AATCC 61-2009 水洗色牢度:快速法

Developed in 1950 by AATCC Committee RA60; revised 1952, 1954, 1957, 1960, 1961, 1970, 1972, 1986 (title change), 1989, 1993, 1994, 1996, 2003, 2006 (title change), 2007, 2009; reaffirmed 1956, 1962, 1965, 1968, 1969, 1975, 1980, 1985; editorially revised 1973, 1974, 1975, 1976, 1981, 1983, 1984, 1991, 1995, 1998, 2002, 2004, 2008; editorially revised and reaffirmed 2001. Partly equivalent to ISO 105-C06.

1.Purpose and Scope

1.1These accelerated laundering tests are to evaluate the colorfastness to laun-dering of textiles which are expected to withstand frequent laundering. The fabric color loss and surface changes resulting from detergent solution and abrasive ac-tion of five typical hand or home launder-ings, with or without chlorine, are roughly approximated by one 45 min test (see 9.2-9.6). However, the staining ef-fect produced by five typical hand or home launderings cannot always be pre-dicted by the 45min test. Staining is a function of the ratio of colored to undyed fabrics, fiber content of fabrics in the wash load and other end-use conditions which are not always predictable.

1.2 When this test method was origi-nally developed, various options of this method were intended to evaluate the color change and staining by five home or commercial launderings, on an accel-erated basis. Throughout the years, com-mercial laundering procedures have changed and commercial cleaning today involves many different types of pro-cesses, dependent on the type of product being cleaned that cannot be duplicated by one accelerated laboratory procedure. In 2005, all references to commercial laundering were removed as it is not known if these procedures accurately rep-licate typical commercial laundering pro-cesses used today.

2. Principle

2.1Specimens are tested under appro-priate conditions of temperature, deter-gent solution, bleaching and abrasive ac-tion such that the color change is similar to that occurring in five hand or home launderings. The color change is obtained in a conveniently short time. The abra-sive action is a result of the frictional ef-fects of fabric against canister, the low li-quor ratio and the impact of the steel balls on the fabric.

3. Terminology

3.1colorfastness, n.—the resistance of

a material to change in any of its color

characteristics, to transfer of its color-

ant(s) to adjacent materials or both, as a

result of the exposure of the material to

any environment that might be encoun-

tered during the processing, testing, stor-

age or use of the material.

3.2laundering, n.—of textile mate-

rials, a process intended to remove soils

and/or stains by treatment (washing) with

an aqueous detergent solution and nor-

mally including subsequent rinsing, ex-

tracting and drying.

4. Safety Precautions

NOTE: These safety precautions are

for information purposes only. The pre-

cautions are ancillary to the testing proce-

dures and are not intended to be all inclu-

sive. It is the user’s responsibility to use

safe and proper techniques in handling

materials in the test method. Manufactur-

ers MUST be consulted for specific de-

tails such as material safety data sheets

and other manufacturer’s recommenda-

tions. All OSHA standards and rules

must also be consulted and followed.

4.1Good laboratory practices should

be followed. Wear safety glasses in all

laboratory areas.

4.2All chemicals should be handled

with care.

4.3The 1993 AATCC Standard Refer-

ence Detergent WOB may cause irrita-

tion. Care should be taken to prevent ex-

posure to skin and eyes.

4.4An eyewash/safety shower should

be located nearby for emergency use.

4.5Manufacturer’s safety recommen-

dations should be followed when operat-

ing laboratory testing equipment.

5. Apparatus, Reagents and Materials

(see 12.1)

5.1Accelerated laundering machine.

5.1.1A laundering machine for rotat-

ing closed canisters in a thermostatically

controlled water bath at 40 ± 2 rpm.

5.1.2Stainless steel lever lock canis-

ters Type 1 500 mL (1 pt), 75 × 125 mm

(3.0 × 5.0 in.) for Test No. 1A.

5.1.3Stainless steel lever lock canisters

Type 2 1200 mL, 90 × 200 mm (3.5 × 8.0

in.) for Tests No. 1B, 2A, 3A, 4A and 5A.

5.1.4Adapter plates for holding canisters

(see 5.1.3) on laundering machine shaft.

5.1.5Stainless steel balls, 6 mm (0.25

in.) in diameter.

5.1.6 White Synthetic (SBR) Rubber

Balls 9-10 mm (3/8 in.) dia. 70 Durome-

ter hardness for Test 1B (see 12.1)

5.1.7Teflon fluorocarbon gaskets (see

7.4.2 and 12.2).

5.1.8Preheater/storage module (see

7.4, 12.1 and 12.3).

5.2Scales for rating test results.

5.2.1AA TCC Chromatic Transference

Scale (see 12.4).

5.2.2Gray Scale for Color Change (see

12.4).

5.2.3Gray Scale for Staining (see

12.4).

5.3Reagents and materials.

5.3.1Multifiber test fabrics (8 mm

[0.33 in.] filling bands) containing ace-

tate, cotton, nylon, silk, viscose rayon

and wool. Multifiber test fabrics (8 mm

[0.33 in.] filling bands) and (15 mm [0.6

in.] filling bands) containing acetate, cot-

ton, nylon, polyester, acrylic and wool

(see 12.5).

5.3.2 Bleached cotton test fabric, 32 ×

32 ends × picks/cm (80 × 80 ends ×

picks/in.) construction, 100 ± 3 g/m2 (3.0

± 0.1 oz/yd2), desized without fluorescent

whitening agent (see 12.5).

5.3.31993 AATCC Standard Refer-

ence Detergent WOB (without fluores-

cent whitening agent and without phos-

phate) or 2003 AATCC Standard

Reference Liquid Detergent WOB (see

10.5 and 12.7).

5.3.41993 AATCC Standard Refer-

ence Detergent (with fluorescent whiten-

ing agent) (see 10.5 and 12.6).

5.3.5Water, distilled or deionized (see

12.8).

5.3.6Sodium hypochlorite (NaOCl)

bleach (see 12.9).

5.3.7Sulfuric acid (H

2

SO

4

), 10% (see

12.9.1).

5.3.8Potassium iodide (KI), 10% (see

12.9.1).

5.3.9Sodium thiosulfate (Na2S2O3),

0.1N (see 12.9.1).

5.3.10Crockmeter test cloth cut in 50

mm (2 in.) squares (see 12.10).

5.3.11White cards (specimen mounts)

with Y tristimulus value at least 85%.

6. Test Specimens

6.1The sizes of the specimens required

for the various tests are as follows:

50 × 100 mm (2.0 × 4.0 in.) for Test

No. 1A,

50 × 150 mm (2.0 × 6.0 in.) for Tests

No. 1B, 2A, 3A, 4A and 5A.

6.2Test only one specimen in each

canister.

AATCC Test Method 61-2009

Colorfastness to Laundering: Accelerated

6.2.1Test one specimen per laboratory sample. Replication may be advisable for improved precision.

6.3To determine staining in Tests No. 1A and 2A, use multifiber test fabric. To determine staining in Test No. 3A, use ei-ther multifiber test fabric or bleached cot-ton test fabric. With respect to Test No. 3A, the use of multifiber test fabric is optional but the staining of acetate, nylon, polyester and acrylic is disregarded unless one of these fibers is present in the fabric being tested or known to be in the final garment. For Test 3A, multifiber test fabric with heat-sealed edges is recommended. Stain-ing is not determined in Tests No. 4A and 5A (see 12.11 and 12.12).

6.4Specimen preparation.

6.4.1Preparation with multifiber test fabric with individual component bands 8mm (0.33 in.) wide or with bleached cotton test fabric. Prepare pieces with a 50 mm (2.0 in.) square of multifiber test fabric cloth or bleached cotton test fabric (as required) sewn, stapled or suitably attached along one 50 mm (2.0 in.) edge of the test specimen and in contact with the face of the material. When multifiber test fabric is used, attach it so that each of the six fiber bands is along the 50 mm (2.0in.) edge of the specimen with the wool on the right. The fiber bands in the multifiber test fabric will be parallel to the lengthwise direction of the test specimen.

6.4.2Preparation with multifiber test fabric with individual component bands

15 mm (0.6 in.) wide. Prepare pieces with

a 50 × 100 mm (2.0 × 4.0 in.) rectangle of multifiber test fabric sewn, stapled or suitably attached centered along one 100 mm (4.0 in.) or 150 mm (6.0 in.) edge of the test specimen and in contact with the face of the material. Attach it so that each of the six fiber bands will be parallel to the widthwise direction of the specimen. Attach and secure the wool band at the top of the specimen to avoid fiber loss. 6.4.3It is recommended that knitted fabrics be sewn or stapled at the four edges to equivalent size pieces of bleached cotton test fabric to avoid rolled edges and to assist in obtaining a uniform test result over the entire surface. Attach the multifiber test fabric to the face of the knitted fabric.

6.4.4For pile fabric specimens with a pile lay direction, attach the multifiber test fabric at the top of the specimen with the pile lay direction pointing away from the top of the specimen.

6.5When the textile to be tested is yarn, specimens may be tested using Op-tion 1 or Option 2.

6.5.1Option 1. Knit yarn on an appro-priate sample knitting machine. Prepare specimens and multifiber test fabrics ac-cording to 6.1-6.4.3. Keep one knitted specimen of each sample as an unwashed original.

6.5.2Option 2. Prepare two 110 m

(120 yd) skeins of each yarn. Fold the

skein so that there is a uniform amount of

yarn across a 50 mm (2 in.) width with a

length appropriate for the procedure to be

used. Keep one skein of each sample as

an unwashed original. Sew or staple

Crockmeter test cloth squares (see 12.10)

or squares of bleached cotton test fabric

having approximately the same weight

folded over each end of the layered yarn

specimen. Attach a multifiber test fabric

according to 6.4.1 or 6.4.2.

7. Procedure

7.1Table I summarizes the conditions

of the tests.

7.2Adjust the laundering machine to

maintain the designated bath tempera-

ture. Prepare the required volume of

wash liquor. Preheat this solution to the

prescribed temperature.

7.3Run Test No. 1A in 75 × 125 mm

(3.0 × 5.0 in.) lever lock stainless steel

canisters. Run Tests No. 2A, 3A, 4A and

5A in 90 × 200 mm (3.5 × 8.0 in.) lever

lock stainless steel canisters.

7.3.1For Tests No. 1A, 1B, 2A and

3A, add to the canister the amount of de-

tergent solution designated in Table I.

7.3.2For Test No. 4A, prepare a 1500

ppm available chlorine solution. For 1 L,

determine the amount of stock sodium

hypochlorite bleach solution (see 12.9) to

dilute as follows:

159.4/% NaOCl = g to add

Weigh the correct amount of bleach into a

volumetric flask and dilute to 1 L. To

each canister, add 5 mL of 1500 ppm

available chlorine solution and 45 mL of

detergent solution making a total volume

of 50 mL.

7.3.3For Test No. 5A, determine the

amount of stock sodium hypochlorite

bleach solution (see 12.9) to dilute as

follows:

4.54/% NaOCl = g to add

Weigh the correct amount of bleach into a

graduated cylinder and add detergent so-

lution to make a total volume of 150 mL.

Prepare this solution separately for each

canister.

7.3.4For all the tests, add the desig-

nated number of stainless steel balls or

white rubber balls to each canister.

7.4The two options for preheating the

canisters to the test temperature are by

use of the laundering machine or the pre-

heater/storage unit. If the canisters are to

be preheated in the laundering machine,

proceed to 7.4.2.

7.4.1Place the canisters in the pre-

heater module at the prescribed test tem-

perature. They are to remain in the

module for at least 2 min. Enter a well

crumpled test specimen into each canister.

7.4.2Clamp the covers on the canis-

ters. A Teflon fluorocarbon gasket (see

5.1.6) may be inserted between the neo-

prene gasket and the top of each canister

to prevent contamination of the wash so-

lution by the neoprene. Fasten the 75 ×

125 mm (3.0 × 5.0 in.) lever lock canis-

ters vertically and the 90 × 200 mm (3.5

× 8.0 in.) lever lock canisters horizontally

in the adapters on the rotor of the laun-

dering machine in such a manner that

when the canisters rotate, the covers

strike the water first. Place an equal num-

ber of canisters on each side of the shaft.

For canisters preheated in the module,

proceed to 7.7.

7.5Start the rotor and run it for at least

2 min to preheat the canisters.

7.6Stop the rotor and with a row of

canisters in an upright position, unclamp

the cover of one canister, enter a well

crumpled test specimen into the solution

and replace the cover, but do not clamp it.

Repeat this operation until all the canis-

ters in the row have been loaded. Then

clamp the covers in the same order in

which the canisters were loaded (delay

clamping the covers to allow equalization

of pressure). Repeat this operation until

all rows of canisters have been loaded.

7.7Start the laundering machine and

run it at 40 ± 2 rpm for 45 min.

7.8The rinsing, extracting and drying

procedures are the same for all the tests.

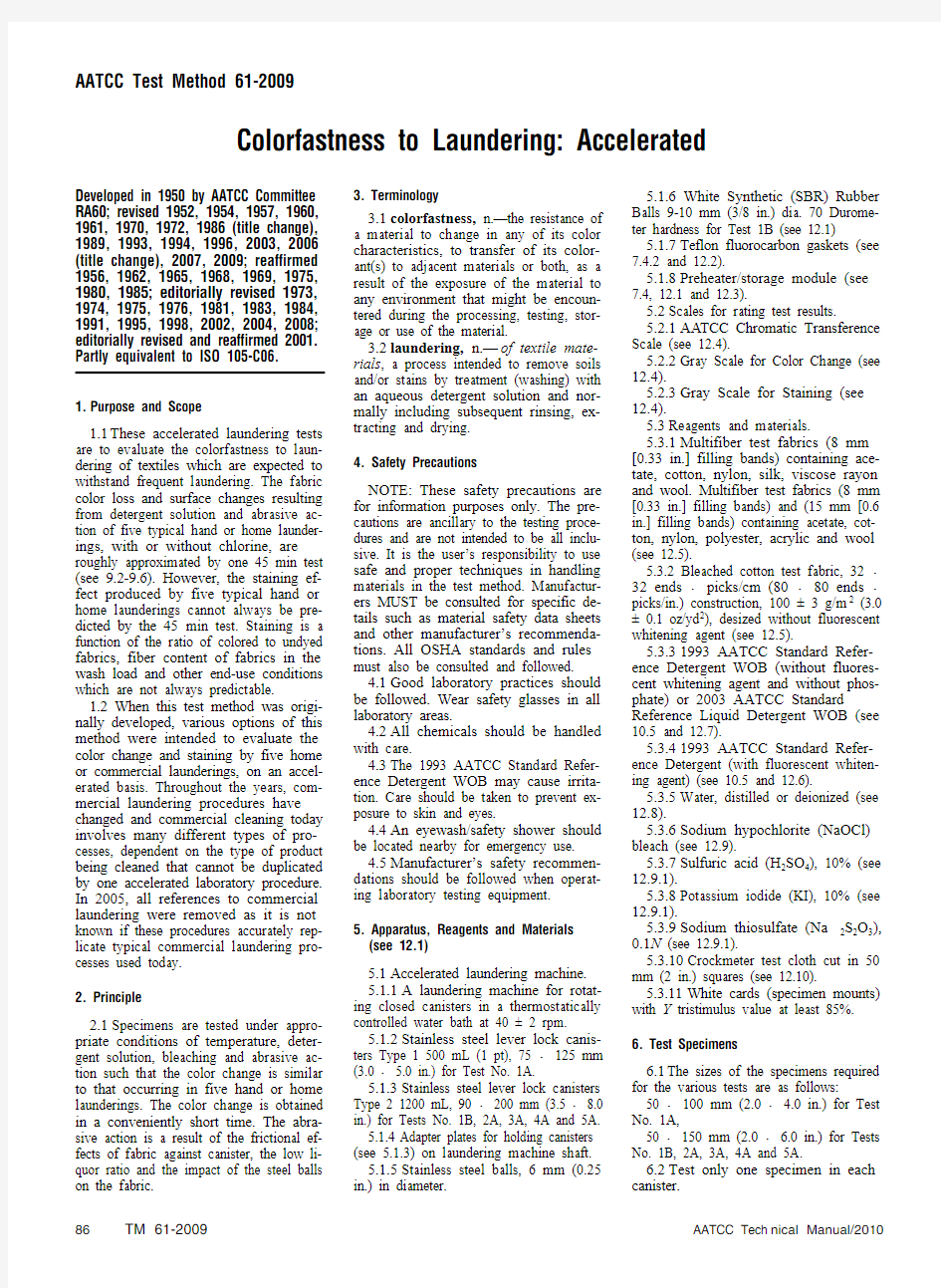

Table I—Test Conditions a

Test

No.

Temp Total

Liquor

Volume

(mL)

Percent

Powder

Detergent

of Total

Volume

Percent

Liquid

Detergent

of Total

Volume

Percent

Available

Chlorine

of Total

Volume

No.

Steel

Balls

No. of

Rubber

Balls

Time

(Min)°C (±°2)°F (±°4)

1A401052000.37None1045

b1B b31881500.370.56None1020

2A491201500.15None5045

3A71160500.15None10045

4A71160500.150.01510045

5A491201500.150.0275045

a Refer to Section 9 for objectives for each test method.

b Test 1B is the first test that includes the use of the standard liquid detergent and the use of Rubber Balls instead of Stainless Steel Balls.

Stop the machine, remove the canisters and empty the contents into beakers, keeping each test specimen in a separate beaker. Rinse each test specimen three times, in beakers, in distilled or deionized water at 40 ± 3°C (105 ± 5°F) for 1 min periods with occasional stirring or hand squeezing. To remove excess water, cen-trifuge, blot or pass the test specimens through wringer rolls. Dry the specimens in an air circulating oven in which the temperature does not exceed 71°C (160°F), or tumble dry in a nylon mesh bag in an automatic tumble dryer at nor-mal cycle, which has an exhaust tempera-ture of 60-71°C (140-160°F), or air dry.

7.9 Allow specimens to condition at 65± 2% relative humidity and 21 ± 1°C (70± 2°F) for 1 h before evaluating.

7.10Prepare tested fabric specimens and adjacent fabrics for evaluation by trimming off raveled yarns and lightly brushing off any loose fiber and yarn on the fabric surfaces. Brush pile fabric specimens in required direction to restore them as nearly as possible to the same pile angle as the untreated specimens. Specimens should be smoothed or flat-tened if they are wrinkled and messy due to washing and/or drying. Specimens may be mounted on cards to facilitate identification and handling in their evalu-ation. For consistency in backing mate-rial, use a white mounting card with Y tristimulus value of at least 85%. Mount-ing material must not be visible in the area to be viewed and must not interfere with rating as specified in 5.1 of both AATCC Evaluation Procedures 1 and 2 for the Gray Scale for Color Change and Gray Scale for Staining or instrumental assessment of color according to AATCC Evaluation Procedure 7, Instrumental As-sessment of the Change in Color of a Test Specimen (see 12.4).

7.10.1Yarn skein specimens should be combed and brushed for improved align-ment of the yarns before comparison with the unwashed original. The original spec-imens may also need further combing and brushing for uniformity of appearance.

8. Evaluation

8.1Evaluation of color change.

8.1.1Evaluate the color change of the test specimens as directed in AATCC Evaluation Procedure 1 using the Gray Scale for Color Change. For improved precision and accuracy the specimens should be rated by more than one rater. Grade 5—negligible or no change as shown in Gray Scale Step 5.

Grade 4.5—change in color equivalent to Gray Scale Step 4-5.

Grade 4—change in color equivalent to Gray Scale Step 4.

Grade 3.5—a change in color equiva-lent to Gray Scale Step 3-4.

Grade 3—change in color equivalent

to Gray Scale Step 3.

Grade 2.5—change in color equivalent

to Gray Scale Step 2-3.

Grade 2—change in color equivalent

to Gray Scale Step 2.

Grade 1.5—change in color equivalent

to Gray Scale Step 1-2.

Grade 1—change in color equivalent

to Gray Scale Step 1.

8.1.2The color change can be quanti-

tatively determined by measuring the

color difference between the unwashed

sample and a test specimen using a suit-

able colorimeter or spectrophotometer

with the appropriate software (see

AATCC Evaluation Procedure 7, Instru-

mental Assessment of the Change in

Color of a Test Specimen).

8.2Evaluation of staining.

8.2.1Evaluate staining (see 12.11) as

directed in AA TCC Evaluation Procedure

2 using the Gray Scale for Staining or as

directed in AA TCC Evaluation Procedure

8 using the Chromatic Transference

Scale. The scale used should be indicated

when reporting the test results.

Grade 5—negligible or no color transfer.

Grade 4.5—color transfer equivalent to

Step 4-5 on the Gray Scale for Staining or

Row 4.5 on the 9-step AA TCC Chro-

matic Transference Scale.

Grade 4—color transfer equivalent to

Step 4 on the Gray Scale for Staining or

Row 4 on the 9-step AATCC Chromatic

Transference Scale.

Grade 3.5—color transfer equivalent to

Step 3-4 on the Gray Scale for Staining or

Row 3.5 on the 9-step AA TCC Chro-

matic Transference Scale.

Grade 3—color transfer equivalent to

Step 3 on the Gray Scale for Staining or

Row 3 on the 9-step AATCC Chromatic

Transference Scale.

Grade 2.5—color transfer equivalent to

Step 2-3 on the Gray Scale for Staining or

Row 2.5 on the 9-step AA TCC Chro-

matic Transference Scale.

Grade 2—color transfer equivalent to

Step 2 on the Gray Scale for Staining or

Row 2 on the 9-step AATCC Chromatic

Transference Scale.

Grade 1.5—color transfer equivalent to

Step 1-2 on the Gray Scale for Staining or

Row 1.5 on the 9-step AA TCC Chro-

matic Transference Scale.

Grade 1—color transfer equivalent to

Step 1 on the Gray Scale for Staining or

Row 1 on the 9-step AATCC Chromatic

Transference Scale.

8.2.2The color transferred to the multi-

fiber test fabric or bleached cotton test

fabric square of 6.4.1 can be quantita-

tively determined by measuring the color

difference between a piece of the original

material and the stained material. Multifi-

ber test fabrics (15 mm [0.6 in.]) have fill-

ing bands of sufficient width to be within

the aperture diameter capability of many

colorimeters and spectrophotometers (see

AATCC Evaluation Procedure 6, Instru-

mental Color Measurement and 12.15).

9. Interpretation of Results

9.1Results from these tests are in-

tended to approximate the color change

effects (see 1.1) of five typical home

launderings. These are accelerated tests,

and in obtaining the required degree of

acceleration some of the conditions, such

as temperature, were purposely exagger-

ated. The tests have remained largely the

same over many years while laundry de-

tergents, washers and dryers, laundry

practices and fabrics have changed (see

AATCC monograph “Standardization of

Home Laundry Test Conditions,” else-

where in this T ECHNICAL M ANUAL).

Consequently, caution in interpreting test

results is advisable.

9.2 Test No. 1A—This test is for evalu-

ating the colorfastness of textiles that are

expected to withstand repeated hand

laundering at low temperature. Speci-

mens subjected to this test should show

color change similar to that produced by

five typical careful hand launderings at a

temperature of 40 ± 3°C (105 ± 5°F).

9.3 Test No. 1B—This test is for evalu-

ating the colorfastness of textiles that are

expected to withstand repeated hand

laundering at cool temperatures. Speci-

mens subjected to this test should show

color change similar to that produced by

five typical careful hand launderings at a

temperature of 27 ± 3°C (80 ± 5°F).

9.4 Test No. 2A—This test is for eval-

uating the colorfastness to washing of

textiles that are expected to withstand re-

peated low temperature machine launder-

ing in the home. Specimens subjected to

this test should show color change similar

to that produced by five home machine

launderings at medium or warm setting in

the temperature range of 38 ± 3°C (100 ±

5°F).

9.5 Test No. 3A—This test is for evalu-

ating colorfastness to washing of textiles

considered washable under vigorous con-

ditions. Specimens subjected to this test

should show color change similar to that

produced by five home machine launder-

ings at 60 ± 3°C (140 ± 5°F), without

chlorine.

9.6 Test No. 4A—This test is for evalu-

ating the colorfastness to washing of tex-

tiles laundered in the presence of avail-

able chlorine. Specimens subjected to

this test should show color change similar

to that produced by five home machine

launderings at 63 ± 3°C (145 ± 5°F) with

3.74 g per L (0.50 oz/gal) of 5% available

chlorine per 3.6 kg (8.0 lb) load.

9.7 Test No. 5A—This test is for eval-

uating the colorfastness to washing of

textiles that may be laundered in the pres-

ence of available chlorine. Specimens

subjected to this test should show color change similar to that produced by five home machine launderings at 49 ± 3°C (120 ± 5°F) with 200 ± 1 ppm available chlorine.

10. Report

10.1Report the test number.

10.2Report the grade number deter-mined for color change in 8.1 and the staining grade numbers for the evaluated fibers in the multifiber test fabric and/or bleached cotton test fabric as determined in 8.2.

10.3State which scale (Gray Scale for Staining or AATCC Chromatic Transfer-ence Scale) was used in evaluating stain-ing (see 12.13).

10.4Report the multifiber test fabric used and if bleached cotton test fabric was employed to avoid knit curling. 10.5Report the detergent used with color change and staining results (see 12.6 and 12.7).

10.6Report which laundering ma-chine is used.

11. Precision and Bias

11.1Precision and bias statements have been developed for Tests No. 2A and 5A. Although correlation work has been done, no precision and bias state-ments have been developed for Tests No. 1A, 3A and 4A.

11.1.1Because of changes in the deter-gents used in this method, these precision and bias statements may not apply to data or information obtained with the cur-rently available detergents.

11.2Test No. 2A.

11.2.1Summary. An interlaboratory test was carried out in May 1985 to estab-lish the precision of Test No. 2A. A part of the test was to determine if the wider 15 mm (0.6 in.) No. 10A multifiber test fabric could be substituted for the 8 mm (0.33 in.) wide No. 10. The complete test consisted of six laboratories evaluating 10 materials in duplicate by one operator using Test No. 2A.

11.2.2Color Change. Three raters from six laboratories independently eval-uated nine materials in duplicate using the Gray Scale for Color Change. The components of variance as standard devi-ations of the colorfastness grades (aver-ages of variances for No. 10 and No. 10A multifiber test fabrics) were calculated as follows:

Single-Operator

Component0.29

Within-Laboratory

Component0.29

Between-Laboratory

Component0.29

11.2.3Critical Differences. For the

components of variance reported in

11.2.2, two averages of observed values

should be considered significantly differ-

ent at the 95% probability level if the dif-

ference is equal to or exceeds the critical

differences shown in Table II.

11.2.4Staining. Three raters indepen-

dently rated the six fibers of the multifi-

ber test fabric (No. 10 and No. 10A) for

10 materials at six laboratories using the

Gray Scale for Staining. Of the 60 possi-

ble fiber/fabric combinations, only 51

could be used. The components of vari-

ance were averaged for the No. 10 and

No. 10A multifiber test fabrics and ap-

pear below as standard deviations of

staining ratings:

Single Operator

Component0.27

Within-Laboratory

Component0.34

Between-Laboratory

Component0.25

11.2.5Critical Differences. For the

components of variance reported in

11.2.4, two averages of observed values

should be considered significantly differ-

ent at the 95% probability level if the dif-

ference equals or exceeds the critical dif-

ferences shown in Table III.

11.2.6 Bias. Tests comparing five

home launderings at 40°C (105°F) with

one Launder-Ometer Test No. 2A indi-

cate there is no bias between the two

methods for the colorfastness and stain-

ing levels evaluated.

11.3Test No. 5A, Chlorine Bleach.

Table II—Critical Differences, Grades,

for the Condition Noted a

No. of

Observations

Single-

Operator

Precision

Within-

Lab

Precision

Between-

Lab

Precision

10.80 1.12 1.37

30.460.92 1.21

50.360.87 1.18

a Th e critical differences were calculated using t=

1.950 which is based on infinite degrees of freedom.

Table III—Critical Differences, Grades,

for the Condition Noted a

No. of

Observations

Single-

Operator

Precision

Within-

Lab

Precision

Between-

Lab

Precision

10.75 1.20 1.39

30.43 1.03 1.25

50.33 1.00 1.22

a Th e critical differences were calculated using t=

1.950 which is based on infinite degrees of freedom.

11.3.1Summary. An interlaboratory

test was carried out in 1984 to establish

the precision of Test No. 5A for deter-

mining the effect of chlorine bleach on

the colorfastness of fabrics. All speci-

mens were laundered in a Launder-

Ometer by one operator. Color change in

Test No. 5A was determined both visu-

ally and instrumentally. Details of the sta-

tistical analysis of the data can be found

in the report, Third Interlaboratory Study

of Proposed Launder-Ometer Test for

Colorfastness of Fabrics to Chlorine and

Non-Chlorine Bleaches, October 21,

1985, by J. W. Whitworth, Milliken Re-

search Corp., Spartanburg, SC.

11.3.2Visual Assessment. Four materi-

als were tested at each of five laborato-

ries. Three raters visually assessed the

color change of four specimens. The

components of variance as standard devi-

ations of colorfastness grades were calcu-

lated as follows:

Single Operator

Component0.38

Within-Laboratory

Component0.28

Between-Laboratory

Component0.27

11.3.3Critical Differences. For the

components of variance in 11.3.2, two

averages of observed values should be

considered significantly different at the

95% probability level if the difference

equals or exceeds the critical differences

shown in Table IV.

11.3.4Instrumental Assessment. Color

change as total color difference

(CIELAB) was measured on a spectro-

photometer or colorimeter using aper-

tures ranging in size from 13-51 mm

(0.5-2.0 in.) in diameter, illuminant D

65

/

10° observer or illuminant C/2° observer.

Six materials were tested at each of six

laboratories. One operator in each labora-

tory tested four specimens of each fabric.

The components of variance for ?E* ex-

pressed as coefficients of variation were

calculated to be:

Single-Operator

Component 6.8%

Between-Laboratory

Component11.2%

Table IV—Critical Differences, Grades,

for the Condition Noted a

No. of

Observations

Single-

Operator

Precision

Within-

Lab

Precision

Between-

Lab

Precision

1 1.03 1.29 1.49

30.590.98 1.23

50.460.91 1.17

a Th e critical differences were calculated using t=

1.950 which is based on infinite degrees of freedom.

11.3.5Critical Differences . For the components of variance reported in 11.3.4, two averages of observed values should be considered significantly differ-ent at the 95% probability level if the dif-ference equals or exceeds the critical dif-ferences shown in Table V .

11.3.6Bias . Tests comparing five home launderings at 49°C (120°F) with one Launder-Ometer Test No. 5A indi-cate there is no bias between the two methods for the colorfastness levels eval-uated (see 12.14).

12. Notes

12.1 For potential equipment information pertaining to this test method, please visit the online AATCC Buyer’s Guide at https://www.wendangku.net/doc/3816764301.html,/bg. AATCC provides the pos-sibility of listing equipment and materials sold by its Corporate members, but AATCC does not qualify, or in any way approve, endorse or certify that any of the listed equipment or materials meets the requirements in its test methods.

12.2Teflon is a registered trademark of the DuPont Co., Wilmington DE 19898.

Table V—Critical Differences, Percent of Grand Average for the Conditions Noted a,b

No. of Observations in Each Average

Single-Operator Precision

Between-Laboratory Precision

118.736.2310.832.85

8.432.1

a

Th e critical differences were calculated using t =1.950 which is based on infinite degrees of freedom.b

To convert th e values of th e critical differences to units of measure, multiply th e critical differences by th e average of th e two specific sets of data being compared and then divide by 100.

12.3The preheater/storage unit may be a side unit to the laundering machine or a sepa-rate module with its individual electric heater and thermostat to control water bath tempera-tures for heating containers and solutions prior to loading the laundering machine.

12.4Available from AATCC, P.O. Box 12215, Research Triangle Park NC 27709; tel:919/549-8141; fax: 919/549-8933; e-mail:orders@https://www.wendangku.net/doc/3816764301.html,; web site: https://www.wendangku.net/doc/3816764301.html,.12.5Bleached cotton test fabric in 32 × 32ends × picks/cm (80 × 80 ends × picks/in.)construction, 100 ± 3 g/m 2 and without fluo-rescent whitening agent should be used.

12.6The 1993 AATCC Standard Reference Detergent WOB (without fluorescent whiten-ing agent), a compact formulation, is the pri-mary detergent to be used in this test method.Where the effect of a fluorescent whitening agent is to be evaluated, 1993 AATCC Stan-dard Reference Detergent (with fluorescent whitening agent) should be used. Both deter-gents are available from AATCC, P.O. Box 12215, Research Triangle Park NC 27709; tel:919/549-8141; fax: 919/549-8933; e-mail:orders@https://www.wendangku.net/doc/3816764301.html,; web site: https://www.wendangku.net/doc/3816764301.html,.12.7The 2003 AATCC Standard Reference Liquid Detergent WOB (without fluorescent whitening agents) is a liquid detergent that has been approved as an alternate to the 1993AATCC Standard Reference Detergent WOB for Option 1B only at this time. The use of the Liquid Detergent in other test options is being studied. Both detergents are available from AATCC, P.O. Box 12215, Research Triangle Park NC 27709; tel: 919/549-8141; fax: 919/549-8933; e-mail: orders@https://www.wendangku.net/doc/3816764301.html,; web site:https://www.wendangku.net/doc/3816764301.html,.

12.8Use distilled water or deionized water of not more than 15 ppm hardness to dissolve the detergent and for the test solutions.

12.9Use sodium hypochlorite bleach pur-chased within the last six months for a stock solution.

12.9.1To confirm the stock solution’s hy-pochlorite activity, weigh 2.00 g liquid sodium hypochlorite into an Erlenmeyer flask and di-lute with 50 mL of deionized water. Add 10mL of 10% sulfuric acid and 10 mL of 10%potassium iodide. Titrate with 0.1N sodium thiosulfate until colorless.

Calculation:

% sodium hypochlorite

= The factor 0.03722 is derived by multiplying

the molecular weight of NaOCl (74.45 g/mol)by 0.001 (mL to L conversion) and dividing by 2 (mols of thiosulfate per hypochlorite).12.9.2Oxidizing power of sodium hy-pochlorite is typically expressed in terms of available chlorine, the equivalent amount of di-atomic chlorine present. A 5.25% NaOCl solu-tion contains 50,000 ppm available chlorine.12.10Crockmeter test cloth, 32 × 33 ends ×picks/cm (80 × 84 ends × picks/cm) combed cotton, desized, bleached (no fluorescent whit-ener or finishing material present) should be used.

12.11If staining evaluations are needed for Tests No. 4A and 5A, they may be carried out using the corresponding Tests No. 2A or 3A,which use no bleach. Test No. 2A is the no-bleach alternate for Test No. 5A, and Test No.3A is the no-bleach alternate for Test No.4A.

12.12If multifiber test fabric is used in con-junction with Tests 4A or 5A, the wool can ab-sorb the chlorine leaving very little for bleaching action. The wool may be removed from the multifiber test fabric before testing to eliminate this effect.

12.13For very critical evaluations and in cases of arbitration, grades must be based on the geometric Gray Scale for Staining.

12.14For additional information pertaining to the bias between Test No. 5A and five home washes, refer to Fig. 1 in Interlaboratory Study of Proposed Launder-Ometer Test for Colorfast-ness of Fabrics to Chlorine and Non-Chlorine Bleaches, Report to AA TCC Committee RA60,Colorfastness to Washing Test Methods,November 1984, New York NY by L. B.Farmer and J. W. Whitworth of Milliken Research Corp., Spartanburg SC, and J. G . Tew,AA TCC Technical Center, Research Triangle Park NC.

12.15AATCC Evaluation Procedure 7gives a method for computing Gray Scale grades from color measurement data.

mL Na 2S 2O 3()0.1N ()0.03722()

2.00 g NaOCl ()------------------------------------------------------------------------------100×

项目三色牢度测试要点

第一项耐摩擦色牢度的检测 1.采用标准 GB/T3920-2008《纺织品·色牢度试验·耐摩擦色牢度》。 GB 251-1995《评定沾色用灰色样卡》 GB 6151-1997《纺织品色牢度试验试验通则.》 2.测试仪器、用具 ⑴仪器设备: Y541B摩擦牢度试验仪、评定沾色用灰色样卡、电子 天平(0.01g)、烧杯、玻璃棒 ⑵染化药品:三级实验用水 ⑶实验材料:标准棉贴衬布(用于圆形摩擦头),待测试样(印花布、 纯棉布、牛仔布)。 3.试样准备: ⑴在标准大气条件下调湿 ⑵织物或地毯: ①尺寸50mmx240mm的试样,分别用于干摩擦试验和湿摩擦试验。 ②两经两纬。 (3)当测试试样有多种颜色的纺织品时,则使所有的颜色均被摩擦到。 如果颜色的面积足够大,可制备多个试样,对单个颜色分别评定。4.测试要点描述 以白布包在摩擦头上,规定压力为9±0.2N下10s内摩擦10次,往复动程104±3mm。 评定白布沾色情况(分干摩、湿摩)。

⑴评定时,在每个被评摩擦布的背面放置三层摩擦布。 ⑵在适宜的光源下,用评定沾色用灰色样卡评定摩擦布的沾色级数 ⑶湿摩擦:称量调湿后的摩擦布,将其完全浸入蒸馏水中,重新称量摩擦布以确保摩擦布的含水率达到95%~100%,然后进行操作。 第二项耐皂洗色牢度的检测 1.采用标准 GB/T 3921-2008《纺织品色牢度试验耐皂洗色牢度》 GB 250-1995《评定变色用灰色样卡》 GB 251-1995《评定沾色用灰色样卡》 GB 6151-1997《纺织品色牢度试验试验通则.》 GB 7546~7568 标准贴衬织物规格 GBll404 多纤维帖衬织物规格 2.测试仪器、用具 ⑴仪器设备:耐皂洗色牢度测试仪、评定变色用灰色样卡、评定沾色 用灰色样卡、电子天平(0.01g)、耐蚀不锈钢珠,直径约为6mm ⑵洗涤试液:(皂片中不应含有荧光剂) ①皂片 5 g/L 无水碳酸钠 2 g/L ②三级实验用水 ⑶实验材料:待测试样(印花布、纯棉布、涤纶布、涤棉毛混纺) 贴衬布(棉、腈纶、涤纶)

耐洗色牢度的检测方法

耐洗色牢度的检测方法(GB/T 3921.1-1997)(2006-09-02 12:21:39) 耐洗色牢度检测方法仅适于检测洗涤对纺织品色牢度的影响。耐洗色牢度由于配方、试验条件不同,有五种检测的方法。 ⒈检测准备 ⑴试样的制备:试样的制备方法有两种,具体如下: ①如试样是织物,取40mm×100mm的试样两块,一块正面与一块40mm×100mm多纤维贴衬织物相贴合,另一块夹于两块40mm×100mm单纤维贴衬织物之间。分别沿一短边缝合,制成两个组合试样。 ②如试样是纱线或散纤维,可将纱线编成织物,按织物试样制备。也可取纱线或散纤维制成一薄层,用量约为贴衬织物总量的一半。将一块试样夹于一块40mm×100mm多纤维贴衬织物和一块40mm×100mm染不上颜色的织物之间,另一块夹于两块40mm×100mm的单纤维贴衬织物之间,分别沿四边缝合,制成两个组合试样。 ⑵试剂: ①肥皂,含水率不超过5%,成分含量按干质量计,应符合下列要求: 游离碱(以Na2CO3计):0.3%(最大); 游离碱(以NaOH计):0.1%(最小); 总脂肪物:850g/kg(最小); 制备肥皂混合脂肪酸冻点:30℃(最高); 碘值:50(最大); 不含荧光增白剂。 ②皂液,每升水含5g肥皂和2g无水碳酸钠。 ③如需要,可用合成洗涤剂4g/L代替皂片5g/L。 ⑶检测用贴衬织物:检测用贴衬织物需两块,每块尺寸为40mm×100mm,第一块用试样的同类纤维制成,第二块则由表3-25规定的纤维制成。如试样是混纺或交织品,第一块为主要含量的纤维制成,第二块为次要纤维制成。 表3-25 耐洗色牢度试验用贴衬织物 第一块 贴衬织物第二块贴衬织物 方法1、2、3 方法4 方法5 棉纤维羊毛粘胶纤维粘胶纤维 羊毛棉纤维-- 丝棉纤维棉纤维- 亚麻棉纤维棉纤维或粘胶纤维棉纤维或粘胶纤维 粘胶纤维羊毛棉纤维棉纤维 醋酯纤维粘胶纤维粘胶纤维- 聚酰胺纤维羊毛或粘胶纤维棉纤维或粘胶纤维棉纤维或粘胶纤维 聚酯纤维羊毛或棉纤维棉纤维或粘胶纤维棉纤维或粘胶纤维

色牢度测试标准

色牢度测试标准:

1. 《纱线捻度测试》 GB/T 2543.1-2001;GB/T 2543.2-2001;ISO 2061:1995; ISO 7211-4:1984;BS EN ISO 2061:1996; ASTM D1422-1999;ASTM D1423-2002; 2. 《织物单位面积重量的测定》 GB/T 4669-1995;FZ/T 60003-1993;ISO 3801:1977; ISO 9037-1:1989;JIS L 1096-1999 Section 6.4; BS 2471-2005 ;ASTM D 3776-2002; ASTM D 3887-2004 Section 9; 3. 《纺织品耐水洗色牢度测试》 GB/T 3921. 1~5-1997;GB/T 12490-1990;ISO 105 C01-C05:1989; ISO 105-C10:2006;ISO 105-C06:2002;DIN EN ISO 105-C06:1997; AATCC 61-2003;JIS L 0844-2005(Method B Method C); 4. 《纺织品耐摩擦色牢度测试》 GB/T 3920-1997;ISO 105-X12:2001;BS EN ISO 105-X12:2002; DIN EN ISO 105-X12:2002;EN ISO 105-X12: 2002; AATCC 8-2005;JIS L 0849-2004: Type I; 5. 《纺织品耐汗渍色牢度测试》 GB/T 3922-1995;ISO 105-E04:2002;BS EN ISO 105-E04:1996; DIN EN ISO 105-E04:1996;AATCC 15-2002 6. 《纺织品耐水渍色牢度测试》 GB/T 5713-1997;ISO 105-E01:2002;BS EN ISO 105-E01:1996; DIN EN ISO 105-E01:1996;EN ISO 105-E01:1996; AATCC 107-2002 7. 《纺织品耐海水色牢度测试》 GB/T 5714-1997;ISO 105-E02:2002;BS EN ISO 105-E02:1996; DIN EN ISO 105-E02:1996;EN ISO 105-E02:1996; JIS L 0847-2004;AATCC 106-2002 8. 《纺织品耐干洗色牢度测试》

耐水洗色牢度

染色牢度(简称色牢度),是指染色织物在使用或加工过程中,经受外部因素(挤压、摩擦、水洗、雨淋、曝晒、光照、海水浸渍、唾液浸渍、水渍、汗渍等等)作用下的退色程度,是织物的一项重要指标。根据试样的变色和未染色贴衬织物的沾色来评定牢度等级。纺织品色牢度测试是纺织品内在质量测试中一项常规检测项目。色牢度好与差,直接涉及人体的健康安全,色牢度差的产品在穿着过程中,碰到雨水、汗水就会造成面料上的颜料脱落褪色,则其中染料的分子和重金属离子等都有可能通过皮肤被人体吸收而危害人体皮肤的健康,另一方面还会影响穿在身上的其它服装被沾色,或者与其他衣物洗涤时染脏其他衣物。因织物在加工和使用过程中所受的条件差别很大,要求各不相同,故现行的试验方法大部分都是按作用的环境及条件进行模拟试验或综合试验,所以染色牢度的试验方法内容相当广泛。 但纵观国际标准组织(ISO)、美国染色家和化学家协会(AATCC)、日本(JIS)、英国(BS)等诸多标准,最常用的还是耐洗、耐光、耐摩擦及耐汗渍、耐熨烫、耐气候等项。而在实际工作中,主要是根据产品的最终用途及产品标准来确定检测项目,如毛纺织产品标准中规定必须检测耐日晒色牢度,针织内衣当然要测耐汗渍牢度,而户外用纺织品(如遮阳伞、灯箱布、蓬盖材料)则当然要检测其耐气候色牢度。 常见的单项色牢度测 试有耐洗色牢度、耐汗渍色牢度、耐摩擦色牢度等 1 色牢度标准 纺织品色牢度测试采用的GB/T标准与AATCC标准见表1。 表1色牢度标准 Tab.1 The Standards of Color Fastness 项目 GB/T标准 AATCC标准 耐水色牢度 GB/T 5713—1997[2] AATCC 107—2007[3] 耐汗渍色牢度 GB/T 3922—1995[4] AATCC 15—2007[5] 耐摩擦色牢度 GB/T 3920—2008[6] AATCC 8—2007[7] 2 耐水色牢度标准比较 2.1 试样 G B / T 5 7 1 3—1 9 9 7规定的试样尺寸为4 0 m m×1 0 0 m m,为长方形试样,一般掌握试样纬向长度40 mm,经向长度100 mm。AATCC 107—2007规定的试样尺寸为(60±2)mm×(60±2) mm,为正方形试样。 2.2 贴衬织物 GB/T 5713—1997规定的贴衬可以是多纤维贴衬织物,也可以是单纤维贴衬织物。若使用单纤维贴衬,则其中一块贴衬用试样的同类纤维制成,另一块贴衬用相应标准规定的纤维制成,如试样为混纺或交织品,则第一块用主要含量的纤维制成,第二块用次要含量的纤维制成。多纤维贴衬规格有两种,DW型及TV型:DW型组成为羊毛、腈纶、涤纶、锦纶、棉、醋酯;TV型组成为粘胶、腈纶、涤纶、锦纶、棉、三醋酯。AATCC 107—2007规定只能使用多纤维贴衬,有NO.1及NO.10两种规格。NO.1组成为羊毛、粘胶、桑蚕丝、锦纶、棉、醋酯;NO.10组成为羊毛、腈纶、涤纶、锦纶、棉、醋酯。

AATCC 61-2007 耐洗色牢度

Developed in 1950 by AATCC Committee RA60; revised 1952, 1954, 1957, 1960, 1961, 1970, 1972, 1986 (title change), 1989, 1993, 1994, 1996, 2003, 2006 (title change), 2007; reaffirmed 1956, 1962, 1965, 1968, 1969, 1975, 1980, 1985; editorially revised 1973, 1974, 1975, 1976, 1981, 1983, 1984, 1991, 1995, 1998, 2002, 2004; editorially re-vised and reaffirmed 2001. Partly equivalent to ISO 105-C06. 1.Purpose and Scope 1.1These accelerated laundering tests are to evaluate the colorfastness to laun-dering of textiles which are expected to withstand frequent laundering. The fabric color loss and surface changes resulting from detergent solution and abrasive ac-tion of five typical hand or home launder-ings, with or without chlorine, are roughly approximated by one 45 min test (see 9.2-9.6). However, the staining ef-fect produced by five typical hand or home launderings cannot always be pre-dicted by the 45min test. Staining is a function of the ratio of colored to undyed fabrics, fiber content of fabrics in the wash load and other end-use conditions which are not always predictable. 1.2 When this test method was origi-nally developed, various options of this method were intended to evaluate the color change and staining by five home or commercial launderings, on an accel-erated basis. Throughout the years, com-mercial laundering procedures have changed and commercial cleaning today involves many different types of pro-cesses, dependent on the type of product being cleaned that cannot be duplicated by one accelerated laboratory procedure. In 2005, all references to commercial laundering were removed as it is not known if these procedures accurately rep-licate typical commercial laundering pro-cesses used today. 2. Principle 2.1Specimens are tested under appro-priate conditions of temperature, deter-gent solution, bleaching and abrasive ac-tion such that the color change is similar to that occurring in five hand or home launderings. The color change is obtained in a conveniently short time. The abra-sive action is a result of the frictional ef-fects of fabric against canister, the low li-quor ratio and the impact of the steel balls on the fabric. 3. Terminology 3.1colorfastness, n.—the resistance of a material to change in any of its color characteristics, to transfer of its color- ant(s) to adjacent materials or both, as a result of the exposure of the material to any environment that might be encoun- tered during the processing, testing, stor- age or use of the material. 3.2laundering, n.—of textile mate- rials, a process intended to remove soils and/or stains by treatment (washing) with an aqueous detergent solution and nor- mally including subsequent rinsing, ex- tracting and drying. 4. Safety Precautions NOTE: These safety precautions are for information purposes only. The pre- cautions are ancillary to the testing proce- dures and are not intended to be all inclu- sive. It is the user’s responsibility to use safe and proper techniques in handling materials in the test method. Manufactur- ers MUST be consulted for specific de- tails such as material safety data sheets and other manufacturer’s recommenda- tions. All OSHA standards and rules must also be consulted and followed. 4.1Good laboratory practices should be followed. Wear safety glasses in all laboratory areas. 4.2All chemicals should be handled with care. 4.3The 1993 AATCC Standard Refer- ence Detergent WOB may cause irrita- tion. Care should be taken to prevent ex- posure to skin and eyes. 4.4An eyewash/safety shower should be located nearby for emergency use. 4.5Manufacturer’s safety recommen- dations should be followed when operat- ing laboratory testing equipment. 5. Apparatus, Reagents and Materials 5.1Launder-Ometer or other compara- ble equipment (see 12.1). 5.1.1A laundering machine for rotat- ing closed canisters in a thermostatically controlled water bath at 40 ± 2 rpm (see 12.1). 5.1.2Stainless steel lever lock canis- ters Type 1 (see 12.1) 500 mL (1 pt), 75 × 125 mm (3.0 × 5.0 in.) for Test No. 1A. 5.1.3Stainless steel lever lock canis- ters Type 2 (see 12.1) 1200 mL, 90 × 200 mm (3.5 × 8.0 in.) for Tests No. 2A, 3A, 4A and 5A. 5.1.4Adapter plates for holding canis- ters (see 5.1.3) on laundering machine shaft (see 12.1). 5.1.5Stainless steel balls, 6 mm (0.25 in.) in diameter (see 12.1). 5.1.6Teflon fluorocarbon gaskets (see 7.4.2, 12.1 and 12.2). 5.1.7Preheater/storage module (see 7.4, 12.1 and 12.3). 5.2Scales for rating test results. 5.2.1AA TCC Chromatic Transference Scale (see 12.4). 5.2.2Gray Scale for Color Change (see 12.4). 5.2.3Gray Scale for Staining (see 12.4). 5.3Reagents and materials. 5.3.1Multifiber test fabrics No. 1 and FB (8 mm [0.33 in.] bands) contains bands of acetate, cotton, nylon, silk, vis- cose rayon and wool. Multifiber test fab- rics No. 10, and FA (8 mm [0.33 in.] bands) and No. 10A and FAA (15 mm [0.6 in.] bands) contain bands of acetate, cotton, nylon, polyester, acrylic and wool (see 12.5). 5.3.2 Bleached cotton test fabric, 32 × 32 ends × picks/cm (80 × 80 ends × picks/in.) construction, 100 ± 3 g/m2 (3.0 ± 0.1 oz/yd2), desized without fluorescent whitening agent (see 12.5). 5.3.31993 AATCC Standard Refer- ence Detergent WOB (without fluores- cent whitening agent and without phos- phate) (see 10.5 and 12.6). 5.3.41993 AATCC Standard Refer- ence Detergent (with fluorescent whiten- ing agent) (see 10.5 and 12.6). 5.3.5Water, distilled or deionized (see 12.7). 5.3.6Sodium hypochlorite (NaOCl) bleach (see 12.8). 5.3.7Sodium carbonate (Na 2 CO 3 ). 5.3.8Sulfuric acid (H 2 SO 4 ), 10% (see 12.8.1). 5.3.9Potassium iodide (KI), 10% (see 12.8.1). 5.3.10Sodium thiosulfate (Na 2 S 2 O 3 ), 0.1N (see 12.8.1). 5.3.11Crockmeter test cloth cut in 50 mm (2 in.) squares (see 12.9). 5.3.12White cards (specimen mounts) with Y tristimulus value at least 85%. 6. Test Specimens 6.1The sizes of the specimens required for the various tests are as follows: 50 × 100 mm (2.0 × 4.0 in.) for Test No. 1A, 50 × 150 mm (2.0 × 6.0 in.) for Tests No. 2A, 3A, 4A and 5A. 6.2Test only one specimen in each canister. 6.2.1Test one specimen per laboratory sample. Replication may be advisable for AATCC Test Method 61-2007 Colorfastness to Laundering: Accelerated

欧盟关于色牢度的标准

欧盟关于色牢度的标准 耐洗涤色牢度Color fastness to Laundry. 耐洗涤色牢度,变色至少应3~4级,沾色(Staining)至少应3~4级。 本规范不适用于标签标明“仅干洗”或者类似产品(对于此类标志的产品,其范围与正常实际使用情况相同)、白色产品、不染色印花的产品、不可洗涤的家具织物。 评估与检定:申请者提交使用方法ISO 105 C06(单洗,以产品上标注的温度,使用过硼酸盐洗涤剂)试验的试验报告。 耐汗渍色牢度(酸汗和碱汗) Color fastness to acid perspiration / alkali perspiration 耐汗渍色牢度(酸汗和碱汗)至少应3~4级(变色和沾色)。 但是,对于深色织物(标准深度>1/1)以及由再生羊毛制成,或者组成成分中含有超过20%的蚕丝的织物,也允许3级。 本规范不适用于白色产品、不染色印花的产品、家具织物、窗帘或用于室内装饰的类似纺织品。 评估与检定:申请者提交使用方法ISO 105 E04(酸汗和碱汗,与多纤维贴衬织物对照)试验的试验报告。 耐湿摩擦色牢度Color fastness to wet crocking/ Rubbing. 耐湿摩擦色牢度至少应2~3级。但是对于用靛蓝染料染色的粗斜纹棉布(牛仔布),也允许2级。 本规范不适用于白色产品、不染色印花的产品。 评估与检定:申请者需提交使用方法ISO 105 X12试验的试验报告。 耐干摩擦色牢度Color fastness to dry crocking/ Rubbing.. 耐干摩擦色牢度至少应4级。 但是,对于用靛蓝染料染色的粗斜纹棉布(牛仔布),也允许3-4级。 本规范不适用于白色产品、不染色印花的产品,和用于室内装饰的窗帘或类似纺织品。 评估与检定:申请者提交使用方法ISO 105 X12试验的试验报告。 耐光色牢度Color fastness to light 家具、窗帘或帷幔用织物,耐光色牢度至少应5级;其他产品耐光色牢度至少4级。 但是,家具、窗帘或帷幔用织物的颜色较浅(标准深度<1/12)时,以及组成成分中有超过20%的羊毛,或角蛋白纤维,或蚕丝,或亚麻,或其他韧皮纤维时,也允许4级。 本要求不适用于床垫套、床垫防护物或内衣。 评估与检定:申请者需提交使用方法ISO 105 B02试验的试验报告

阿迪达斯耐洗色牢度

目的 这种测试方法可以用来评定各种纺织品的耐水洗色牢度。 这种测试方法也可以用来测定同一织物上不同明暗颜色之间的串色程度,而且当一块儿织物含有明暗不同的多种颜色时,必须进行该项测试。 原理 ⅰ)将纺织品试样与DW ISO 105-F10多纤维贴衬织物合在一起,放于皂液中,在规定的时间和温度下进行搅拌。为了增加摩擦作用,可以在皂液中放一些小钢球。用相应的灰色样卡评定试样的变色和多纤维贴衬织物的沾色。 ⅱ)将明暗多色织物放于皂液中,在规定的时间和温度下进行搅拌。为了增加摩擦作用,可以在皂液中放一些小钢球。用相应的灰色样卡评定试样的变色和多纤维贴衬织物的沾色。 设备 合适的机械装置,在可以调温的水浴锅中心装有一根旋转轴杆,盛有多只不锈钢容器,转速为40±2 r/min。 不锈钢容器的大小为:直径7.5㎝,高度为12.5㎝,容量为550±50ml 不锈钢球,防腐蚀,直径大约为0.6㎝,重为1公斤 符合ISO-F10标准的的DW多纤维粘衬织物 250ml的塑料量筒 250ml的烧杯 移液吸管 2公升塑料或者玻璃杯 温度计(0~100℃) 数字计时器 阿迪达斯集团专有和机密信息: 本手册包含专有和机密信息,仅限于阿迪达斯集团和其授权的供应商、分包商以及材料供应商使用。本手册的收件人必须遵守使用要求,不得向除需要使用该信息的本公司员工以外的任何人透露本手册包含的任何信息。

平缝机 白色缝纫线 变色评定灰色样卡 沾色评定灰色样卡 对色灯箱 试剂 符合ECE要求的磷酸盐B型洗涤剂(不添加荧光增白剂) 或符合AATCC标准的WOB型洗涤剂(不添加荧光增白剂) 蒸馏水/去离子水,三级 试样准备 织物: 类型(ⅰ)剪取长×宽=10㎝×4㎝的测试布样,对于彩色织物,印花布或者条纹布,要根据织物颜色的种类设计多组试验,试样的留边不能超过5㎝。 剪取多纤维贴衬织物长×宽=10㎝×4㎝ 将测试试样与一块多纤维贴衬织物相贴合,用缝纫线沿短边进行缝合形成 组合试样。 类型(ⅱ)剪取两块儿长×宽=10㎝×4㎝的测试试样,一块儿为深色的布样,另一块儿为浅色的布样。 浅色织物和深色织物的重量和结构要相同(如果达不到这种要求的话应使 它们的纤维成分保持相同) 将测试试样用缝纫线沿短边进行缝合形成组合试样。 颜色的阿迪达斯集团专有和机密信息: 本手册包含专有和机密信息,仅限于阿迪达斯集团和其授权的供应商、分包商以及材料供应商使用。本手册的收件人必须遵守使用要求,不得向除需要使用该信息的本公司员工以外的任何人透露本手册包含的任何信息。

纺织品色牢度的测试方法

纺织品色牢度的测试方法 摘 要:介绍了纺织品色牢度中变色灰色样卡、沾色蓝色样卡的使用方法,以及色牢度仪器评定的方法。 纺织品色牢度测试主要分为两种:色牢度目测评定和色牢度仪器评定。 1、色牢度目测评定 色牢度目测评定是以试后样与原样两者之间以目测对比色差的大小为依据的。通常采用变色和沾色灰色样卡,以及蓝色羊毛标作为评定标准。 1.1 评定变色用灰色样卡 由五对无光的灰色小卡片(或布片)组成,分为五个牢度等级,即5,4,3,2,1,在没两个等级中再补充半级,即4-5,3-4,2-3,1-2,合称五级九档灰卡。每对的第一组均是中性灰色,其中仅5级的第二组成相一致,其他各对的第二组成在色泽上依次变浅,色差逐级增大。 GB 250 评定变色用灰色样卡 本灰卡适用于GB 、 ISO 、AATCC 、DIN 、BS 、JIS 、 EN 标准中的纺织品色牢度评级

变色评级时,将原样与试后样按同一组织结构方向并列置于同一平面上,灰色样卡也置于其旁,然后在上面放一个中性灰色遮框,使灰色样卡与试样面积相同,在规定观察条件下,以样卡色差程度与试样相近的一级作为试样牢度等级。 1.2 评定沾色用灰色样卡 沾色灰卡由五对无光的灰色或白色小卡片(或布片)组成,同样分为五级九档。每对的第一组成均是白色,其中仅五级的第二组成相一致,其他各对的第二组成依次变深,色差逐级增大。 GB 251评定沾色用灰色样卡 本灰卡适用于GB 、ISO 、AATCC 、DIN 、BS 、JIS 、EN 标准中的纺织品色牢度评级 变色评级示意图 1-灰卡 2-原样 3- 灰卡中的一对纸片4- 试 沾色评级示意图 1-沾色灰卡 2-相邻的两对小纸片 3-试前贴衬 4-试后

色牢度测试标准

色牢度测试标准

色牢度测试标准:

1. 《纱线捻度测试》 GB/T 2543.1-2001;GB/T 2543.2-2001;ISO 2061:1995; ISO 7211-4:1984;BS EN ISO 2061:1996; ASTM D1422-1999;ASTM D1423-2002; 2. 《织物单位面积重量的测定》 GB/T 4669-1995;FZ/T 60003-1993;ISO 3801:1977; ISO 9037-1:1989;JIS L 1096-1999 Section 6.4; BS 2471-2005 ;ASTM D 3776-2002;

ASTM D 3887-2004 Section 9; 3. 《纺织品耐水洗色牢度测试》 GB/T 3921. 1~5-1997;GB/T 12490-1990;ISO 105 C01-C05:1989; ISO 105-C10:2006;ISO 105-C06:2002;DIN EN ISO 105-C06:1997; AATCC 61-2003;JIS L 0844-2005(Method B Method C); 4. 《纺织品耐摩擦色牢度测试》 GB/T 3920-1997;ISO 105-X12:2001;BS EN ISO 105-X12:2002; DIN EN ISO 105-X12:2002;EN ISO 105-X12: 2002; AATCC 8-2005;JIS L 0849-2004: Type I; 5. 《纺织品耐汗渍色牢度测试》 GB/T 3922-1995;ISO 105-E04:2002;BS EN ISO 105-E04:1996; DIN EN ISO 105-E04:1996;AATCC 15-2002 6. 《纺织品耐水渍色牢度测试》 GB/T 5713-1997;ISO 105-E01:2002;BS EN ISO 105-E01:1996; DIN EN ISO 105-E01:1996;EN ISO 105-E01:1996; AATCC 107-2002 7. 《纺织品耐海水色牢度测试》 GB/T 5714-1997;ISO 105-E02:2002;BS EN ISO 105-E02:1996; DIN EN ISO 105-E02:1996;EN ISO 105-E02:1996; JIS L 0847-2004;AATCC 106-2002 8. 《纺织品耐干洗色牢度测试》 GB/T 5711-1997;ISO 105-D01:1993;BS EN ISO 105-D01:1995; DIN EN ISO 105-D01:1995;EN ISO 105-D01:1995; AATCC 132-2004; 9. 《纺织品耐热压色牢度测试》 GB/T 6152-1997;ISO 105-X11:1994;EN ISO 105-X11:1996; DIN EN ISO 105-X11:1996;BS EN ISO 105-X11:1996 AATCC 133-2004 10. 《纺织品耐干热(热压除外)色牢度测试》

影响纺织品色牢度的几个因素.

纺织品的染色牢度(简称色牢度,是指染色或印花的织物在使用或加工过程中,经受外部因素(挤压、摩擦、水洗、雨淋、曝晒、光照、海水浸渍、唾液浸渍、水渍、汗渍等等作用下的退色程度,是织物的一项重要指标。色牢度好,纺织品在后加工或使用过程中不容易掉色;色牢度差,则会出现掉色或沾色等情况, 造成很多麻烦。 1 纺织品色牢度的常见问题 在日常抽检和消费者投诉中,最常见的纺织品色牢度问题有以下几方面: 1耐日晒牢度不合格。外套服装在穿着过程中,受日光照射多的部位颜色变浅或变色(一般是后背和肩膀部位,而照射不到或照射少的地方颜色不变或变化轻,造成原来颜色一致的产品颜色深浅不一,无法再继续使用。 2耐水洗色牢度、耐皂洗色牢度和耐干洗色牢度不合格。高级的蚕丝服装、羊毛服装、纯棉服装最容易存在这方面问题。 3耐摩擦色牢度不合格。纺织品在使用过程中,因为产品的不同部位受到的摩擦程度不同,掉色的程度不同。比如上衣、袖子的肘部、领部及腋下最容易掉色。此外,裤子的臀部和膝盖部位也容易掉色。 4汗渍色牢度不合格。主要是夏天的衣服或贴身的内衣在穿着时,经汗液的浸渍而掉色。 2 影响色牢度的因素和改善方法 色牢度差的产品在穿着过程退色,会影响穿在身上的其他服装,或者在与其他衣物洗涤时沾染其他衣物,影响美观和服用性能;另一方面,色牢度好与坏还直接关系到人体的健康安全。色牢度差的产品上的染料分子和重金属离子等有可能通过皮肤被人体吸收而危害皮肤,甚至伤害身体健康。 影响纺织品色牢度的因素分内部因素和外部因素。内部因素指染料和纤维结合的牢固程度,外部因素指产品在使用过程中外界因素对其施加的外力或提供的环

境条件。外部因素无法控制,因而生产者要努力提高产品本身的色牢度。下面就个人实际经验提出几个解决办法,供大家借鉴。 2.1 染化料的选择 一种产品的色牢度如何,染化料的选择非常重要。如果染化料选择不合适,再好的助剂、再好的染色工艺, 都没有办法染出高质量的色牢度。只有选择了合适的染料,才能谈及下一步问题。 2.1.1 根据纤维的特性选择染料 不同种类染料与纤维的结合形式不同,结合键的牢固程度也不同。在染料种类确定了以后,再选择染色性能高的染料。比如,染羊毛织物时,同样是强酸性染料,国产的就不如进口的强酸性染料染色性能好,不仅色泽不好, 其结合的牢固程度也不如后者好;或者同样是国产强酸性染料,不同的染料与羊毛结合牢度及染色鲜艳度也不同。如用弱酸染料染羊毛纱的色牢度就比强酸性染料高;而纯棉织物或再生纤维素纤维类织物,则既可以用直接染料, 也可以用活性染料;蚕丝类织物除可以用弱酸性染料、某些活性染料外,还可用个别直接染料。 2.1.2 根据颜色深浅选染料 在确定了染料的大类以后,就要根据所染颜色的色系和深度进一步确定具体使用哪种染料。第一,尽量选用色光与所需颜色接近的染料,如有偏差,再用别的染料调色。第二,看所选染料自身的色牢度指标。染料自身色牢度就差,通过工艺最多可提高半级色牢度。第三,看染料上染的饱和度能否达到所要求颜色的深度。如果选上染率很低的染料,即使经过加工能临时达到所需要的高深 科技·前沿 Science & Front 影响纺织品色牢度的几个因素 Several Factors to Effect Textile Color Fastness

耐汗渍色牢度测试的基本知识和操作流程

耐汗渍色牢度测试的基本知识和操作流程 1、测试的目的和原理 1.1 目的:测试颜色纺织品上的染料或印花对汗液的抵抗性 1.2 原理:将附有标准多纤布的试样浸于人造汗液中,然后在规定的压力和温度条件下压放于耐汗色牢度测试仪内一 段时间,然后将试样和多纤布隔开晾干,再用标准灰尺对试样的色变和多纤布的沾色进行评级。 2、参考测试方法 2.1 ISO 105 E04 :1994 / BS EN ISO 105 E04 :1996 3、设备和材料 3.1 AATCC 耐汗渍色牢度测试仪 3.2 21块尺寸为60mmx115mmx1.5mm的塑料板 3.3 烘箱(37+2°C) 3.4 SDC或1号标准多纤布 3.5 蒸馏水或去离子水 3.6 ISO/BS 标准褪色灰尺和沾色灰尺各一把。 3.7 标准光源 3.8 氯化钠(NaCl)

3.9 单盐酸基组氨酸(CH9O2N3HCl.H2O) 3.10 磷酸氢二钠:2结晶水(Na2HPO 4.2H2O) 3.11 磷酸二氢钠:2结晶水(NaH2PO 4.2H2O) 3.12 氢氧化钠(NaOH) 3.13 容量瓶500ml,100ml 3.14 滴瓶50ml 3.15 棕色细口瓶装1000ml 3.16 电子磅 4、试样的准备。 4.1 剪取尺寸为40mm100mm的试样和多纤布,并沿试样和多纤布的一条短边将试样和多纤布面对面车缝在一起。 5、试剂的配制。 5.1 0.1N的氢氧化钠溶液的配制 将2g的氢氧化钠溶于500ml的蒸馏水或去离子水中,配置成浓度为0.1N的氢氧化钠溶液 5.2 碱性汗液 将0.5g单盐酸基组氨酸(1结晶水),5g氯化钠,2.5g磷酸氢二钠(2结晶水)溶于1L 的蒸馏水或去离子水中,然后用0.1N的氢氧化钠溶液调至PH8.0 5.3 酸性汗液 将0.5g单盐酸基组氨酸(1结晶水),5g氯化钠,2.2g磷酸二氢钠(2结晶水)溶于1L

AATCC61:2013美国水洗色牢度中文翻译

耐水洗色牢度:加速法 1.目的与范围 2.1.1本加速洗涤测试方法,用于评价纺织品经频繁洗涤后的水洗色牢度,织物经五次经典的手洗或家庭洗涤的洗涤剂溶液和摩擦作用所引起的褪色及表面变化,接近于一次45分钟的试验。然而,五次经典的手洗或家庭洗涤所造成的沾染程度,并不能通过 1.2 2.原理 2.1 结果。 3.术语 3.1 3.2洗涤——对纺织材料,通过水溶液洗涤剂洗涤并清洗、脱水和干燥,以洗去污渍的过程。 4.安全措施 注:这些安全措施仅作为信息提供。作为测试过程的辅助措施,安全正确地进行实验操作是操作者的责任。生产商必须对安全细节如安全数据表及其他生产商的推荐进行指导。必须参考和遵守所有的OSHA标准和规定。?

4.1遵循良好的实验室管理规范,在实验室区域佩带护目镜。? 4.2所有化学品必须小心轻放。? 4.3?AATCC1993标准洗涤剂AATCC2003标准洗涤剂可致敏,需注意不可碰到眼睛和皮肤。? 4.4?应就近装备洗眼器/安全冲淋设施以备急用。? 4.5?当操作仪器时,应参照仪器生产商的安全说明。 5.设备及物料 5.1 5.1.1 40± 用于 5.1.4 5.1.5 5.1.6 5.1.7 5.1.8 5.2 5.2.2AATCC变色灰卡(AATCC评价程序1) 5.2.3AATCC沾色灰卡(AATCC评价程序2) 5.3试剂和材料 5.3.1标准多纤维织物NO.1包括醋酯,棉,尼龙,真丝,粘胶,羊毛。1标准多纤维织物NO.10包括醋酯,棉,尼龙,涤纶,腈纶,羊毛。 5.3.2组织为经纬80x80/inch、布重为100±3g/sq.m(3.0±0.1oz/sq.yd)的测试用

常用纺织品色牢度的检测方法归纳

常用纺织品色牢度的检测方法归纳 摘要:详细介绍了纺织品耐洗色牢度、耐光色牢度、耐气候色牢度、耐汗渍色牢度、耐摩擦色牢度和耐唾液色牢度的测试原理和具体方法。 1、纺织品耐洗色牢度检测 原理:将试样与一块或两块规定的贴衬织物贴合,放于盛有洗涤液的容器中,在规定的时间和温度下,经机械回转搅拌,然后冲洗干燥,用灰色样卡评定试样的变色和贴衬织物的沾色情况。 试样准备:剪取一块或两块尺寸为40mm×100mm的试样,试样应包含样品中所有颜色。试样夹于贴衬织物之间,沿短边缝合,形成组合试样。 试剂: 试剂一:皂片,含水率不超过5%; 试剂二:合成洗涤剂,无水碳酸钠(化学纯)。 贴衬织物:需两块,第一块用试样的同种纤维制成,第二块由下表所规定的纤维制成。如试样是混纺或交织物,则第一块为主要含量的纤维制成,第二块为次要含量的纤维制成。

试验步骤:启动试验机(如下图),经规定时间后取出组合试样,用冷三级水清洗两次,然后再流动冷水中冲洗10min,挤去水分,展开组合试样,悬挂在60℃一下的空气中干燥。 结果评定:在标准光源下,分别用评定变色用,沾色用灰色样卡评定试样的变色和贴衬织物的沾色。 适用标准:GB/T 3921.1-3921.5,ISO 105 C01-C05,AATCC 61。 耐洗色牢度试验机 2、纺织品耐光色牢度检测 原理:将供试验的染色织物和标准色同时在日光灯光线下曝晒,然后将试样的褪色程度与色样的褪色程度进行对比,得出评价。 方法:在通常的试验中,其照射光源是以日光为基础,但日光照射的试验周期长,使用不便,故实际中多采用人工光源。按光源主要分为两种:日光法和氙弧等试验仪法。 2.1日光法:试样与八个蓝色羊毛标准同时在不受雨淋的规定条件下进行日光曝晒,一段时间后,将试样与八个蓝色羊毛标准进行对比,评定耐光色牢度。 试验设备:曝晒架,并盖以玻璃窗。 试样尺寸:织物不小于60mm×10mm,紧赋予硬卡上。

- 影响纺织品色牢度的几个因素.

- 各种色牢度

- AATCC美国水洗色牢度中文翻译

- AATCC61:2013美国水洗色牢度中文翻译

- 水洗色牢度如何测试

- 织物水洗色牢度测试的意义

- 各类标准水洗色牢度的测试方法

- AATCC61:2013美国水洗色牢度中文翻译

- 各类标准水洗色牢度的测试方法

- 测试与标准:耐洗色牢度

- 欧盟关于色牢度的标准

- 色牢度标准

- AATCC61-水洗色牢度

- 水洗及色牢度测试报告GZSL1205046186TX(1)

- 纺织品色牢度常见问题及解决方法

- 国内外三种耐水洗色牢度方法的要求

- AATCC61:2013美国水洗色牢度中文翻译

- 纺织品色牢度常见问题及解决方法

- 纺织品色牢度常见问题及解决办法

- 耐水洗色牢度