35_Checklist_for_Plastic_Industry

PLASTICS INDUSTRY

Checklist

The checklists contain a series of questions to which the company should answer yes or no. All questions to which the company answers yes constitute a working environment problem that must form part of an action plan which the company must draw up in connection with the checklist.

In relation to the checklists, the company must:

?answer all the questions in the checklist;

?comment on those questions to which the company answers “Yes” in the checklist’s action plan; ?consider what the cause of the working environment problems noted might be;

?draw up solutions to the working environment problems;

?comment on who is responsible for solving the working environment problems, and when these are expected to be solved;

?comment in writing on key working environment problems in the company that are not highlighted by the checklist.

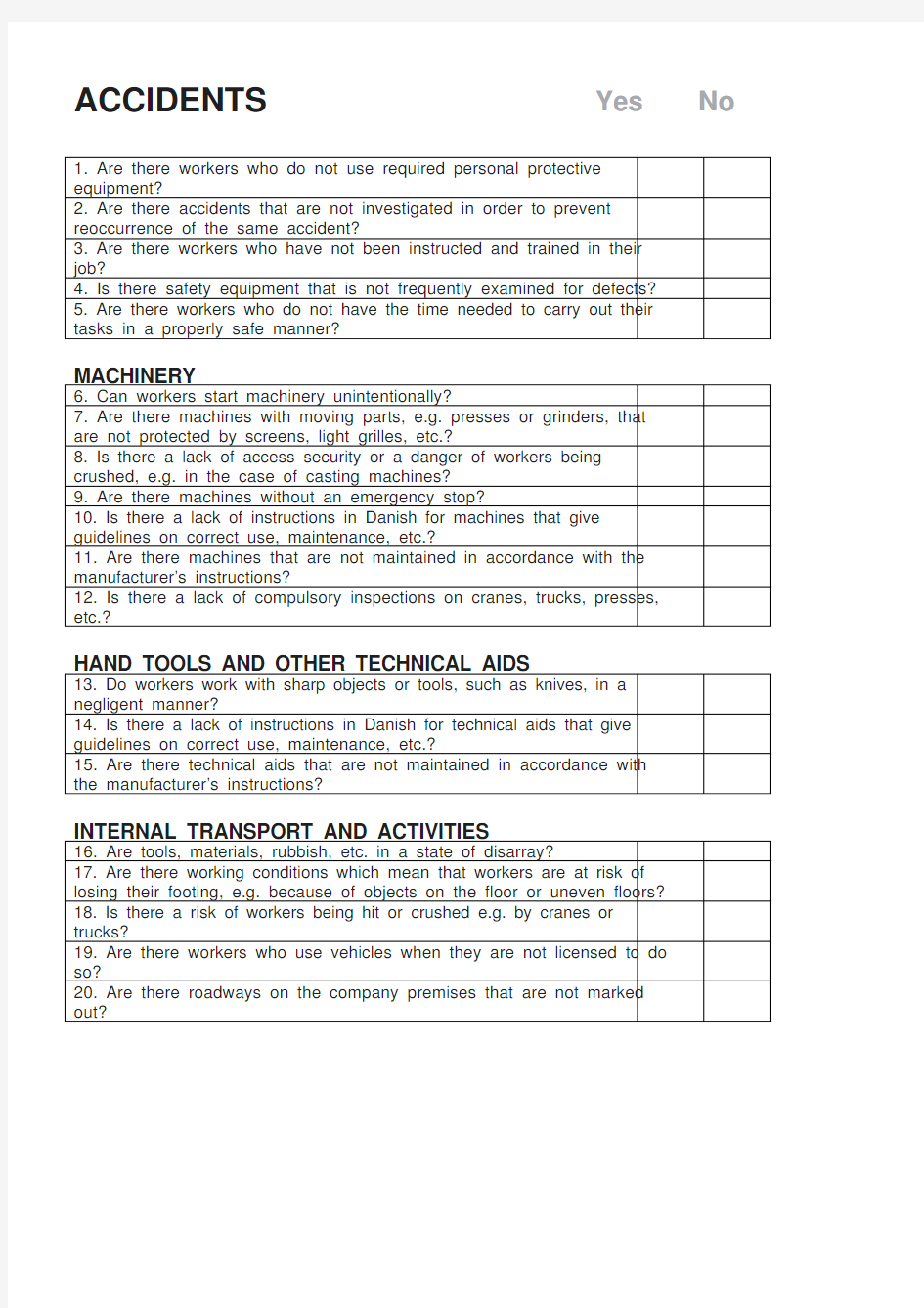

ACCIDENTS Yes No 1. Are there workers who do not use required personal protective

equipment?

2. Are there accidents that are not investigated in order to prevent

reoccurrence of the same accident?

3. Are there workers who have not been instructed and trained in their

job?

4. Is there safety equipment that is not frequently examined for defects?

5. Are there workers who do not have the time needed to carry out their

tasks in a properly safe manner?

MACHINERY

6. Can workers start machinery unintentionally?

7. Are there machines with moving parts, e.g. presses or grinders, that

are not protected by screens, light grilles, etc.?

8. Is there a lack of access security or a danger of workers being

crushed, e.g. in the case of casting machines?

9. Are there machines without an emergency stop?

10. Is there a lack of instructions in Danish for machines that give

guidelines on correct use, maintenance, etc.?

11. Are there machines that are not maintained in accordance with the manufacturer’s instructions?

12. Is there a lack of compulsory inspections on cranes, trucks, presses,

etc.?

HAND TOOLS AND OTHER TECHNICAL AIDS

13. Do workers work with sharp objects or tools, such as knives, in a

negligent manner?

14. Is there a lack of instructions in Danish for technical aids that give

guidelines on correct use, maintenance, etc.?

15. Are there technical aids that are not maintained in accordance with

the manufacturer’s instructions?

INTERNAL TRANSPORT AND ACTIVITIES

16. Are tools, materials, rubbish, etc. in a state of disarray?

17. Are there working conditions which mean that workers are at risk of

losing their footing, e.g. because of objects on the floor or uneven floors?

18. Is there a risk of workers being hit or crushed e.g. by cranes or

trucks?

19. Are there workers who use vehicles when they are not licensed to do

so?

20. Are there roadways on the company premises that are not marked

out?

MOTOR LOADS, FALLS ETC.

21. Are there situations in which workers make inappropriate twists or turns of the body?

22. Is there a lack of lifting gear for loads over 11 kg or for inappropriate lifting, pulling or pushing?

23. Are there slippery floors or walkways, e.g. because of spillages? OTHER DANGERS OF ACCIDENTS

24. Do people work beneath objects that are not supported, secured or safeguarded in some other way so they do not fall? CHEMICALS

25. Do workers work with hazardous chemicals (e.g. chemicals with orange warning symbols) in a negligent manner?

26. Does the company omit to check whether the hazardous chemicals that are used (e.g. adhesives and degreasing preparations containing organic solvents) can be replaced (substituted) by less hazardous chemicals?

27. Do workers work with hazardous chemicals even if a set of instructions for use in the workplace adapted to the conditions in the company has not been drawn up?

28. Have extractors not been fitted close to the point of origin for work processes and chemicals that give rise to air pollution, e.g. dust, fumes or vapour?

29. Is there a lack of ventilation that could remove such pollution?

30. Do workers work with chemicals in a form that is a greater risk to health, e.g. spray or powder form, than those in liquid or granulated form?

31. Are there workers who work with hazardous chemicals who have not been informed of the risks involved?

32. Are there workers who do not use personal protective equipment, even if this is required?

ERGONOMICS

HEAVY LIFTING

33. Are heavy objects or loads lifted manually, e.g. shaped parts and sacks of granulate?

34. Are many objects lifted in the course of a working day?

35. Are loads lifted in awkward working positions, e.g. far from the body, above shoulder-height or below knee-height?

ONE-SIDED REPETITIVE WORK

36. Is there one - sided, repetitive work – i.e. work where uniform movements are continually repeated for a large part of the working day –

e.g. in removal and packing operations?

37. Is one - sided, repetitive work carried out at high speed or under time constraints?

WORKING POSITIONS

38. Do people work in uncomfortable positions, e.g. squatting or with their hands above shoulder-height?

39. Do people work with a bent back or forward or backward bent neck?

40. Does the work involve stretching a long way?

41. Do people work in the same position for long periods of time?

42. Is the space in the workplace cramped?

NOISE

43. Are there workers who are exposed to noise which is so loud that they have to shout to communicate with a person standing 0.5 - 1 metre away?

44. Can the noise sources, e.g. transport systems and grinders, be dampened or enclosed more effectively or placed in a separate room? 45. Is there a lack of noise screens between sources of noise and work areas?

46. Does the company neglect to buy the lowest-noise machines on the market?

47. Are there workers who do not use ear-protectors, even when the noise is loud?

YOUNG PEOPLE

INSTRUCTION AND SUPERVISION

48. Are there young people below the age of 18 who have not received thorough instruction and training?

49. Do young people below the age of 18 work without being supervised by an adult?

50. Have the parents not been informed, where young people under 15 are employed, that they are subject to compulsory education? MACHINERY

51. Are there young people under 18 who work with dangerous machinery or in dangerous proximity to such machinery? CHEMICALS

52. Are there young people under 18 who work with hazardous chemicals or in dangerous proximity to them?

ERGONOMICS

53. Are there young people under 18 who lift objects over 12 kg several

times a day?

PSYCHOLOGICAL WORKING ENVIRONMENT EXCESSIVE DEMANDS

54. Is it necessary for workers to work very quickly?

LACK OF INFLUENCE

55. Do workers have little influence on the amount of work they do?

56. Do workers have little influence over how the work is carried out?

LACK OF SUPPORT

57. Is there a lack of help and support from colleagues?

58. Is there a lack of help and support from management?

LACK OF VARIETY

59. Is the work only slightly or not at all varied?

SHIFT WORK

60. Are there workers who mainly work outside normal working times,

e.g. in the early hours of the morning or during the night?

ABSENCE THROUGH SICKNESS

61. Are there conditions in the working environment that could contribute

to absence through sickness?

62. Could changes in the working environment reduce absence through

sickness?

OTHER

The enterprise must be aware that special requirements are placed on the WPA in a range of areas. Among other things, the following shall apply, which the enterprise must add to the checklist if the area is found in the company:

?working environment of pregnant women

?screen work

?biological agents

?carcinogenic substances and materials.

The company must also pay attention to the following aspects, which are not included in the checklist: ?indoor climate

WPA checklist - Action Plan

Cause of problem(s) Solution Person

responsible Time-limit and prioritisation

The company must consider how the action plan is to be followed up, whether the action plan has had the desired effect or whether adjustments must be made. The workplace assessment must be revised at least every three years, or in the event of changes in the work, working methods or working processes that affect health and safety at work.

Carried out by:

Employer Date Employee Date