PBT 4830物性表

PBT 4830 台湾长春物性表数据资料

特性:含水量有玻纤30%,强度大,耐热性佳,难燃等级达1/8inch UL 94V-0 用途:连接器、冷却风扇、插座、线圈轴、汽机车零件、天关、电视机零件、整流器。

PBT 4830 台湾长春物性表

资料由长城塑胶提供

T e L 1 3 6 8 6 6 5 8 5 1 7

PBT 4830 台湾长春企业集团物性数据

①原料描述部分

规格级别:难燃强

化级

外观颜色:黑色本色

用途概述:连接器、冷却风扇、插座、线圈轴、汽机车零件、天关、电视机零件、整流器。

备注说明:特性:含水量有玻纤30%,强度大,耐热性佳,难燃等级达1/8inch UL 94V-0

②原料技术数据

性能项目试验条件[状

态]

测试方法测试数据数据单位

基本性能吸水率--- ASTM D-570 0.03 %

物理性能成型收缩

率

--- ASTM D-955 0.2-1.4 % 比重--- ASTM D-792 1.58-1.64 --- 玻璃纤维

含量

--- Ash 30 %

机械性能引张强度--- ASTM D-638 1100-1400 Kg/cm2

引张伸长

率

--- ASTM D-638 4月5日%

挠曲强度--- ASTM D-790 1500-2300 Kg/cm2

挠曲弹性

率

--- ASTM D-790 70000-100000 Kg/cm2 IZOD冲击

强度

--- ASTM D-256 7.0-13.0 Kg.cm/cm 洛氏硬度--- ASTM D-785 94 M-Scale

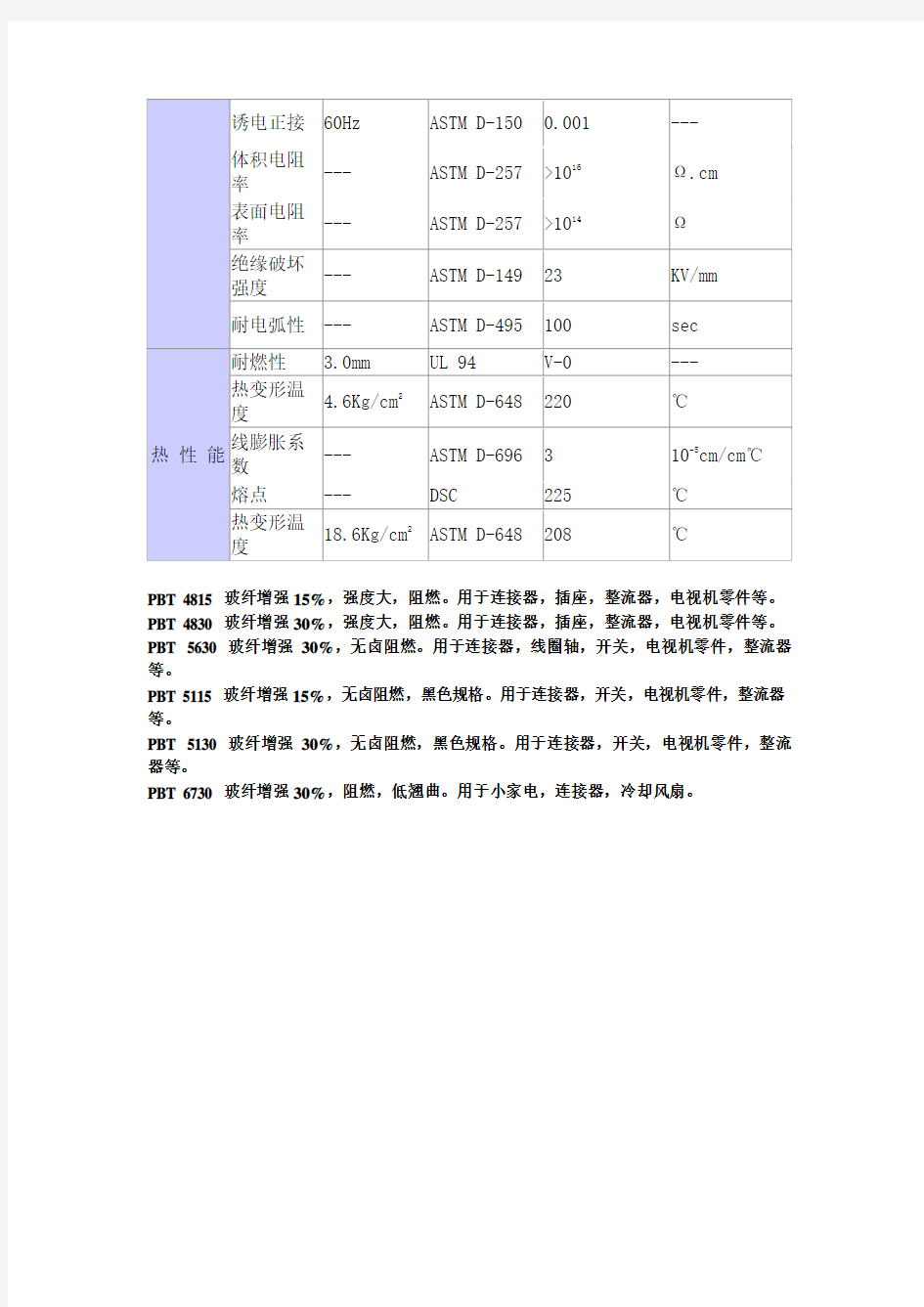

电气性能诱电率60Hz ASTM D-150 3.5 ---

诱电正接60Hz ASTM D-150 0.001 ---

体积电阻

率

--- ASTM D-257 >1016Ω.cm 表面电阻

率

--- ASTM D-257 >1014Ω

绝缘破坏

强度

--- ASTM D-149 23 KV/mm 耐电弧性--- ASTM D-495 100 sec

热性能耐燃性 3.0mm UL 94 V-0 ---

热变形温

度

4.6Kg/cm2ASTM D-648 220 ℃

线膨胀系

数

--- ASTM D-696 3 10-5cm/cm℃熔点--- DSC 225 ℃

热变形温

度

18.6Kg/cm2ASTM D-648 208 ℃

PBT 4815 玻纤增强15%,强度大,阻燃。用于连接器,插座,整流器,电视机零件等。PBT 4830 玻纤增强30%,强度大,阻燃。用于连接器,插座,整流器,电视机零件等。PBT 5630 玻纤增强30%,无卤阻燃。用于连接器,线圈轴,开关,电视机零件,整流器等。

PBT 5115 玻纤增强15%,无卤阻燃,黑色规格。用于连接器,开关,电视机零件,整流器等。

PBT 5130 玻纤增强30%,无卤阻燃,黑色规格。用于连接器,开关,电视机零件,整流器等。

PBT 6730 玻纤增强30%,阻燃,低翘曲。用于小家电,连接器,冷却风扇。

PBT SK642FR 杜邦 物性表

PBT SK642FR NC010杜邦DuPont Crastin?物性数据表: 产品文字由久隆塑胶原料提供TeL134******** Crastin?SK642FR是一种阻燃UL94V-01.5mm;GF15%玻璃纤维增强的聚对苯二甲酸乙二醇酯PBT,注塑成型。Crastin?SK642FR is a flame retardant,15%glass reinforced polybutylene terephtalate for injection molding.It is recognized as UL94V-0at1.5mm. 熔体体积流动速度(MVR)14cm3/10min ISO1133 温度250°C ISO1133 载荷5kg ISO1133 模塑收缩率(平行)0.7%ISO294-4,2577 模塑收缩率(垂直) 1.3%ISO294-4,2577 拉伸模量6500MPa ISO527-1/-2 断裂应力95MPa ISO527-1/-2 断裂伸长率3%ISO527-1/-2 拉伸蠕变模量(1h)6000MPa ISO899-1 拉伸蠕变模量(1000h)4800MPa ISO899-1 无缺口简支梁冲击强度(+23°C)53kJ/m2ISO179/1eU 无缺口简支梁冲击强度(-30°C)40kJ/m2ISO179/1eU 简支梁缺口冲击强度(+23°C)8kJ/m2ISO179/1eA 简支梁缺口冲击强度(-30°C)7kJ/m2ISO179/1eA 熔融温度(10°C/min)225°C ISO11357-1/-3 热变形温度(1.80MPa)203°C ISO75-1/-2 热变形温度(8.00MPa)116°C ISO75-1/-2 维卡软化温度(50°C/h50N)207°C ISO306 线性热膨胀系数(平行)50E-6/K ISO11359-1/-2 线性热膨胀系数(垂直)110E-6/K ISO11359-1/-2 1.5mm名义厚度时的燃烧性V-0class IEC60695-11-10 测试用试样的厚度 1.5mm IEC60695-11-10 UL注册UL-- 厚度为h时的燃烧性V-0class IEC60695-11-10 测试用试样的厚度0.8mm IEC60695-11-10 燃烧性-氧指数31%ISO4589-1/-2 相对介电常数.(100Hz) 3.7-IEC60250 相对介电常数.(1MHz) 3.5-IEC60250 介质损耗因子(100Hz)30E-4IEC60250 介质损耗因子(1MHz)170E-4IEC60250 体积电阻率>1E13Ohm*m IEC60093 表面电阻率1E15Ohm IEC60093 介电强度28kV/mm IEC60243-1 相对漏电起痕指数250-IEC60112

PBT+GF 物性表

PBT,30%glass fibres,injection moulding,flame retardant ISO Shortname:ISO 7792-1-PBT,GFHMR,09-110,GF30;ISO 1043-PBT GF FR(17)Property Test Condition Unit Standard guide value Rheological properties C Melt volume-flow rate 260°C;5kg cm3/(10min) ISO 1133-137C Molding shrinkage,parallel 60x60x2;250°C /WZ 80°C;600bar %ISO 294-40.3C Molding shrinkage,transverse 60x60x2;250°C /WZ 80°C;600bar %ISO 294-40.9Post-shrinkage,parallel 60x60x2;120°C;4h %ISO 294-40.1Post-shrinkage,transverse 60x60x2;120°C;4h % ISO 294-4 0.1 Mechanical properties (23°C/50%r.h.)C Tensile modulus 1mm/min MPa ISO 527-1,-211500C Tensile Stress at break 5mm/min MPa ISO 527-1,-2125C Tensile Strain at break 5mm/min %ISO 527-1,-2 2.1C Charpy impact strength 23°C kJ/m2ISO 179-1eU 50C Charpy impact strength -30°C kJ/m2ISO 179-1eU 50C Charpy notched impact strength 23°C kJ/m2ISO 179-1eA <10C Charpy notched impact strength -30°C kJ/m2ISO 179-1eA <10Izod impact strength 23°C kJ/m2ISO 180-1U 45Izod impact strength -30°C kJ/m2ISO 180-1U 45Izod notched impact strength 23°C kJ/m2ISO 180-1A <10Izod notched impact strength -30°C kJ/m2ISO 180-1A <10Flexural modulus 2mm/min MPa ISO 178-A 10500Flexural strength 2mm/min MPa ISO 178-A 200Flexural strain at flexural strength 2mm/min %ISO 178-A 2.6Ball indentation hardness N/mm2ISO 2039-1186C Puncture energy 23°C J ISO 6603-2 2.3C Puncture energy -30°C J ISO 6603-2 2.1C Puncture maximum force 23°C N ISO 6603-2669C Puncture maximum force -30°C N ISO 6603-2 649 Thermal properties C Melting temperature 10°C/min °C ISO 11357-1,-3225C Temperature of deflection under load 1.80MPa °C ISO 75-1,-2200C Temperature of deflection under load 0.45MPa °C ISO 75-1,-2220Vicat softening temperature 50N;120°C/h °C ISO 306205C Coefficient of linear thermal expansion,parallel 23to 55°C 10-4/K ISO 11359-1,-20.2C Coefficient of linear thermal expansion,transverse 23to 55°C 10-4/K ISO 11359-1,-20.9C Burning behavior UL 940.38mm Class UL 94V-0C Burning behavior UL 940.8mm Class UL 94V-0C Oxygen index Method A % ISO 4589-2 32 Pocan B 4239 000000 Page 1of 3

PBT+PC 基础创新塑料 553 物性表

PBT/PC基础创新塑料VALOX553物性表: 产品提供久隆塑胶原料tEl134******** GF30%玻璃纤维增强,阻燃V0,PBT+PC共混物,具有良好的翘曲的特点。应用:泵壳、轴承座、电器元件,聚光灯,电动马达,泵配件。30%GR PBT+PC,UL94V-0.Reduced warpage characteristics.Applications; appliance handles,spotlights,electric motors,pump housings,etc. 密度(73°F)1590公斤/立方米ASTM D792 吸水率(24小时)0.07%ASTM D570 熔体流动7.0g/10分钟负荷2.16公斤,温度250℃ 断裂伸长率 2.5%5毫米/分钟;ASTM D638 断裂拉伸强度110兆帕ASTM D638 弯曲模量6887.85兆帕ASTM D790 弯曲强度179兆帕ASTM D790 洛克硬度R118-ASTM D785 悬臂梁缺口冲击强度(1/8)的0.0854千焦/米ASTM D256 UL94燃烧性V-0-UL94测试厚度0.864毫米 氧指数34%ISO4589 0.46兆帕的热变形温度(66磅)205°C ISO75/Be 热变形温度在1.8兆帕(264磅)135°C ISO75/Ae 热释放速率(平行)21.6E-6/K ASTM D696 电介质强度(短时)25.6千伏/毫米ASTM D149 耗散因素(1兆赫)0.02-ASTM D150 电介质常数(1兆赫) 3.7-ASTM D150 体积电阻率>1E15欧姆*厘米ASTM D257 耐电弧性90?ASTM D495

PBT 4815物性表

PBT 4815物性表数据资料 特性:含有玻纤15%,强度大,成型容易,难燃等级达1/8inch,UL 94V-0 用途:连接器、冷却风扇、插座、线圈轴、汽机车零件、开关、电视机零件、整流器。 PBT 4815 台湾长春物性表 资料由长城塑胶提供 T e L 1 3 6 8 6 6 5 8 5 1 7 PBT 4815 台湾长春企业集团物性数据 ①原料描述部分 规格级别:难燃强 化级 外观颜色:黑色本色 用途概述:连接器、冷却风扇、插座、线圈轴、汽机车零件、开关、电视机零件、整流器。 备注说 明: 特性:含有玻纤15%,强度大,成型容易,难燃等级达1/8inch,UL 94V-0 ②原料技术数据 性能项目试验条件 [状态] 测试方法测试数据数据单位 基本性能吸水率--- ASTM D-570 0.03 % 物理性能成型收缩率--- ASTM D-955 0.4-2.0 % 比重--- ASTM D-792 1.43-1.52 --- 玻璃纤维含 量 --- Ash 15 % 机械性能引张强度--- ASTM D-638 900-1100 Kg/cm2 引张伸长率--- ASTM D-638 4-5.5 % 挠曲强度--- ASTM D-790 1400-1800 Kg/cm2 挠曲弹性率--- ASTM D-790 45000-65000 Kg/cm2 IZOD冲击强 度 --- ASTM D-256 5月7日Kg.cm/cm 洛氏硬度--- ASTM D-785 93 M-Scale 电气性能诱电率60Hz ASTM D-150 3.3 ---

诱电正接60Hz ASTM D-150 0.001 --- 体积电阻率--- ASTM D-257 >1016Ω.cm 表面电阻率--- ASTM D-257 >1014Ω 绝缘破坏强 度 --- ASTM D-149 22 KV/mm 耐电弧性--- ASTM D-495 90 sec 热性能耐燃性 3.0mm UL 94 V-0 --- 热变形温度 4.6Kg/cm2 ASTM D-648 220 ℃ 线膨胀系数--- ASTM D-696 5.5 10-5cm/cm℃熔点--- DSC 225 ℃ 热变形温度 18.6Kg/cm 2 ASTM D-648 205 ℃ PBT 1100 高粘度,超韧性,成型表面光滑。用于扣件组具,电脑键盘,文具外壳,旋钮开关等。 PBT 1200 高流动,表面光泽度良好。用于扣件组具,电脑键盘,文具外壳,旋钮开关等。PBT 2000 流动性佳,阻燃UL94V-0级。用于汽车零件,OA器材部件,瓦斯炉零件等。PBT 2100 流动性佳,阻燃UL94V-0级。用于汽车零件,OA器材部件,瓦斯炉零件等。PBT 3015 玻纤增强15%,低粘度,耐热性佳。用于汽车零件,马达端盖,碳刷座等。PBT 3020 玻纤增强20%,中粘度。用于汽车零件,马达端盖,碳刷座,工业产品零件等。PBT 3030 玻纤增强30%,高强度,耐热。用于汽车零件,马达端盖,碳刷座,工业产品零件等。 PBT 4115 含玻璃15%,高强度,阻燃。用于连接器,插座,线圈轴,电视机零件等。PBT 4120 含玻璃20%,强韧耐热性佳。用于连接器,插座,线圈轴,电视机零件等。PBT 4130 含玻璃30%,强韧耐热性佳。用于连接器,插座,线圈轴,电视机零件等。PBT 4140 含玻璃40%,高强度,低翘曲。用于连接器,插座,整流器,电视机零件等。PBT 4815 玻纤增强15%,强度大,阻燃。用于连接器,插座,整流器,电视机零件等。PBT 4830 玻纤增强30%,强度大,阻燃。用于连接器,插座,整流器,电视机零件等。PBT 5630 玻纤增强30%,无卤阻燃。用于连接器,线圈轴,开关,电视机零件,整流器等。 PBT 5115 玻纤增强15%,无卤阻燃,黑色规格。用于连接器,开关,电视机零件,整流器等。 PBT 5130 玻纤增强30%,无卤阻燃,黑色规格。用于连接器,开关,电视机零件,整流器等。 PBT 6730 玻纤增强30%,阻燃,低翘曲。用于小家电,连接器,冷却风扇。 PBT特性: 机械强度高,耐疲劳性和尺寸稳定性好,蠕变也小,这些性能在高温条件下也极少有变化。

杜邦 PBT HR5330HF 物性表

杜邦PBT HR5330HF本色NC010黑色BK503物性表: 产品提供久隆塑胶原料tEL134******** CRASTIN?HR5330HF是30%的玻璃纤维增强,高流量(HF),抗水解(HR)树脂。耐冲击性及强度出色的平衡性能。添加剂:润滑剂,、脱模助剂。特征:可焊、耐化学试剂、水解稳定。应用:汽车,电子电气。 熔体体积流动速度(MVR)8cm3/10min ISO1133 温度250℃ISO1133 载荷2.16kg ISO1133 模塑收缩率(平行)0.3%ISO294-4,2577 模塑收缩率(垂直) 1.0%ISO294-4,2577 拉伸模量8500MPa ISO527-1/-2 断裂应力110MPa ISO527-1/-2 断裂伸长率 2.9%ISO527-1/-2 无缺口简支梁冲击强度(+23°C)75kJ/m2ISO179/1eU 简支梁缺口冲击强度(+23°C)15kJ/m2ISO179/1eA 简支梁缺口冲击强度(-30°C)12kJ/m2ISO179/1eA 熔融温度(10°C/min)225°C ISO11357-1/-3 热变形温度(1.80MPa)205°C ISO75-1/-2 热变形温度(0.45MPa)220°C ISO75-1/-2 维卡软化温度(50°C/h50N)215°C ISO306 线性热膨胀系数(平行)21E-6/K ISO11359-1/-2 线性热膨胀系数(垂直)85E-6/K ISO11359-1/-2 1.5mm名义厚度时的燃烧性HB class IEC60695-11-10 测试用试样的厚度 1.5mm IEC60695-11-10 吸水性0.35%类似ISO62 吸湿性0.15%类似ISO62

杜邦物性表 PBT CRASTIN LW9330 BK851

DuPont ? Crastin ? PBT thermoplastic polyester resin Crastin ? LW9330 BK851 Identification Resin Identification ISO 1043PBT+SAN-GF30 Part Marking Code ISO 11469 >PBT+SAN-GF30< Mechanical Stress at Break ISO 527MPa (kpsi) 133 (19.3) Strain at Break ISO 527% 2.2 Tensile Modulus ISO 527MPa (kpsi)9600 (1390) Notched Charpy Impact Strength ISO 179/1eA kJ/m 28 Unnotched Charpy Impact Strength ISO 179/1eU kJ/m 2 50 Thermal Melting Temperature ISO 11357-1/-3 °C (°F) 10°C/min 225 (437) Flammability Flammability Classification IEC 60695-11-10 0.75mm HB Flammability Classification UL94 0.75mm HB Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated. The DuPont Oval Logo, DuPont?, The miracles of science? and Crastin? are trademarks or registered trademarks of DuPont Company. Copyright? 2005. 050420/050420 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102. https://www.wendangku.net/doc/9911916146.html, Crastin ? LW9330 BK851 is a 30% glass fiber reinforced, black polybutylene terephthalate alloy for injection molding. It has improved surface aesthetics, excellent dimensional stability and low warpage characteristics. Property Test Method Units Value

塑料PBT物性参数

塑料PBT物性参数 PBT是最坚韧的工程热塑材料之一,它是半结晶材料,有非常好的化学稳定性、机械强度、电绝缘特性和热稳定性。这些材料在很广的环境条件下都有很好的稳定性。 PBT吸湿特性很弱。非增强型PBT的张力强度为50MPa,玻璃添加剂型的PBT 张力强度为170MPa.玻璃添加剂过多将导致材料变脆。PBT的;结晶很迅速,这将导致因冷却不均匀而造成弯曲变形。对于有玻璃添加剂类型的材料,流程方向的收缩率可以减小,但与流程垂直方向的收缩率基本上和普通材料没有区别。一般材料收缩率在1.5%~2.8%之间。含30%玻璃添加剂的材料收缩0.3%~1.6%之间。熔点(225%C)和高温变形温度都比PET材料要低。维卡软化温度大约为170C.玻璃化转换温度(glass trasitio temperature)在22C到43C之间。由于PBT的结晶速度很高,因此它的粘性很低,塑件加工的周期时间一般也较低。 PBT树脂注塑模工艺条件 干燥处理:这种材料在高温下很容易水解,因此加工前的干燥处理是很重要的。建议在空气中的干燥条件为120C,6~8小时,或者150C,2~4小时。湿度必须小于0.03%.如果用吸湿干燥器干燥,建议条件为150C,2.5小时。 熔化温度:225~275C,建议温度:250C。模具温度:对于未增强型的材料为 40~60C。要很好地设计模具的冷却腔道以减小塑件的弯曲。热量的散失一定要快而均匀。建议模具冷却腔道的直径为12mm。 注射压力:中等(最大到1500bar)。 注射速度:应使用尽可能快的注射速度(因为PBT的凝固很快)。流道和浇口:建议使用圆形流道以增加压力的传递(经验公式:流道直径=塑件厚度+1.5mm)。可以使用各种型式的浇口。也可以使用热流道,但要注意防止材料的渗漏和降解。浇口直径应该在0.8~1.0*t之间,这里 t是塑件厚度。如果是潜入式浇口,建议最小直径为 0.75mm.典型用途家用器具(食品加工刀片、真空吸尘器元件、电风扇、头发干燥机壳体、咖啡器皿等),电器元件(开关、电机壳、保险丝盒、计算机键盘按键等),汽车工业(散热器格窗、车身嵌板、车轮盖、门窗部件等)。 a、机械性能:强度高、耐疲劳性、尺寸稳定、蠕变也小(高温条件下也极少有变化); b、耐热老化性:增强后的UL温度指数达120~140℃(户外长期老化性也很好); c、耐溶剂性:无应力开裂; d、对水稳定性:PBT遇水易分解(高温、高湿环境下使用需谨慎);

PBT+30GF物性

SCHEDA TECNICA TECHNICAL DATA SHEET Versione 1 Aggiornata: 03/03/11 Le informazioni contenute in questo documento vengono fornite in buona fede e con scopo puramente indicativo da valutare attentamente in funzione delle esigenze progettuali. I valori sono riferiti a provini stampati e condizionati: 40h - 23°C - 50% U.R. Prodotto non idoneo per applicazioni alimentari e/o medicali se non diversamente indicato. Non deve essere considerato in alcun caso come un vincolo contrattuale o garanzia da parte nostra, specialmente in caso di utilizzo improprio dei nostri prodotti da parte di terzi. The information contained herein are supplied in good faith and given purely as an indication. Properties should be carefully evaluated for all projects requirements. Values are referred to moulded samples conditioned for 40h - 23°C - 50% U.R. Unless otherwise posted this product is not suitable for food and/or medical application and use. They shall not be considered in any way as a formal commitment or warranty on our part especially in case of improper use of our products from third parties. SCT REV. 1 DEL 01/01/11

PBT物性

PBT容易水解。如果在加工过程中熔融时水分含量过高,就会发生降解。这会导致分子链断裂,从而引起平均分子量下降。实际上,这表明其自身耐冲击性和弹性的损失。强度的下降通常并不明显。通过依照DIN ISO 1628-5测定粘度值或依照ISO 1133测定熔体体积指数,可以证实材料的降解。因此,为了保证PBT制成件具有高质量且质量波动小,应特别注意粒料的预处理和加工。加工时,PBT的水分含量通常小于0.04%。因此,为了保证生产的可靠性,通常应规定预干燥,并且应经由封闭的输送系统给机器加载。在市场上可买到适用的设备。对于批料的添加,例如在自身染色情况下,也建议进行对PBT材料预干燥。为了防止形成凝结水,只有当其达到加工区内的一般温度时,才可打开存放于常温室内的容器。这可能需要非常长的时间。测量表明:原先在5℃下的25-kg袋的内部只有在48小时之后,才会达到加工区内的20℃。在各种干燥机系统中,空气干燥机已被证明在技术和成本上均具有优势。在80-120℃下这些装置的干燥时间为4个小时。 PBT--在短暂生产中断期间,应将螺杆进至最前端位置。并且当停工时间相对较长时,应另外降低PBT料筒温度。在中断后重新启动之前,必须彻底清洗。在更换材料时,必须预先清洁螺杆和料筒。经证实,高分子量的HDPE以及玻璃纤维增强型HDPE和GFPP对螺杆和料筒具有良好的清洁作用。再粉碎的部件和浇口通常可以再加工。但是,由于PBT 在各种加工循环中可能会出现不同程度的降解,应首先检查在相关情况中降解的程度。对溶液中粘度值或熔体粘度的检查可提供有用的信息。如果在第一道中对材料进行了适当的处理,则通常可将高达25% 的重新造粒的材料与新的粒料混合,材料的特性不会有明显下降。对于阻燃PBT产品,必须遵守容许的再粉碎数量的限制(如UL规格)。当增加再粉碎料时,必须注意是否进行了足够的预干燥,通过使用母料自着色,可以得到非我们产品系列中的其它色调。在选择母料时,应注意与PBT的高度兼容,使其性能范围不受影响。我们建议采用基于PBT的色母料,对于阻燃产品,必须注意:只使用不会改变其阻燃等级的母料。

pbt物性表

長春人造樹脂廠股份有限公司 Chang Chun Plastics Co Ltd GRADE 1200-211D 1200-211L 1200-211M 1200-211F Intrinsic Viscosity (dl/g) 0.75±0.02 0.79±0.02 0.83±0.02 0.85±0.02 COOH Groups (meq/kg) ≦50 ≦50 ≦50 ≦50 color L* ≧84 ≧84 ≧84 ≧84 color b* ≦2 ≦2 ≦2 ≦2 Melting Flow Index (g/10 min) 64-78 50-78 41-50 37-46 Specific Gravity 1.30-1.32 1.30-1.32 1.30-1.32 1.30-1.32 Tensile Strength (kg/cm2) 500-600 500-600 500-600 500-600 Tensile Elongation (%) ≧30 ≧30 ≧50 ≧50 Izod Impact Strength (kg-cm/cm) ≧4.0 ≧4.0 ≧4.5 ≧4.5 Dielectric Strength (kV/mm) ≧20 ≧20 ≧20 ≧20 Melting Point (℃) 225±2 225±2 225±2 225±2 Water content (wt%) <0.3 <0.3 <0.3 <0.3 1. I.V. is analyzed by Phenol / Tetrachloroethane=3:2 solvent in 30℃. 2. The analyzed of M.I. is determined in 235℃, 2.16kg. 3. The physical property table is for reference only. GRADE 1100-211D 1100-211L 1100-211M 1100MB Intrinsic Viscosity (dl/g) 0.88±0.02 0.94±0.02 1.00±0.02 1.04±0.04 COOH Groups (meq/kg) ≦40 ≦50 ≦50 ≦40 color L* ≧84 ≧84 ≧84 ≧84 color b* ≦2.8 ≦3 ≦3 ≦2.5 Melting Flow Index (g/10 min) 250℃32-40 46-58 23-29 18-22 14-20 21-30 Specific Gravity 1.30-1.32 1.30-1.32 1.30-1.32 1.30-1.32 Tensile Strength (kg/cm2) 500-600 500-600 500-600 500-600 Tensile Elongation (%) ≧50 ≧90 ≧120 ≧120 Izod Impact Strength (kg-cm/cm) ≧4.5 ≧4.5 ≧5.0 ≧5.0 Dielectric Strength (kV/mm) ≧20 ≧20 ≧20 ≧20 Melting Point (℃) 225±2 225±2 225±2 225±2 Water content (wt%) <0.3 <0.3 <0.3 <0.3

PBT 杜邦 S600F10 物性表

PBT杜邦DUPONT S600F10物性表: 产品提供久隆塑胶原料tEL134******** PBT DUPONT Crastin?S600F10NC010是未增强聚对苯二甲酸乙二醇酯纯树脂,润滑,高粘度,注塑成型。特别适宜成型厚壁产品。加工方法:注塑,异型材挤出成型,其它挤出成型,表面涂层. Crastin?S600F10is an unreinforced,lubricated,high viscosity polybutylene terephtalate for injection molding. 熔体体积流动速度(MVR)10cm3/10min ISO1133 温度250°C ISO1133 载荷 2.16kg ISO1133 模塑收缩率(平行) 1.7%ISO294-4,2577 模塑收缩率(垂直) 1.6%ISO294-4,2577 拉伸模量2700MPa ISO527-1/-2 屈服应力57MPa ISO527-1/-2 屈服伸长率4%ISO527-1/-2 名义断裂伸长率>50%ISO527-1/-2 拉伸蠕变模量(1h)2300MPa ISO899-1 拉伸蠕变模量(1000h)1800MPa ISO899-1 无缺口简支梁冲击强度(+23°C)N kJ/m2ISO179/1eU 无缺口简支梁冲击强度(-30°C)N kJ/m2ISO179/1eU 简支梁缺口冲击强度(+23°C) 5.4kJ/m2ISO179/1eA 简支梁缺口冲击强度(-30°C)4kJ/m2ISO179/1eA 熔融温度(10°C/min)225°C ISO11357-1/-3 玻璃化转变温度(10°C/min)55°C ISO11357-1/-2 热变形温度(1.80MPa)50°C ISO75-1/-2 热变形温度(0.45MPa)115°C ISO75-1/-2 维卡软化温度(50°C/h50N)175°C ISO306 线性热膨胀系数(平行)130E-6/K ISO11359-1/-2 线性热膨胀系数(垂直)130E-6/K ISO11359-1/-2 1.5mm名义厚度时的燃烧性HB class IEC60695-11-10 测试用试样的厚度 1.5mm IEC60695-11-10 UL注册UL-- 厚度为h时的燃烧性HB class IEC60695-11-10 测试用试样的厚度0.8mm IEC60695-11-10 UL注册UL-- 燃烧性-氧指数22%ISO4589-1/-2 相对介电常数.(100Hz) 3.8-IEC60250 相对介电常数.(1MHz) 3.2-IEC60250 介质损耗因子(100Hz)20E-4IEC60250 介质损耗因子(1MHz)200E-4IEC60250 体积电阻率>1E13Ohm*m IEC60093

PBT 4830物性表

PBT 4830 台湾长春物性表数据资料 特性:含水量有玻纤30%,强度大,耐热性佳,难燃等级达1/8inch UL 94V-0 用途:连接器、冷却风扇、插座、线圈轴、汽机车零件、天关、电视机零件、整流器。 PBT 4830 台湾长春物性表 资料由长城塑胶提供 T e L 1 3 6 8 6 6 5 8 5 1 7 PBT 4830 台湾长春企业集团物性数据 ①原料描述部分 规格级别:难燃强 化级 外观颜色:黑色本色 用途概述:连接器、冷却风扇、插座、线圈轴、汽机车零件、天关、电视机零件、整流器。 备注说明:特性:含水量有玻纤30%,强度大,耐热性佳,难燃等级达1/8inch UL 94V-0 ②原料技术数据 性能项目试验条件[状 态] 测试方法测试数据数据单位 基本性能吸水率--- ASTM D-570 0.03 % 物理性能成型收缩 率 --- ASTM D-955 0.2-1.4 % 比重--- ASTM D-792 1.58-1.64 --- 玻璃纤维 含量 --- Ash 30 % 机械性能引张强度--- ASTM D-638 1100-1400 Kg/cm2 引张伸长 率 --- ASTM D-638 4月5日% 挠曲强度--- ASTM D-790 1500-2300 Kg/cm2 挠曲弹性 率 --- ASTM D-790 70000-100000 Kg/cm2 IZOD冲击 强度 --- ASTM D-256 7.0-13.0 Kg.cm/cm 洛氏硬度--- ASTM D-785 94 M-Scale 电气性能诱电率60Hz ASTM D-150 3.5 ---

PBT+SAN 杜邦 LW9330 GF30% 物性表 注塑参数

PBT+SAN杜邦LW9330GF30%物性数据表: 产品提供久隆塑胶原料tEl134******** 30%的玻璃纤维增强聚丁烯terephtalate混合,含润滑剂\脱模剂,注射成型。超声波可焊接、抗弯曲、吸潮性差、耐化学性良好、可加工性良好。它具有优异的表面光泽,尺寸稳定性和低翘曲。典型应用:连接器、汽车车前灯组件。 Crastin?LW9330NC010-(PBT+SAN)-I-GF30-DuPont 模压收缩率(平行)0.002毫米/毫米ASTM D955 密度(73°F)1430公斤/立方米ASTM D792 拉伸模量8999.99兆帕ASTM D638 拉伸强度131兆帕ASTM D638 断裂伸长率2%ASTM D638 弯曲模量8275兆帕ASTM D790 弯曲强度179兆帕ASTM D790 悬臂梁缺口冲击强度(1/8)的0.096千焦/米ASTM D256 低温悬臂梁缺口冲击强度(低温度)0.096千焦/米ASTM D256温度-40°C UL94燃烧性HB-UL94测试厚度0.75毫米 热变形温度@66PSI215℃ASTM D648 热变形温度@264磅190℃ASTM D648 熔点225°C ASTM D3418 电介质强度(短时)23千伏/毫米ASTM D149 耗散因素(1兆赫)0.013-ASTM D150 电介质常数(1兆赫) 3.4-ASTM D150 表面电阻率>1E15欧姆ASTM D257 体积电阻率>1E15欧姆*厘米ASTM D257 PBT+SAN杜邦LW9330GF30%注塑成型参数:干燥推荐的=是干燥温度=110-130℃干燥的时间,除湿后的的烘干机=2-4小时加工水分含量=<0.04%以上加工熔体温度的最佳=260℃熔体的温度范围内

PBT 357物性表

V alox* Resin 357 A sia Pacific: COMMERCIAL PBT + PC, Unreinforced, impact modified, UL94V-0 rated. Applications like bobbins, switches and enclosures. T YPICAL PROPERTIES 1 TYPICAL VALUE UNIT STANDARD M ECHANICAL T ensile Stress, yld, Type I, 50 mm/min 48M Pa A STM D 638T ensile Stress, brk, Type I, 50 mm/min 48M Pa A STM D 638T ensile Strain, yld, Type I, 50 mm/min 5%A STM D 638T ensile Strain, brk, Type I, 50 mm/min 110%A STM D 638T ensile Modulus, 5 mm/min 2020M Pa A STM D 638F lexural Stress, yld, 1.3 mm/min, 50 mm span 83M Pa A STM D 790F lexural Stress, brk, 1.3 mm/min, 50 mm span 83M Pa A STM D 790F lexural Modulus, 1.3 mm/min, 50 mm span 2060M Pa A STM D 790H ardness, Rockwell R 117-A STM D 785I MPACT Izod Impact, unnotched, 23°C 3204J /m A STM D 4812 Izod Impact, notched, 23°C 534J /m A STM D 256 Izod Impact, notched, -30°C 153J /m A STM D 256 Gardner, 23°C 43J A STM D 3029 Modified Gardner, 23°C 43J A STM D 3029 Instrumented Impact Total Energy, 23°C 35J A STM D 3763 Izod Impact, notched 80*10*4 +23°C 45k J/m2I SO 180/1A Izod Impact, notched 80*10*4 -30°C 10k J/m2I SO 180/1A Charpy 23°C, V-notch Edgew 80*10*4 sp=62mm 45k J/m2I SO 179/1eA T HERMAL V icat Softening Temp, Rate B/50 134°C A STM D 1525H DT, 0.45 MPa, 6.4 mm, unannealed 138°C A STM D 648H DT, 1.82 MPa, 6.4 mm, unannealed 99 °C A STM D 648 CTE, -40°C to 40°C, flow 9.18E-051/°C A STM E 831 CTE, -40°C to 40°C, xflow 8.4E-051/°C A STM E 831 CTE, 60°C to 138°C, flow 1.24E-041/°C A STM E 831 CTE, -40°C to 40°C, flow 7.2E-05 1/°C I SO 11359-2 PLEASE CONTACT YOUR LOCAL SALES OFFICE FOR AVAILABILITY IN YOUR AREA DISCLAIMER : THE MATERIALS AND PRODUCTS OF THE BUSINESSES MAKING UP THE SABIC INNOVATIVE PLASTICS 1) T ypical values only. Variations within normal tolerances are possible for variose colours.All values are measured at least after 48 hours s torage at 230C/50% relative humidity. All properties, except the melt volume rate are measured on injection m oulded samples.All samples are prepared according to ISO 294. 2) O nly typical data for material selection purpose.Not to be used for p art or tool design. 3) T his rating is not intended to reflect hazards presented by this or any o ther material under actual fire conditions.4) O wn measurement according to UL. 5) Measurements made from laboratory test coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article. Source, GMD, Last Update:11/09/2009 COMPANY, ITS SUBSIDIARIES AND AFFILIATES ("SABIC IP"), ARE SOLD SUBJECT TO SABIC IP' S STANDARD CONDITIONS OF SALE, WHICH ARE INCLUDED IN THE APPLICABLE DISTRIBUTOR OR OTHER SALES AGREEMENT, PRINTED ON THE BACK OF ORDER ACKNOWLEDGMENTS AND INVOICES, AND AVAILABLE UPON REQUEST. ALTHOUGH ANY INFORMATION, RECOMMENDATIONS, OR ADVICE CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SABIC IP MAKES NO WARRANTY OR GUARANTEE, EXPRESS OR IMPLIED, (I) THAT THE RESULTS DESCRIBED HEREIN WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (II) AS TO THE EFFECTIVENESS OR SAFETY OF ANY DESIGN INCORPORATING SABIC IP MATERIALS, PRODUCTS, RECOMMENDATIONS OR ADVICE. EXCEPT AS PROVIDED IN SABIC IP' S STANDARD CONDITIONS OF SALE, SABIC IP AND ITS REPRESENTATIVES SHALL IN NO EVENT BE RESPONSIBLE FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS OR PRODUCTS DESCRIBED HEREIN.Each user bears full responsibility for making its own determination as to the suitability of SABIC IP' s materials, products, recommendations, or advice for its own particular use. Each user must identify and perform all tests and analyses necessary to assure that its finished parts incorporating SABIC IP materials or products will be safe and suitable for use under end-use conditions. Nothing in this or any other document, nor any oral recommendation or advice, shall be deemed to alter, vary, supersede, or waive any provision of SABIC IP' s Standard Conditions of Sale or this Disclaimer, unless any such modification is specifically agreed to in a writing signed by SABIC IP. No statement contained herein concerning a possible or suggested use of any material, product or design is intended, or should be construed, to grant any license under any patent or other intellectual property right of SABIC Innovative Plastics Company or any of its subsidiaries or affiliates covering such use or design, or as a recommendation for the use of such material, product or design in the infringement of any patent or other