.net/doc/127530260.html,ngmuir2005,21,9308.

(21)Guo,Z.;Du,F.;Ren,D.M.;Chen,Y.S.;Zheng,J.Y.;Liu,Z.B.; Tian,J.G.J.Mater.Chem.2006,16,3021.

(22)Baskaran,D.;Mays,J.W.;Zhang,X.P.;Bratcher,M.S.J.Am. Chem.Soc.2005,127,6916.

(23)Lu,Y.H.;Yang,X.Y.;Ma,Y.F.;Huang,Y.;Chen,Y.S. Biotechnol.Lett.2008,30,1031.

(24)Komorsky-Lovric,S.Bioelectrochemistry2006,69,82.

JP806751K

17558J.Phys.Chem.C,Vol.112,No.45,2008Yang et al.

氧化石墨烯的结构及应用

氧化石墨烯的结构及应用 2004年,英国曼彻斯特大学物理学家安德烈?海姆(Andre Geim)和康斯坦丁?诺沃肖洛夫(Konstantin Novoselov)成功地从石墨中分离出一层碳原子构成的石墨烯,两人也因“在二维石墨烯材料的开创性实验”,共同获得2010年诺贝尔物理学奖。自此,石墨烯由于其突出的导热性、室温高速载流子迁移率、透光性和力学性能等,同时具有完美的量子隧道效应、半整数的量子霍尔效应、从不消失的电导率等一系列性质,受到了世界各界的广泛关注,也成为科研领域的新兴宠儿。 氧化石墨烯是石墨粉末经化学氧化后的产物,它是一种性能优异的新型碳材料,具有较高的比表面积和表面丰富的官能团。氧化石墨烯复合材料包括聚合物类复合材料以及无机物类复合材料更是具有广泛的应用前景,因为成为研究的又一重点。 一、氧化石墨烯的分子结构 石墨被强氧化剂氧化,氧原子进入到石墨层间,结合л电子,使层面内的二键断裂,并以C=O,C-OH, -COOH等官能团与密实的碳网面中的碳原子结合,形成共价键型石墨层间化合物。氧化石墨烯的理想结构组成为C400H,也有文献报道其组成为C X+(OH)Y-(H20)2,其中C、H、O等各元素的含量随氧化程度不同而发生改变,一般范围为C7O4H2-C24O13H9,目前,普遍认为氧化石墨是一个准二维固体物质。氧化石墨烯由尺寸不定的未被氧化的芳香“岛”组成,而这些“岛”则被含有醇羟基、环氧基团和双键的六元脂环所分开,芳香环、双键和环氧基团使得碳原子点阵格式近乎处于同一平面,仅有连接到羟基基团的碳原子有较轻微的四面体构型畸变,导致了一些层面的卷翘。官能团处于碳原子点阵格子的上下,形成了不同密度的氧原子分布。 干燥的氧化石墨在空气中稳定性较差,很容易吸潮而变成水合氧化石墨,层间距也会随其含水量的高低而有所不同。随含水量的增加,层间距从0.6nm增加到1.1nm,从而导致X射线(100)衍射峰的位置的变化。 鉴于氧化石墨烯在石墨烯材料领域中的地位,许多科学家试图对氧化石墨烯的结构进行详细和准确的描述,以便有利于石墨烯材料的进一步研究,虽然已经利用了计算机模拟、拉曼光谱,核磁共振等手段对其结构进行分析,但由于种种原因(不同的制备方法,实验条件的差异以及不同的石墨来源对氧化石墨烯的结构都有一定的影响),氧化石墨烯的精确结构还无法得到确定。 二、氧化石墨烯的制备方法 氧化石墨烯的制备方法主要有Brodie、Staudenmaier和Hummers三种方法,它们都是用无机强质子酸(如浓硫酸、发烟硝酸或它们的混合物)处理原始石墨,将强酸小分子插入石墨层问,再用强氧化剂(如KMnO4、KC104等)对其进行氧化。 1、Brodie法 1898年Brodie采用发烟HNO3体系,以KC103为氧化剂,反应体系的温度需先维持在0℃,然后,不断搅拌反应20-24h。洗涤后获得的氧化石墨的氧化程度较低,需进行多次氧化处理以提高氧化程度,反应时间相对较长。该法的优点是其氧化程度可利用氧化时间进行控制,合成的氧化石墨结构比较规整。但因采用KC103作氧化剂,有一定的危险性。

石墨烯的制备与表征综述

氧化石墨烯还原的评价标准 摘要还原氧化石墨烯(RGO)是一种 有趣的有潜力的能广泛应用的纳米 材料。虽然我们花了相当大的努力 一直致力于开发还原方法,但它仍然 需要进一步改善,如何选择一个合适 的一个特定的还原方法是一个棘手 的问题。在这项研究中,还原氧化石 墨烯的研究者们准备了六个典型的 方法:N2H4·H2O还原,氢氧化钠还 原,NaBH4还原,水浴还原 ,高温还原以及两步还原。我们从四个方面系统的对样品包括:分散性,还原程度、缺陷修复程度和导电性能进行比较。在比较的基础上,我们提出了一个半定量判定氧化石墨烯还原的评价标准。这种评价标准将有助于理解氧化石墨烯还原的机理和设计更理想的还原方法。 引言 单层石墨烯,因为其不寻常的电子性质和应用于各个领域的潜力,近年来吸引了巨大的研究者的关注。目前石墨烯的制备方法,包括化学气相沉积(CVD)、微机械剥离石墨,外延生长法和液相剥离法。前三种方法因为其获得的石墨烯的产品均一性和层数选择性原因而受到限制。此外,这些方法的低生产率使他们不适合大规模的应用。大部分的最有前途生产的石墨烯的路线是石墨在液相中剥离氧化然后再还原,由于它的简单性、可靠性、大规模的能力生产、相对较低的材料成本和多方面的原因适合而适合生产。这种化学方法诱发各种缺陷和含氧官能团,如羟基和环氧导致石墨烯的电子特性退化。与此同时,还原过程可能导致发生聚合、离子掺杂等等。这就使得还原方法在化学剥离法发挥至关重要的作用。 到目前为止,我们花了相当大的努力一直致力于开发还原的方法。在这里我们展示一个简单的分类:使用还原剂(对苯二酚、二甲肼、肼、硼氢化钠、含硫化合物、铝粉、维生素C、环六亚甲基四胺、乙二胺(EDA) 、聚合电解质、还原糖、蛋白质、柠檬酸钠、一氧化碳、铁、去甲肾上腺素)在不同的条件(酸/碱、热处理和其他类似微波、光催化、声化学的,激光、等离子体、细菌呼吸、溶菌酶、茶溶液)、电化学电流,两步还原等等。这些不同的还原方法生成的石墨烯具有不同的属性。例如,大型生产水分散石墨烯可以很容易在没有表面活性稳定剂的条件下地实现由水合肼还原氧化石墨烯。然而,水合肼是有毒易爆,在实际使用的过程中存在困难。水浴还原方法可以减少缺陷和氧含量的阻扰。最近,两个或更多类型的还原方法结合以进一步提高导电率或其他性能。例如,水合肼还原经过热处理得到的石墨烯通常显现良好的导电性。

选择性还原氧化石墨烯

文章编号: 1007?8827(2014)01?0061?06 选择性还原氧化石墨烯 徐 超1, 员汝胜1, 汪 信2 (1.福州大学光催化研究所福建省重点实验室?国家重点实验室培育基地,福建福州350002; 2.南京理工大学教育部软化学与功能材料重点实验室,江苏南京210094) 摘 要: 还原氧化石墨烯已被广泛用于制备基于石墨烯的材料三目前,还原处理方法均是尽可能地将氧化石墨烯中的功能团去除,恢复石墨烯的电子结构三由于氧化石墨烯中氧基功能团(如羟基二羧基及环氧基)不同的反应活性,氧化石墨烯是可能通过分步的方法进行还原三利用醇溶剂如乙醇二乙二醇二丙三醇还原氧化石墨烯,并采用不同分析手段对样品进行表征三结果发现,在一定条件下这些醇可选择性地还原氧化石墨烯三经这些醇的处理后,氧化石墨烯中环氧功能团被大部分去除,而其他的功能团如羟基和羧基仍被保留三这种选择性去除氧化石墨烯表面功能团的方法可利于有效地控制氧化石墨烯的还原程度二获得具有特定功能团的石墨烯衍生物,从而扩大这类材料的使用范围三 关键词: 氧化石墨烯;氧化功能团;醇;选择性还原 基金项目:国家自然科学基金(21201036,21077023);福建省自然科学基金(2010J01035,2012J01039). 作者简介:徐 超,博士,讲师.E?mail:cxu@https://www.wendangku.net/doc/127530260.html, Selective reduction of graphene oxide XU Chao1, YUAN Ru?sheng1, WANG Xin2 (1.Research Institute of Photocatalysis,Fujian Provincial Key Laboratory of Photocatalysis??State Key Laboratory Breeding Base,Fuzhou University,Fuzhou350002,China; 2.Key Laboratory for Soft Chemistry and Functional Materials of Ministry Education,Nanjing University of Science and Technology,Nanjing210094,China) Abstract: The reduction of graphene oxide has been widely used to control the properties of graphene?based materials.Traditional methods thoroughly remove oxygenated functional groups in graphene oxides.We show that ethanol,ethylene glycol and glycerol can se?lectively reduce epoxy groups in graphene oxide while hydroxyl and carboxyl groups remain unchanged.Hydrazine hydrate can reduce ox?ygen functional groups except carboxyl groups.These selective removals can be used to control the reduction degree of graphene oxides and their properties.The electrical conductivity of the reduced graphene oxides with different types of oxygen functional groups varied sig?nificantly and increased with the degree of reduction. Keywords: Graphene oxide;Oxygenated functional groups;Alcohols;Selective reduction CLC number: TQ127.1+1Document code: A Received date:2013?07?10; Revised date:2013?12?22 Corresponding author:XU Chao,Ph.D,Lecturer.E?mail:cxu@https://www.wendangku.net/doc/127530260.html, Foundation items:National Natural Science Foundation of China(21201036,21077023);Natural Science Foundation of Fujian Province (2010J01035,2012J01039). English edition available online ScienceDirect(http:∕∕https://www.wendangku.net/doc/127530260.html,∕science∕journal∕18725805). DOI:10.1016/S1872?5805(14)60126?8 1 Introduction Graphene oxide(GO),utilized as precursor for a large?scale production of graphene?based materials,has attracted a great deal of attention in recent years[1?5]. GO sheets are electrically insulating,owing to their oxygenated functional groups(hydroxyl,carboxyl and epoxy groups)on surface,which usually need further treatments to restore the electrical conductivity for spe?cific applications[6].A lot of methods,such as chemi?cal reduction[7?9],laser irradiation[10,11],microwave ir?radiation[12,13],photocatalysis[14,15],solvothermal re?duction[16,17],have been explored to remove these atta?ched groups thoroughly and to recover graphene net?works of sp2bonds. Actually,researchers recently have found that the reduction degree of graphene oxide or oxidation degree of graphene has certain influences on their properties,such as electrical conductivity,catalysis activity and semi?conductive band positions[18?20]. Among these research work,the reduction degree of 第29卷 第1期 2014年2月新 型 炭 材 料 NEW CARBON MATERIALS Vol.29 No.1 Feb.2014

氧化石墨烯的制备及表征

氧化石墨烯的制备及表征 文献综述 材料0802班 李琳 200822046

氧化石墨烯的制备及表征 李琳 摘要:石墨烯(又称单层石墨或二维石墨)是单原子厚度的二维碳原子晶体,被认为是富勒烯、碳纳米管和石墨的基本结构单元[1]。石墨烯可通过膨胀石墨经过超声剥离或球磨处理来制备[2,3],其片层厚度一般只能达到30~100 nm,难以得到单层石墨烯(约0.34 nm),并且不容易重复操作。所以寻求一种新的、容易和可以重复操作的实验方法是目前石墨烯研究的热点。而将石墨氧化变成氧化石墨,再在超声条件下容易得到单层的氧化石墨溶液,再通过化学还原获得,已成为石墨烯制备的有效途径[4]。通过述评氧化石墨及氧化石墨烯的制备、结构、改性及其与聚合物的复合,展望了石墨烯及其复合材料的研究前景。 关键词:氧化石墨烯,石墨烯,氧化石墨,制备,表征 Oxidation of graphite surfaces preparation and Characterization LI Lin Abstrat:Graphite surfaces (also called single graphite or 2 d graphite )is the single atoms thickness of the 2 d carbon atoms crystal, is considered fullerenes, carbon nanotubes and graphite basic structure unit [1].Graphite surfaces can through the expanded graphite after ultrasonic stripping or ball mill treatment topreparation [2,3], a piece of layer thickness normally only up to 30 to 100 nm, hard to get the single graphite surfaces (about 0.34 nm), and not easy to repeated operation. So to search a new, easy to operate and can be repeated the experiment method of the graphite surfaces is the focus of research. And will graphite oxidization into oxidation graphite, again in ultrasonic conditions to get the oxidation of the single graphite solution, again through chemical reduction get, has become an effective way of the preparation of graphite surfaces [4]. Through the review of graphite oxide and oxidation graphite surfaces of the preparation, structure, modification of polymer and the

氧化石墨烯的制备方法总结

氧化石墨烯的制备方法: 方法一: 由天然鳞片石墨反应生成氧化石墨,大致分为3 个阶段,低温反应:在冰水浴中放入大烧杯,加入110mL 浓H2SO4,在磁力搅拌器上搅拌,放入温度计让其温度降至4℃左右。加入-100目鳞片状石墨5g,再加入NaNO3,然后缓慢加入15g KMnO4,加完后记时,在磁力搅拌器上搅拌反应90min,溶液呈紫绿色。中温反应:将冰水浴换成温水浴,在磁力搅拌器搅拌下将烧杯里的温度控制在32~40℃,让其反应30 min,溶液呈紫绿色。高温反应:中温反应结束之后,缓慢加入220mL 去离子水,加热保持温度70~100℃左右,缓慢加入一定双氧水(5 %)进行高温反应,此时反应液变成金黄色。反应后的溶液在离心机中多次离心洗涤,直至BaCl2检测无白色沉淀生成,说明没有SO42-的存在,样品在40~50℃温度下烘干。H2SO4、NaNO3、KMnO4一起加入到低温反应的优点是反应温度容易控制且与KMnO4反应时间足够长。如果在中温过程中加入KMnO4,一开始温度会急剧上升,很难控制反应的温度在32~40℃。技术路线图见图1。 方法二:Hummers 方法 采用Hummers 方法[5]制备氧化石墨。具体的工艺流程在冰水浴中装配好250 mL 的反应瓶加入适量的浓硫酸搅拌下加入2 g 石墨粉和1 g 硝酸钠的固体混合物再分次加入6 g 高锰酸钾控制反应温度不超过20℃搅拌反应一段时间然后升温到35℃左右继续搅拌30 min再缓慢加入一定量的去离子水续拌20 min 后并加入适量双氧水还原残留的氧化剂使溶液变为亮黄色。趁热过滤并用5%HCl 溶液和去离子水洗涤直到滤液中无硫酸根被检测到为止。最后将滤饼置于60℃的真空干燥箱中充分干燥保存备用。方法三:修正的Hummers方法 采用修正的Hummers方法合成氧化石墨,如图1中(1)过程。即在冰水浴中装配好250 mL的反应瓶,加入适量的浓硫酸,磁力搅拌下加入2 g 石墨粉和1 g硝酸钠的固体混合物,再缓慢加入6 g高锰酸钾,控制反应温度不超过10 ℃,在冰浴条件下搅拌2 h后取出,在室温下搅拌反应5 d。然后将样品用5 %的H2SO4(质量分数)溶液进行稀释,搅拌2 h后,加入6 mL H2O2,溶液变成亮黄色,搅拌反应2 h离心。然后用浓度适当的H2SO4、H2O2混合溶液以及HCl反复洗涤、最后用蒸馏水洗涤几次,使其pH~7,得到的黄褐色沉淀即为氧化石墨(GO)。最后将样品在40 ℃的真空干燥箱中充分干燥。将获得的氧化石墨入去离子水中,60 W功率超声约3 h,沉淀过夜,取上层液离心清洗后放入烘箱内40 ℃干燥,即得片层较薄的氧化石墨烯,如图1中(2)过程。

关于石墨烯的总结

一.石墨烯常用修饰方法总结 石墨烯是由一层密集的、包裹在蜂巢晶体点阵上的碳原子组成,是世界上最薄的二维材料,其厚度仅为0.35 nm。这种特殊结构蕴含了丰富而新奇的物理现象,使石墨烯表现出许多优异性质。 结构完整的石墨烯是由不含任何不稳定键的苯六元环组合而成的二维晶体,化学稳定性高,其表面呈惰性状态,与其他介质(如溶剂等)的相互作用较弱,并且石墨烯片与片之间有较强的范德华力,容易产生聚集,使其难溶于水及常用的有机溶剂,这给石墨烯的进一步研究和应用造成了极大的困难。为了充分发挥其优良性质,并改善其成型加工性(如提高溶解性、在基体中的分散性等),必须对石墨烯进行有效的功能化。通过引入特定的官能团,还可以赋予石墨烯新的性质,进一步拓展其应用领域。功能化是实现石墨烯分散、溶解和成型加工的最重要手段。 从功能化的方法来看。主要分为共价键功能化和非共价键功能化两种。 1. 石墨烯的共价功能化 石墨烯的共价键功能化是目前研究最为广泛的功能化方法。尽管石墨烯的主体部分由稳定的六元环构成,但其边沿及缺陷部位具有较高的反应活性,可以通过化学氧化的方法制备石墨烯氧化物(Grapheneoxide)。由于石墨烯氧化物中含有大量的羧基、羟基和环氧键等活性基团,可以利用多种化学反应对石墨烯进行共价键功能化。 1.1 石墨烯的聚合物功能化 (1)聚乙二醇(PEG)具有优异的生物相容性和亲水性,被广泛应用于多种不同的功能化纳米材料,以提高这些材料的生物相容性,减小其对生物分子及细胞的非特定的约束力,也改善了体内的药物代谢动力学,以实现更好的肿瘤靶向性治疗[1,2,3-5]。2008年,Dai 等使用六臂星型氨基聚乙二醇的端氨基与纳米石墨烯片边缘的羧基通过亚胺催化酰胺形成反应,制备PEG 修饰纳米石墨烯片,得到的产物在用于体外给药和生物成像的生理溶液中显示了优良的分散性和稳定性[2]。 (2)除了PEG外,还有其他的被用来共价功能化GO的亲水大分子。刘庄工作组,将氨基修饰的DEX与GO通过共价键键合,得到了具有生物相容性的材料,这种材料大大提高了GO生理溶解性的稳定性[6]。Bao et al.

氧化石墨烯的绿色还原方法

龙源期刊网 https://www.wendangku.net/doc/127530260.html, 氧化石墨烯的绿色还原方法 作者:肖祖萍 来源:《学校教育研究》2018年第14期 石墨烯是一种单原子层的碳二维纳米材料,它是由碳六元环组成的二维蜂窝状点阵结构,碳原子的排列与石墨原子层排列相同。地球上不缺少石墨材料,为制备石墨烯材料提供了充足的原材料。目前常用的石墨烯只要由两大类方法制备,一种是将石墨氧化为氧化石墨烯,再通过化学方法将氧化石墨烯还原为石墨烯。另一种是通过化学方法或某些操作将石墨直接转化为石墨烯。在本文主要研究第一种方法中的绿色还原方法。本文中的石墨烯都是由氧化石墨烯通过还原得到的。石墨烯是由碳原子按六边形晶格整齐排布而成的碳单质,结构非常稳定。因为石墨烯的晶格结构,常会被误认为它很僵硬,但实际上却并非如此。例如,石墨烯作为目前已知的力学强度最高的材料,并有可能作为添加剂广泛应用于新型高强度复合材料之中;石墨烯良好的导电性及其对光的高透过性又让它在透明导电薄膜的应用中独具优势,而这类薄膜在液晶显示以及太阳能电池等领域的应用至关重要。 一、氧化石墨烯的制备 氧化石墨烯即石墨烯的氧化物,它是由石墨粉末经化学氧化及剥离后的产物。氧化石墨烯一般由石墨经强酸氧化而得。主要有三种制备氧化石墨的方法:Brodie法、Staudenmaier法和Hummers法。其中Hummers法的制备过程的时效性相对较好而且制备过程中也比较安全。目前最常用的制取氧化石墨烯的方法是由一个修改过的Hummer方法制备的。 二、氧化石墨烯的还原 1.绿色还原法 随着社会的发展和人们都环境的关注,我们越来越需要研究一些绿色的还原方法。绿色的还原方法即在还原氧化石墨烯的过程中不使用有毒的还原剂或不产生对环境产生危害的物质。绿色还原法对环境不会有危害或危害几乎可以不计,并可以得到较好的石墨烯。但有些绿色还原法还存在无法大规模生产的弊端,无法在应用到工业生产中去。目前常见的绿色还原方法有水热热还原氧化石墨烯、电化学还原氧化石墨烯、柠檬酸钠还原氧化石墨烯法、超声辅助镍粉绿色还原制备石墨烯、氧化石墨热解膨胀氢气还原法等。下面我们对这几种绿色还原方法做一个介绍。 (1)水热热还原氧化石墨烯 水热热还原氧化石墨烯是指在密封的压力容器中,以水为溶剂,在高温、高压的条件下进行的化学反应。将氧化石墨烯溶解于溶剂中,在液相或超临界条件下,反应物分散且变得活

氧化石墨烯的制备

大学生创新训练项目 研究报告 项目名称:氧化石墨烯和磁性氧化石墨烯的制备及其吸附性的研究 项目类型:一般项目 项目年度:2014年 项目负责人:李柯学号:32012080015 负责人院(系):安全与环境工程学院环境工程系 专业(方向):环境工程 项目组成员:杨梦凡、杨舒、卢光远 指导教师:任冬梅 教务处制 二〇一五年 摘要

石墨烯是由单层碳原子排列组合而成,呈六边形网状结构,因其特殊的二维结构表现出许多优异的性质。而氧化石墨烯由于在表面及边缘上大量含氧基团的引入,易于修饰与功能化,且保持着化学稳定性。本文采用改良hummers法制备氧化石墨烯。本文采用改良hummers 法制备氧化石墨烯。改进后制备较高氧化程度的氧化石墨的原料:天然鳞片石墨1g,浓硫酸23ml,高锰酸钾3g,硝酸钠0.5g,30%双氧水10ml,35%的盐酸,蒸馏水若干(实验中采用了多组不同的原料用量配比,过程记录以此组数据为例)。并得到如下结论:制取氧化石墨烯时,一定范围内,天然鳞片石墨用量减少可以提高氧化程度;硝酸钠用量的变化对石墨烯氧化程度影响不大;适度增加高锰酸钾和双氧水的用量同样可以提高氧化程度。实验过程中,高锰酸钾对石墨烯的氧化起着至关重要的作用,加入高锰酸钾时长时间缓慢增加对石墨烯氧化程度的效果比一次性直接加入要好。改进后的方法有利于提高实验室合成氧化石墨烯的效率,一定程度上降低了实验操作的难度。制取磁性氧化石墨烯的过程中,是在强碱性(PH>12)的环境下,让氧化石墨烯与FeCl3和FeCl2水浴恒温,使生成的纳米Fe3O4直接镶嵌复合到氧化石墨烯上。最后在不同浓度的PH条件下测得氧化石墨烯和磁性氧化石墨烯对甲基橙和重金属离子的吸收。 关键词:氧化石墨烯、磁性氧化石墨烯、吸附性

还原氧化石墨烯横向尺寸分布影响因素初探_张天友

还原氧化石墨烯横向尺寸分布影响因素初探* 张天友,张东 (同济大学材料科学与工程学院,上海200092) 摘要:化学还原剥离氧化石墨法制备的还原氧化石墨烯具有诸多优异性能,但所得还原氧化石墨烯横向尺度差异较大。利用化学还原法制备了还原氧化石墨烯,基于还原氧化石墨烯的AFM观测结果,初步统计分析了静置、磁力搅拌、离心和超声处理及它们的次序对还原氧化石墨烯横向尺寸分布的影响,结果表明后述3个步骤及次序是影响斑点状(横向尺寸< 100nm@100nm)和树叶状(横向尺寸>500nm@ 500nm)还原氧化石墨烯横向尺寸分布的主要因素。 关键词:化学法;还原氧化石墨烯;磁力搅拌;超声处理;离心处理 中图分类号:TQ127.1文献标识码:A 文章编号:1001-9731(2009)10-1695-04 1引言 石墨烯是由碳原子构成的二维晶体,碳原子的排列方式与石墨中单原子层一致;该新型二维碳材料具有诸多优异的性能,自2004年被发现以来引起了研究人员的广泛关注[1,2]。目前常用的制备方法包括:微机械剥离法[3]、外延生长法[4]和化学法[5,6]。其中化学法的生产成本相对低廉,且可实现大量生产,成为目前研究的热点之一。该方法的基本思路是,在一定条件下剥离分散在某些极性介质氧化石墨为氧化石墨烯(gr aphene ox ide[7],GO),再经化学还原处理得到还原氧化石墨烯(reduced gr aphene oxide[8],RGO)。近期的研究结果表明,化学制备的RGO是一种p型半导体材料[9,10],使得RGO不仅可以用作纳米复合材料的增强相[2],而且有望用作纳米电子器件的原料[1,9,10]。但是由化学法生产的还原氧化石墨烯横向尺度差异较大,从几十纳米到数千纳米[5,7]。Ritter等人[11]的研究表明石墨烯形貌影响其能带结构,进而影响石墨烯在纳米电子器件领域中的应用,所以需对化学法制备的还原氧化石墨烯进行分离,以满足不同的应用需求。因此,对RGO横向尺寸影响因素的探讨,有助于缩小RGO横向尺寸分布方法的发现。本文利用化学法制备RGO,研究了静置、磁力搅拌、超声、离心处理以及它们的次序对RGO横向尺寸分布的影响。2实验 2.1主要试剂 浓硫酸(98%,CR),盐酸(AR),双氧水30% (AR),高锰酸钾(AR),鳞石墨(500目),水合肼85% (CR)。 2.2主要仪器 超声波细胞粉碎机(KS-600),台式低速离心机(80-2),电热恒温水浴锅(DK-S22)。 RGO的制备过程主要包括4个部分:(1)配制氧化石墨和去离子水的混合液(150ml,1mg/ml),并在磁力搅拌和静置处理不同阶段取样,得到样品?、ò和ó(图1);(2)制备GO溶胶,调整离心(10min,4000r/ min)和超声(10min)处理次序,得到样品A,B和C(图2);(3)以水合肼为还原剂在一定温度下还原所得GO 溶胶,得到样品A.、B.和C.(图3);(4)制备对比样品D.(图4)。实验所用氧化石墨由改进后的H umm er s 法[12] 制得。 图1样品?、ò、ó的制备流程图 Fig1The flow char t of preparing sample?,ò, ó 图2样品A、B、C的制备流程图 Fig2T he flow chart of preparing sample A,B, C 图3样品A.、B.、C.的制备流程图 Fig3The flo w chart of preparing sample A.,B.,C. *基金项目:国家高技术研究发展计划(863计划)资助项目(2009A A05Z419);教育部新世纪优秀人才支持计划资助项目(NCET-07-0626);上海市/科技创新行动计划0国际合作资助项目(0816*******) 收到初稿日期:2009-03-30收到修改稿日期:2009-08-03通讯作者:张东 作者简介:张天友(1981-),男,山东聊城人,在读博士,师承张东教授,从事纳米材料研究。

石墨烯氧化还原法

四:石墨烯的氧化还原法制备及结构表征 摘要:采用改进的 Hummers 法对天然鳞片石墨进行氧化处理制备氧化石墨,经超声分散,然后在水合肼的作用下加热还原制备了在水相条件下稳定分散的石墨烯。用红外光谱、拉曼光谱、扫描探针显微镜和ζ电位仪对样品进行了结构、谱学、形貌和ζ电位分析。结果表明,石墨被氧化后形成以 C=O、C-OH、-COOH 和 C-O-C 等官能团形式的共价键型石墨层间化合物;还原氧化石墨后形成的石墨烯表面的官能团与石墨的相似;氧化石墨烯和石墨烯在碱性条件下可形成稳定的悬浮液;氧化石墨烯和石墨烯薄片厚度为 1.0 nm 左右。考察并讨论了还原过程中水合肼用量,体系反应温度、反应时间和 pH 值对石墨烯还原程度和稳定性的影响,水合肼用量和反应时间是影响石墨烯还原程度的主要因素;pH 值对石墨烯稳定性影响较大。 实验部分 1.1原料:天然鳞片石墨(~74 μm);高锰酸钾,浓硫酸,水合肼 (50%),均为化学纯,市售;5% H2O2溶液,0.05mol · L-1HCl 溶液,体系的 pH 值用 0.1mol · L-1NaOH溶液调节。 1.2制备 氧化石墨制备:将 10 g 石墨、230 mL 98%浓硫酸混合置于冰浴中,搅拌 30 min,使其充分混合,称取 40 g KMnO4加入上述混合液继续搅拌 1 h 后,移入 40 ℃中温水浴中继续搅拌 30 min;用蒸馏水将反应液(控制温度在 100 ℃以下)稀释至 800~1 000mL 后加适量 5% H2O2,趁热过滤,用 5% HCl 和蒸馏水充分洗涤至接近中性,最后过滤、洗涤,在 60℃下烘干,得到氧化石墨样品。石墨烯制备:称取上述氧化石墨 0.05 g,加入到100 mL pH=11 的 NaOH 溶液中;在 150 W 下超声90 min 制备氧化石墨烯分散液;在 4000 r· min-1下离心 3 min 除去极少量未剥离的氧化石墨;向离心

氧化石墨烯的制备

氧化石墨烯的制备 案场各岗位服务流程 销售大厅服务岗: 1、销售大厅服务岗岗位职责: 1)为来访客户提供全程的休息区域及饮品; 2)保持销售区域台面整洁; 3)及时补足销售大厅物资,如糖果或杂志等; 4)收集客户意见、建议及现场问题点; 2、销售大厅服务岗工作及服务流程 阶段工作及服务流程 班前阶段1)自检仪容仪表以饱满的精神面貌进入工作区域 2)检查使用工具及销售大厅物资情况,异常情况及时登记并报告上级。 班中工作程序服务 流程 行为 规范 迎接 指引 递阅 资料 上饮品 (糕点) 添加茶水 工作 要求 1)眼神关注客人,当客人距3米距离 时,应主动跨出自己的位置迎宾,然后 侯客迎询问客户送客户

注意事项 15度鞠躬微笑问候:“您好!欢迎光临!”2)在客人前方1-2米距离领位,指引请客人向休息区,在客人入座后问客人对座位是否满意:“您好!请问坐这儿可以吗?”得到同意后为客人拉椅入座“好的,请入座!” 3)若客人无置业顾问陪同,可询问:请问您有专属的置业顾问吗?,为客人取阅项目资料,并礼貌的告知请客人稍等,置业顾问会很快过来介绍,同时请置业顾问关注该客人; 4)问候的起始语应为“先生-小姐-女士早上好,这里是XX销售中心,这边请”5)问候时间段为8:30-11:30 早上好11:30-14:30 中午好 14:30-18:00下午好 6)关注客人物品,如物品较多,则主动询问是否需要帮助(如拾到物品须两名人员在场方能打开,提示客人注意贵重物品); 7)在满座位的情况下,须先向客人致歉,在请其到沙盘区进行观摩稍作等

待; 阶段工作及服务流程 班中工作程序工作 要求 注意 事项 饮料(糕点服务) 1)在所有饮料(糕点)服务中必须使用 托盘; 2)所有饮料服务均已“对不起,打扰一 下,请问您需要什么饮品”为起始; 3)服务方向:从客人的右面服务; 4)当客人的饮料杯中只剩三分之一时, 必须询问客人是否需要再添一杯,在二 次服务中特别注意瓶口绝对不可以与 客人使用的杯子接触; 5)在客人再次需要饮料时必须更换杯 子; 下班程 序1)检查使用的工具及销售案场物资情况,异常情况及时记录并报告上级领导; 2)填写物资领用申请表并整理客户意见;3)参加班后总结会; 4)积极配合销售人员的接待工作,如果下班时间已经到,必须待客人离开后下班;

氧化还原法制备石墨烯的方法概述

(2) (2) Abstract (2) Key words (2) I (3) (3) 2.1 GO (4) 2.1.1Brodie (5) 2.1.2 Staudenmaier (6) 2.1.3 Hummers (6) 2.2 GO (6) 2.2.1 (6) 2.2.2 (7) 2.2.3 . (7) 2.2.4 (7) (9) (10) (13)

, The Summarize of oxidation-reduction method for graphene Shaoqing Ma , Zhongai Hu (Northwest normal university, chemical engineering college, lanzhou, 730070) Abstract : In recent years, graphene with its unique structure and the outstanding performance, caused wide interests in the chemical, physical and material fields. People have made positive progress in the preparation of graphene,and have provided raw material guarantee for graphene of basic research and application development. This paper largely applied the latest references in recent years , reviewed the legal system with oxidation-reduction method for graphene and presented the development prospects. Key words : graphite oxide, graphene, oxidation-reduction method I

石墨烯和氧化石墨烯作为新的纳米载体在药物输送方面的应用

石墨烯和氧化石墨烯作为新的纳米载体在药物输送方面的应用摘要 在过去的几年里,石墨烯材料在生物医学方面的应用(包括药物输送)发展迅速。由于其独特的性质:二维的平面结构、巨大的表面积、化学和机械稳定性、极好的导电性和良好的生物相容性,作为在生物医药方面最有前景的生物材料之一,石墨烯和氧化石墨烯受到了广泛的研究。这些特性使得在先进的药物输送系统的设计和提供广泛的治疗输送方面有领号的应用前景。在这篇评论中,我们概述了该领域的最新研究进展,并简要描述了当前对于石墨烯材料纳米载体及其生物相容性和毒性的改性方法。紧随其后的是对一些诱人例子的概括总结,这些例子证实了它们对抗癌药物和基因输送的可行性。此外,我们还对基于控制机理的新的药物输送概念进行了讨论,其中包括靶向目标和pH值的模拟,化学相互作用,热、光和磁感应等。最后,本文总结了所述内容,对该领域未来的发展前景和挑战得出了一个简要结论。 1.引言 开发新的和有效的药物输送系统,以改善治疗药物的治疗概况和疗效是现代医学所面临的关键问题之一。纳米科学和纳米技术的进步,使得新的纳米材料得以合成,促进了许多新药物输送系统的发展。近年来石墨烯的发现引起了人们日益增加研究关注,来探索这种新材料在药物输送方面的应用。石墨烯是碳原子SP2杂化堆积成的单层二维蜂窝状晶格结构,自从2004年被发现以来,它已经引起了整个科学界的巨大兴趣。由于其独特的化学结构和几何结构,石墨烯具有非凡的物理化学性质, 包括高杨氏模量、高断裂强度、优异的导热和导电能力、载荷子的快速迁移率、高比表面积和良好的生物相容性。这些性质使得石墨烯在广泛的应用范围中都是理想的材料,包括量子物理学、纳米电子学、能源研究,纳米复合材料的催化和工程和生物材料等。在生物医药领域,作为一种新的生物材料石墨烯及其复合物在广泛的应用范围上提供了令人兴奋的机遇,包括新一代生物传感器、药物输送载体、细胞和生物成像探针。 石墨烯是其他石墨材料的基本构建单位,可构成具有不同几何图形的石墨材料(图1),如绕成球形结构(零维富勒烯),卷成一维结构(碳纳米管)或堆积成三维层状结构(石墨)。以这种角度来考虑,石墨烯类似于富勒烯和碳纳米管,只是层数、直径、长度和表面化学不同。石墨烯由单层的六元环π-π共轭结构构成,在概念上可视为平面芳香高分子。这种平面结构使其有能力固定大量的物质,包括金属、药物、生物分子、荧光探针和细胞。因此,毫不奇怪石墨烯在纳米医学和生物医学应用中引起了人们巨大的兴趣,经过适当改性的石墨烯可以作为一个很好的药物输送平台并用于抗癌药物/基因、生物传感、生物成像、抗菌应用、细胞培养和组织工程等。与碳纳米管相比,石墨烯表现出某些重要的性质,如价格低廉、可表面修饰、比表面积大、不含有毒金属离子。因此,石墨烯已经开始威胁到碳纳米管在许多应用中的统治地位,包括药物输送,并表现出低毒性和高生物相容性。在给药的情况下,一个例子是石墨烯纳米材料的载药比例(装载药物和载体的重量比)可以达到200%,与纳米粒子和其他药物输送系统相比,这个比例是相当高。戴的小组在2008年首创工作证明,通过非共价键的物理吸附,聚乙二醇功能化的氧化石墨烯可以用作一种新型的药物纳米载体来装载抗癌药物并具

还原氧化石墨烯横向尺寸分布影响因素初探

还原氧化石墨烯横向尺寸分布影响因素初探3 张天友,张 东 (同济大学材料科学与工程学院,上海200092) 摘 要: 化学还原剥离氧化石墨法制备的还原氧化石墨烯具有诸多优异性能,但所得还原氧化石墨烯横向尺度差异较大。利用化学还原法制备了还原氧化石墨烯,基于还原氧化石墨烯的A FM观测结果,初步统计分析了静置、磁力搅拌、离心和超声处理及它们的次序对还原氧化石墨烯横向尺寸分布的影响,结果表明后述3个步骤及次序是影响斑点状(横向尺寸< 100nm×100nm)和树叶状(横向尺寸>500nm×500nm)还原氧化石墨烯横向尺寸分布的主要因素。 关键词: 化学法;还原氧化石墨烯;磁力搅拌;超声处理;离心处理 中图分类号: TQ127.1文献标识码:A 文章编号:100129731(2009)1021695204 1 引 言 石墨烯是由碳原子构成的二维晶体,碳原子的排列方式与石墨中单原子层一致;该新型二维碳材料具有诸多优异的性能,自2004年被发现以来引起了研究人员的广泛关注[1,2]。目前常用的制备方法包括:微机械剥离法[3]、外延生长法[4]和化学法[5,6]。其中化学法的生产成本相对低廉,且可实现大量生产,成为目前研究的热点之一。该方法的基本思路是,在一定条件下剥离分散在某些极性介质氧化石墨为氧化石墨烯(grap hene oxide[7],GO),再经化学还原处理得到还原氧化石墨烯(reduced grap hene oxide[8],R GO)。近期的研究结果表明,化学制备的R GO是一种p型半导体材料[9,10],使得R GO不仅可以用作纳米复合材料的增强相[2],而且有望用作纳米电子器件的原料[1,9,10]。但是由化学法生产的还原氧化石墨烯横向尺度差异较大,从几十纳米到数千纳米[5,7]。Ritter等人[11]的研究表明石墨烯形貌影响其能带结构,进而影响石墨烯在纳米电子器件领域中的应用,所以需对化学法制备的还原氧化石墨烯进行分离,以满足不同的应用需求。因此,对R GO横向尺寸影响因素的探讨,有助于缩小R GO横向尺寸分布方法的发现。本文利用化学法制备R GO,研究了静置、磁力搅拌、超声、离心处理以及它们的次序对R GO横向尺寸分布的影响。2 实 验 2.1 主要试剂 浓硫酸(98%,CR),盐酸(A R),双氧水30% (AR),高锰酸钾(A R),鳞石墨(500目),水合肼85% (CR)。 2.2 主要仪器 超声波细胞粉碎机(KS2600),台式低速离心机(8022),电热恒温水浴锅(D K2S22)。 R GO的制备过程主要包括4个部分:(1)配制氧化石墨和去离子水的混合液(150ml,1mg/ml),并在磁力搅拌和静置处理不同阶段取样,得到样品Ⅰ、Ⅱ和Ⅲ(图1);(2)制备GO溶胶,调整离心(10min,4000r/ min)和超声(10min)处理次序,得到样品A,B和C(图2);(3)以水合肼为还原剂在一定温度下还原所得GO 溶胶,得到样品A’、B’和C’(图3);(4)制备对比样品D’(图4)。实验所用氧化石墨由改进后的Hummers 法[12]制得 。 图1 样品Ⅰ、Ⅱ、Ⅲ的制备流程图 Fig1The flow chart of p reparing sampleⅠ,Ⅱ, Ⅲ 图2 样品A、B、C的制备流程图 Fig2The flow chart of preparing sample A,B, C 图3 样品A’、B’、C’的制备流程图 Fig3The flow chart of preparing sample A’,B’,C’ 3基金项目:国家高技术研究发展计划(863计划)资助项目(2009AA05Z419);教育部新世纪优秀人才支持计划资助项目(NCET20720626);上海市“科技创新行动计划”国际合作资助项目(0816*******) 收到初稿日期:2009203230收到修改稿日期:2009208203通讯作者:张 东 作者简介:张天友 (1981-),男,山东聊城人,在读博士,师承张东教授,从事纳米材料研究。