1.2379 X153CrMoV12-1

1.2379 X153CrMoV12

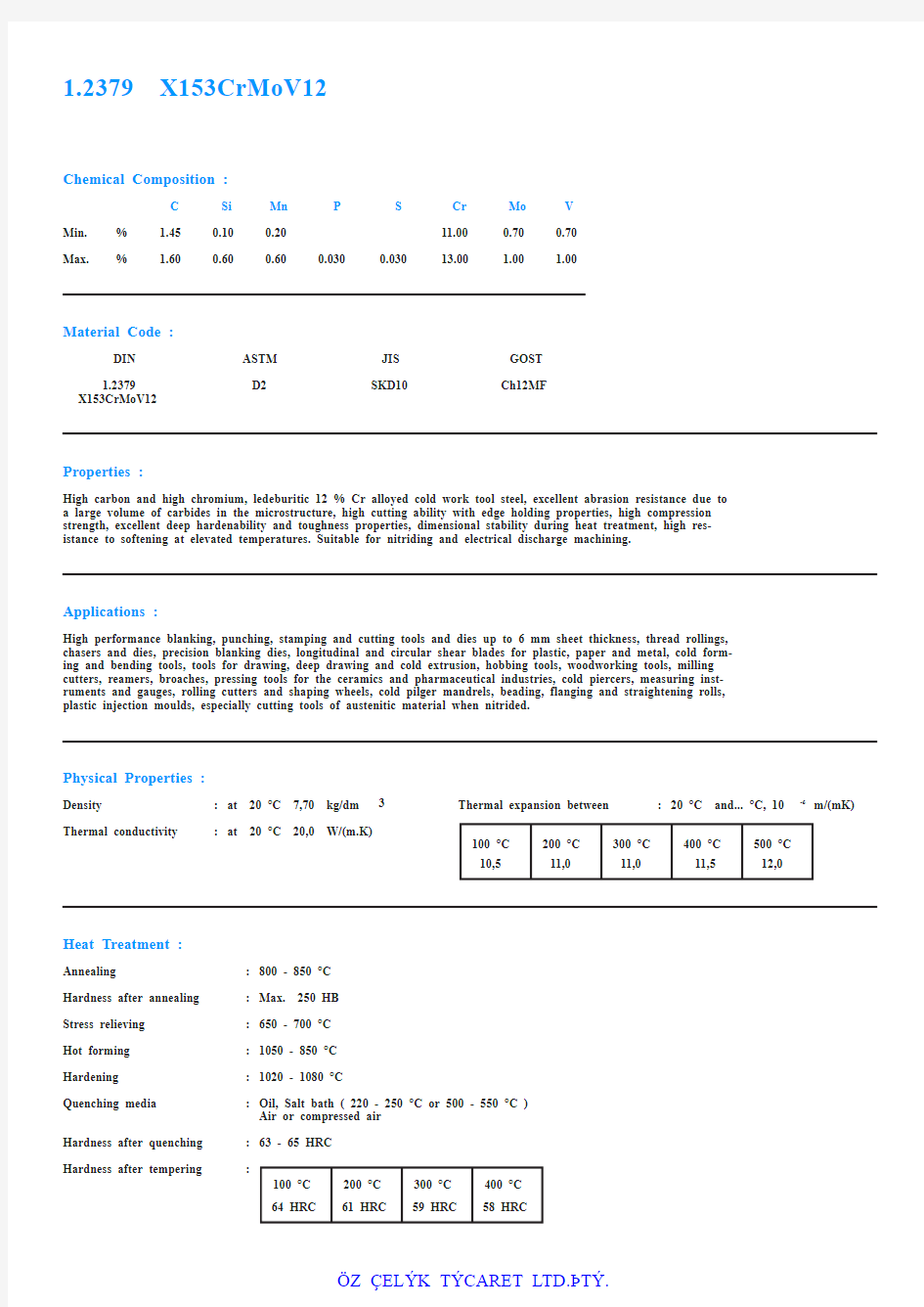

Chemical Composition :

C Si Mn P S Cr Mo V

Min.% 1.450.100.2011.000.700.70

Max.% 1.600.600.600.0300.03013.00 1.00 1.00

Material Code :

DIN ASTM JIS GOST

1.2379D2SKD10Ch12MF

X153CrMoV12

Properties :

High carbon and high chromium, ledeburitic 12 % Cr alloyed cold work tool steel, excellent abrasion resistance due to

a large volume of carbides in the microstructure, high cutting ability with edge holding properties, high compression strength, excellent deep hardenability and toughness properties, dimensional stability during heat treatment, high res-istance to softening at elevated temperatures. Suitable for nitriding and electrical discharge machining.

Applications :

High performance blanking, punching, stamping and cutting tools and dies up to 6 mm sheet thickness, thread rollings, chasers and dies, precision blanking dies, longitudinal and circular shear blades for plastic, paper and metal, cold form-ing and bending tools, tools for drawing, deep drawing and cold extrusion, hobbing tools, woodworking tools, milling cutters, reamers, broaches, pressing tools for the ceramics and pharmaceutical industries, cold piercers, measuring inst-ruments and gauges, rolling cutters and shaping wheels, cold pilger mandrels, beading, flanging and straightening rolls, plastic injection moulds, especially cutting tools of austenitic material when nitrided.

Physical Properties :

Density:at 20 °C 7,70 kg/dm3Thermal expansion between:20 °C and... °C, 10-6 m/(mK) Thermal conductivity:at 20 °C 20,0 W/(m.K)

100 °C200 °C300 °C400 °C500 °C

10,511,011,0 11,512,0

Heat Treatment :

Annealing:800 - 850 °C

Hardness after annealing:Max. 250 HB

Stress relieving:650 - 700 °C

Hot forming:1050 - 850 °C

Hardening:1020 - 1080 °C

Quenching media:Oil, Salt bath ( 220 - 250 °C or 500 - 550 °C )

Air or compressed air

Hardness after quenching:63 - 65 HRC

Hardness after tempering:

100 °C200 °C300 °C400 °C

64 HRC61 HRC59 HRC58 HRC

?Z ?ELYK TYCARET LTD.TTY.

12001100Hardening

10009002nd preheat stage

Air

800

700

6001st preheat stage

Tempering

500Salt bath

before nitriding

400 Cooling in furnace

300Salt bath

Tempering to

200working hardness

100Stress relieving

Oil

Time

Cleaning / Hardness test Heat Treatment Sequence

H a r d n e s s , H R C

T e m p e r a t u r e , °C

T e m p e r a t u r e , °C

Tempering Diagram

70

6662585450464238

X153CrMoV1234Heat treatment :30

1020 °C / Air 0

100200300400500600700800

Tempering temperature, °C

Time - Temperature - Transformation Diagram

1200

1100Austenitizing 1020 °C

1000

900

K

Ac1e (2K/min)800Ac1b (2K/min)

700P

100

600

A+K

1

650

2K/min

5000,380,9

10,2

18,0

5K/min

400300Ms

KgM

B

200

Ms

M

628

100870

870

743

348

211

010-1

100

101

102

103

104105106

Seconds Time

Minutes

1

10

100 1000

10000

Round Bars mm

10.512.513.514.515.516.518.520.522.525.528.530.532.835.840.845.850.855.860.866717681869196101.5111.5116.5121.5131.5141.5151.5162172182192202212222232242252.5262.5272.5

282.5

302.5

312.5

323

333

343

353

363

383

403

423

453

473

505

Square Bars mm

20

25

30

40

50

60

70

80

90

100

120

130

150

180

200

250

Flat Bars - Sheets mm Width x Thickness

25x 101520160x 202530405030x 10152025180x 2025304050

40x 61015202530200x 20253040505560708010012015050x 6101520253040220x 304050

60x

6101520253040

250x 202530405060708010012015020070x 101520253040300x 202530405060708010012015020080x

61015202530405060

350x 101520253035405060708010012090x 202530410x 20253035405055607080100120150200100x

61015202530354050607080

450x 304050607080

120x 10152025304050607080100510x 202530354050607080100120150200140x 30405070

610x 1.5

2 2.5

3 3.5

4 4.5

5 5.5

6

8

150x 152025304050607080100120

610x 1015202530354050607080