VW13705_BEIBLATT_1_EN_2003-01-01

Vertragspartner erhalten die Norm nur über die zust?ndige Beschaffungsabteilung.

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without the prior written permission of a Standards Department of the Volkswagen Group.

Parties to a contract can only obtain this standard via the responsible procurement department.

VOLKSWAGEN AG

N o r m v o r A n w e n d u n g a u f A k t u a l i t ?t p r üf e n / C h e c k s t a n d a r d f o r c u r r e n t i s s u e p r i o r t o u s a g e .

T h e E n g l i s h t r a n s l a t i o n i s b e l i e v e d t o b e a c c u r a t e . I n c a s e o f d i s c r e p a n c i e s t h e G e r m a n v e r s i o n s h a l l g o v e r n .

Page 2

VW 137 05 Appendix 1: 2003-01

2.2 Metrological basis

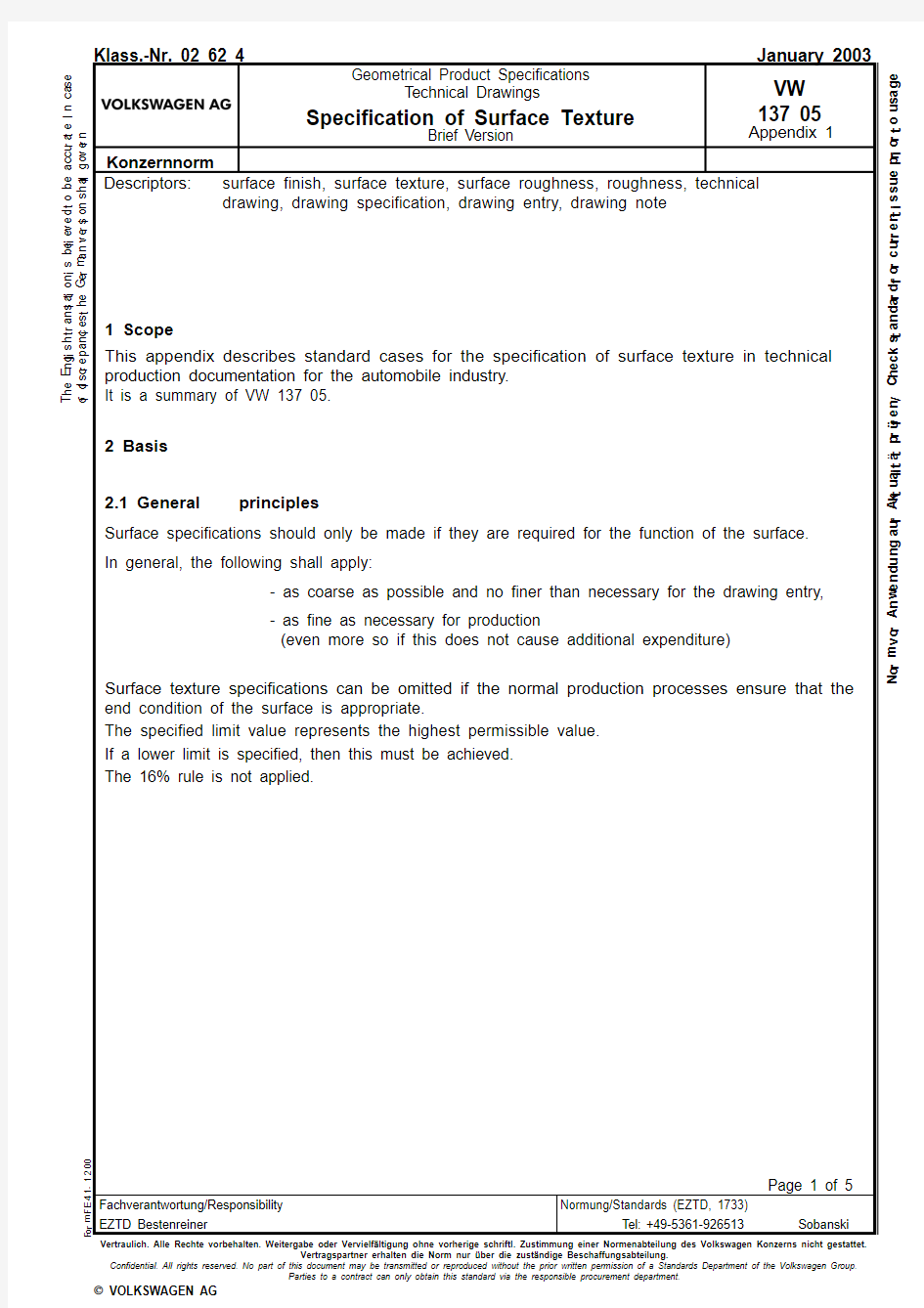

The standardized filter is the Gaussian filter according to DIN EN ISO 11562. The normal evaluation length comprises 5 sampling lengths.

Rz is the arithmetic average of the heights of the largest profile peaks and the depths of the deepest profile troughs of five consecutive sampling lengths

(see figure 1) 5

Z Z Z Z Z Rz 5

4321++++=

The original meaning and the designation of the maximum roughness Rmax are retained. Rmax is the highest value of the measurement of all sampling lengths (see figure 1). The use of the short wave filter λs is not permitted.

The long wave filter λc is used.

Run-in length Run-out length

Figure 1 – Forming the parameter Rmax from the roughness profile

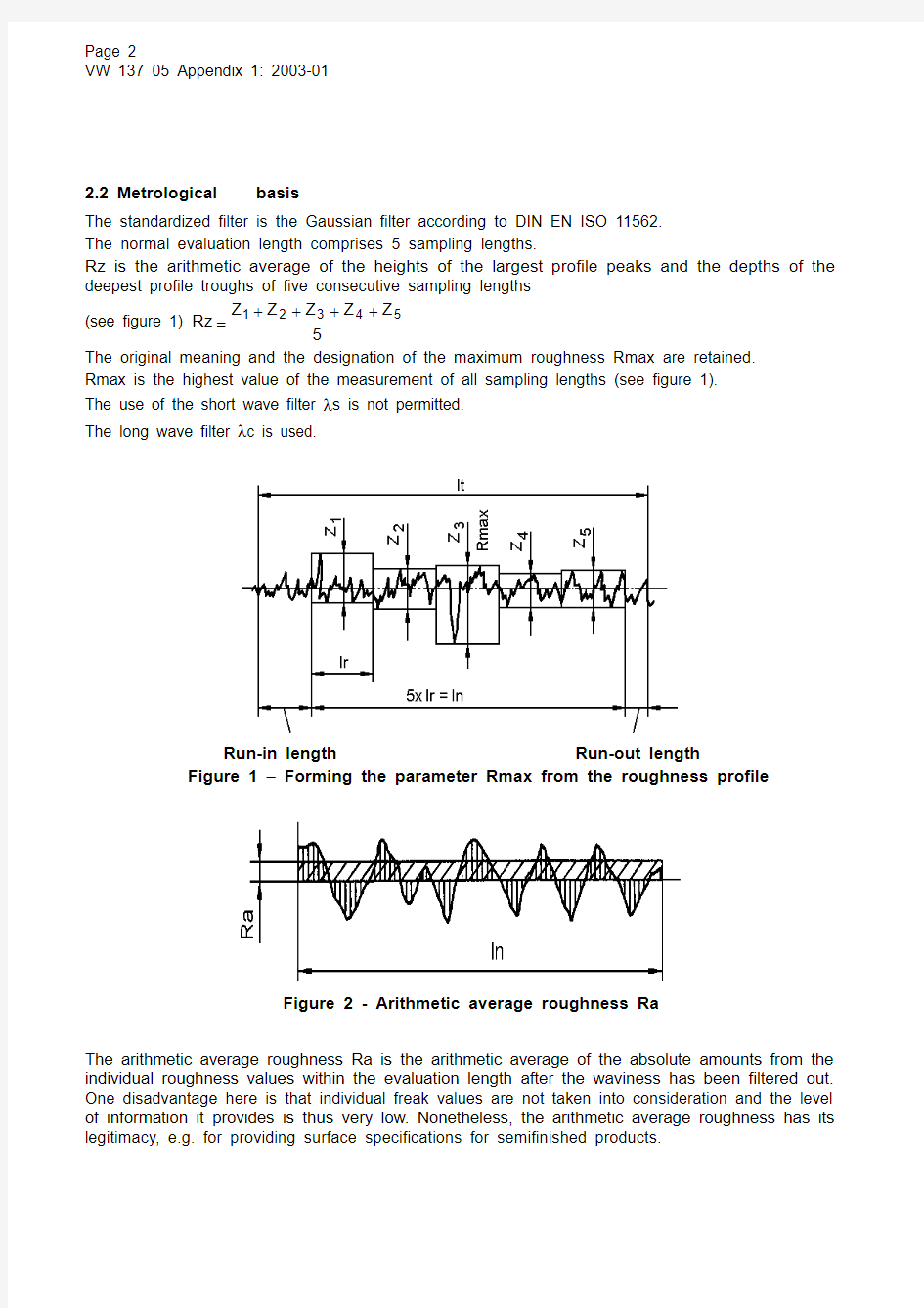

Figure 2 - Arithmetic average roughness Ra

The arithmetic average roughness Ra is the arithmetic average of the absolute amounts from the individual roughness values within the evaluation length after the waviness has been filtered out. One disadvantage here is that individual freak values are not taken into consideration and the level of information it provides is thus very low. Nonetheless, the arithmetic average roughness has its legitimacy, e.g. for providing surface specifications for semifinished products.

Page 3

VW 137 05 Appendix 1: 2003-01

3

Division of the possible surface specifications into individual elements

3.1 Explanation of the individual elements 3.1.1

Specifications of upper and lower (L) limits

Normally: Generally only the upper limit (surface parameter + limit value) is specified, e.g.:

The upper limit must not be exceeded.

Special case: In exceptional cases, there is the option of specifying only the lower limit (with the prefix L). If both the upper and lower limits are specified, then the upper limit is positioned on top with the lower limit beneath it (without additional marking), e.g.:

The upper limit may not be exceeded and the lower limit must be achieved.

L Rz 6.3

Rz 25 Rz 6.3

Rz 25

Page 4

VW 137 05 Appendix 1: 2003-01

3.1.2 Type of profile filter

The standardized filter is the Gaussian filter (DIN EN ISO 11562).

No specification is required.

3.1.2.1 Wave length limit

If there is a deviation from the wave length limit λc (cut off) assigned to the roughness (see DIN EN ISO 4288), the wave length limit and the number of evaluation lengths must be specified even if the normal evaluation length is used, e.g.

0.8x5/Rz 0.4

3.1.3 Surface

parameter

For all general applications, the normal roughness parameter Rz (according to DIN EN ISO 4287) shall be entered in the drawing.

In individual cases (e.g. surface specifications for semifinished products) it is useful to specify the Ra value.

Depending on the function, it can be useful to specify further parameters such as Rmax.

For porous and stratified heavy-duty contact surfaces, e.g. cylinder faces, the normal roughness parameter Rk may be supplemented by Rpk and Rvk (according to DIN EN ISO 13565-2).

For special applications, the appropriate parameter must be taken from the standards DIN EN ISO 4287 and DIN EN ISO 13565-2.

3.1.4 Evaluation

length

Normally: No evaluation length is specified for roughness parameters.

Thus the normal evaluation length applies.

The normal evaluation length ln comprises five sampling lengths lr(see figure 1).

E.g.:

Special case: If, e.g., the workpiece surface is very small such that the normal evaluation length cannot be used, the number of sampling lengths must be specified on the symbol.

E.g.:

Rz 25

2.5x3/Rz 25

Page 5

VW 137 05 Appendix 1: 2003-01

3.1.5 Preferred values

It is commercially sensible to stipulate preferred values for surface parameters, whereby no more than one point after the decimal point should be allowed. For Rz, values from the following series should be selected:

0.4 0.6 1 1.6 2.5 4 6.3 10 16 25 40 63 100

160 3.1.6

Type of production

Normally: All the symbols specified in section 5 of VW 137 05 are permitted.

NOTE The symbol “for all surfaces around a workpiece outline” detailed in DIN EN ISO 1302 shall be avoided. 3.1.7

Surface lay and structure thereof

Normally: No specification = any surface lay

3.1.8 Production process

Normally: No specification = any production process

4

Example of general type

General type, see figure 3

Figure 3 – General type