专业英语翻译2-main

Load test of a plain concrete arch railway bridge of 20-m span

Mohammad.-S.Marefat

a,*

,Esmaeel Ghahremani-Gargary a ,Shervan Ataei

b

a Department of Civil Engineering,Faculty of Engineering,University of Tehran,P.O.Box 11365-4563,Tehran,Iran b

Division of Civil Engineering,Faculty of Engineering,University of Tarbiat Modarres,P.O.Box 11365-4563,Tehran,Iran

Received 1June 2003;received in revised form 13April 2004;accepted 14April 2004

Available online 15June 2004

Abstract

To evaluate the remaining strength of a plain concrete arch bridge,dynamic and static load test was carried out.In the static test,up to 7300kN of weight was applied,and in the dynamic test,a 1200kN locomotive was used.The bridge demonstrated relatively sti?and strong response,despite initiation of enormous cracks,and it yielded under load levels much greater than the service load.The performance could be compared to a multi-layered continuous structure rather than to an arch form.The study showed that the bridge still enjoyed relatively large strength reserve and proper dynamic performance,despite deep and wide cracks,su?ering from carbonation,and being more than 60-year old.ó2004Elsevier Ltd.All rights reserved.

Keywords:Railway bridge;Plain concrete arch;Masonry bridge;Load tests

1.Introduction

Assessment of the remaining load carrying capacity of masonry arch bridges has been studied by many re-searchers in the recent years.Most of the masonry bridges have been built several decades ago,and have been designed for live loads and service conditions that have been changed over time.The residual strength of those structures cannot be predicted,in a reliable man-ner,because of time dependent e?ects such as fatigue and creep,environmental defects such as cracking and corrosion,participation of non-structural elements such as ?ll material and pavement layers,variation in restrain conditions,and di?erences between as-built and design speci?cations.To overcome such restrictions,?eld tests provide a dependable solution.

On the basis of construction material,masonry arch bridges may be divided into three groups,namely,brickwork arch,stone arch,and plain concrete arch.Field and laboratory tests on brickwork and stone ar-ches have been reported frequently (e.g.[1–10]).Full-

scale test of plain concrete arches has been published in a few documents [11,12]and is discussed in this paper.In this document,load testing of a plain concrete arch bridge is described.The bridge is more than 60-year old,and su?ers from severe cracking and relatively deep carbonation.The number of this type of bridges,in the railway network of Iran,exceeds several thousands.There are concerns about the safety and serviceability of those bridges under increasing axle load and tra?c volume.It was decided to perform load test on Bridge Km-23that has been decommissioned in the recent years.

2.Description of the bridge

The bridge is located at kilometer 23of Tehran-Qom Railway and consists of two identical 20-m arches.The structure su?ers from extensive cracking,at the crowns of all spans,and environmental damage.The crack width,at the so?t,varies between 10and 30mm and extends throughout the entire section.There are also visible cracks,up to 3mm wide and 100–600mm long,at the springing of all spans.Reinforcement has not been used and all structural parts,including the arch,

*

Corresponding author.Tel.:+9821-611-2292;fax:+9821-646-1024.E-mail address:mmarefat@ut.ac.ir (M.-S.Marefat).

0950-0618/$-see front matter ó2004Elsevier Ltd.All rights reserved.

doi:10.1016/j.conbuildmat.2004.04.025

Construction and Building Materials 18(2004)

661–667

Construction and Building

MATERIALS

https://www.wendangku.net/doc/6715818376.html,/locate/conbuildmat

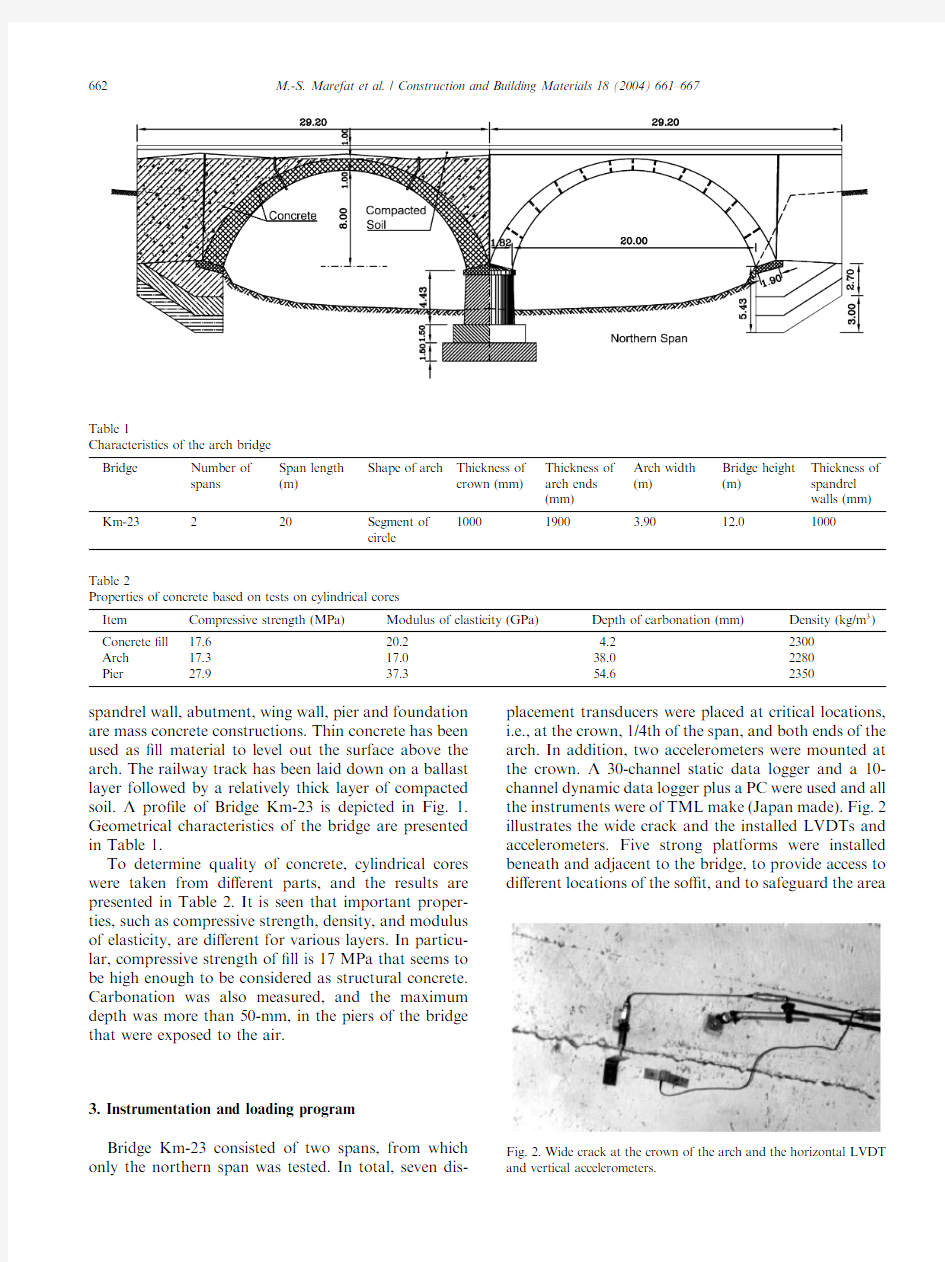

spandrel wall,abutment,wing wall,pier and foundation are mass concrete constructions.Thin concrete has been used as ?ll material to level out the surface above the arch.The railway track has been laid down on a ballast layer followed by a relatively thick layer of compacted soil.A pro?le of Bridge Km-23is depicted in Fig.1.Geometrical characteristics of the bridge are presented in Table 1.

To determine quality of concrete,cylindrical cores were taken from di?erent parts,and the results are presented in Table 2.It is seen that important proper-ties,such as compressive strength,density,and modulus of elasticity,are di?erent for various layers.In particu-lar,compressive strength of ?ll is 17MPa that seems to be high enough to be considered as structural concrete.Carbonation was also measured,and the maximum depth was more than 50-mm,in the piers of the bridge that were exposed to the air.

3.Instrumentation and loading program

Bridge Km-23consisted of two spans,from which only the northern span was tested.In total,seven dis-placement transducers were placed at critical locations,i.e.,at the crown,1/4th of the span,and both ends of the arch.In addition,two accelerometers were mounted at the crown.A 30-channel static data logger and a 10-channel dynamic data logger plus a PC were used and all the instruments were of TML make (Japan made).Fig.2illustrates the wide crack and the installed LVDTs and accelerometers.Five strong platforms were installed beneath and adjacent to the bridge,to provide access to di?erent locations of the so?t,and to safeguard the

area

Table 1

Characteristics of the arch bridge Bridge

Number of spans Span length (m)Shape of arch

Thickness of crown (mm)Thickness of arch ends (mm)Arch width (m)Bridge height (m)Thickness of spandrel walls (mm)Km-23

2

20

Segment of circle

1000

1900

3.90

12.0

1000

Table 2

Properties of concrete based on tests on cylindrical cores Item Compressive strength (MPa)Modulus of elasticity (GPa)Depth of carbonation (mm)Density (kg/m 3)Concrete ?ll 17.620.2 4.22300Arch 17.317.038.02280Pier

27.9

37.3

54.6

2350

Fig.2.Wide crack at the crown of the arch and the horizontal LVDT and vertical accelerometers.

662M.-S.Marefat et al./Construction and Building Materials 18(2004)661–667

against falling debris or probable structural collapse during the test.

In the static test,about 6000kN of out-of-service U-33rails were used to make 40-kN weights.The weights were laid down in parallel,perpendicular to the bridge axis,and at a distance from each other to ensure a uniform distribution of load.In addition,1280kN of lead,comprised 12-kN weights,was used to reach a total load of 7280kN.The load was increased gradually,and displacements were measured at every 240-kN increment of load.Fig.3shows Bridge Km-23in the static test.In the dynamic test,a 1200-kN 6-axle locomotive passed above the bridge at speeds of 10,20,40,60,and 80km/h and the arch response,in terms of vertical and horizontal displacements and vertical accelerations,was recorded.The sampling rate was 200Hz,and recording started before the locomotive had reached the bridge and continued for a while after it has passed above the structure.

4.Results of static test

The static response of Bridge Km-23,in terms of vertical de?ection of the northern span,is shown in Fig.4.Two curves,for two sides of the crack at the crown,show little di?erences and indicate a relatively symmetric behavior for the arch.The curves show a relatively proportional load–deformation relationship and a relatively sti?response,from the beginning up to a load level of about 6000kN.At this stage,slope of the curve declines and large deformation begins,such that a yield limit may be assumed.Field observations showed that under increasing load,and before yielding,hair cracks appeared gradually at the construction joints and around initial cracks.The cracks became visible at a load level of about 4000kN and became wider and deeper by increase of load.The response of the bridge was not a?ected by initial cracks,and despite initiation of many cracks,the behavior remained relatively sti?

and strong up to the yield limit when de?ection was only 11mm.

Variation of crack width,at the crown,was measured by a horizontal LVDT and was drawn in Fig.5.It is seen that widening of the crack has started from the beginning and has continued to the end of the test.The curve shows that the rate of crack widening has in-creased at a load level of about 6000kN,almost at the same time when vertical de?ection started to yield.This indicates that yielding of the structure,in both hori-zontal and vertical directions,started simultaneously.Over the post-yield range,that started at 6000kN and continued to the ?nal stage,the response was ac-companied by severe cracking at the construction joints,crown,both ends of the arch,and around initial cracks.The crack pattern was the same as that of before yield,but cracks became much deeper and wider.The crack patterns,before and after the test,are shown in Fig.6.In this ?gure,the cracks that existed before the test are marked by i .In addition to initial cracks,vertical gaps between the construction gaps,are also shown.It is

seen that the pattern of cracking,during the test,was

Fig.3.Static loading of Bridge Km-23.

M.-S.Marefat et al./Construction and Building Materials 18(2004)661–667

663

determined by geometry of the construction joints and location of initial cracks.

During the test,only the northern span was loaded. But,cracks appeared on both spans according to Fig.6. The two spans interacted through the shared foundation and pavement.Cracking was recognized as the essential cause for yielding,since stress levels remained relatively small up to the?nal stage.

The cracks in Fig.6extend through di?erent layers including the arch,spandrel wall,concrete?ll,and pavement layer.The performance of the bridge showed that all the existing parts,i.e.,the arch,spandrel wall,?ll layer,pier,foundation,and even the ballast layer,in-teracted to the structural response and contributed to the load carrying capacity.Consideration of the strength,sti?ness,and cracks showed that the bridge acted like a multilayer continuous structure rather than an arch form.It was also observed that despite initiation of enormous cracks,the structural resistance continued to rise,throughout the test.Severe cracking in critical sections only caused a redistribution of the load to occur

and a change in the path of force to happen but did not cause any failure mechanism to take shape.

Tests on concrete cores indicated that depth of car-bonation in the arch was more than50mm.But,car-bonation did not ruin the structural strength because of lack of reinforcement in concrete.Bridge Km-23,at the current conditions,experiences a maximum static load of1200kN(a1200-kN6-axle locomotive).If this load is compared with the yield limit,a large strength reserve and a high safety margin may be envisaged.In total,the static test indicated that structural damage,time de-pendent e?ects,and environmental attack have not caused any signi?cant decline in the safety of the plain concrete bridge for expected service load.

5.Results of dynamic test

In the dynamic test,a1200-kN6-axle locomotive passed above the bridge at speeds of10,20,40,60and 80km/h.Fig.7shows variation of vertical de?ection for a speed of60km/h,recorded at the crown of Bridge Km-23.The curve starts with sagging de?ections and reaches two relatively large peaks under front and rear bogies of the locomotive.When the locomotive reaches the next span,upward de?ection starts and two rela-tively small peaks form.Immediately after the load has passed the next span,a sharp decrease of amplitude and a smooth response of the structure are observed.Fast ?uctuation,under dynamic force,and rapid decay of amplitude,immediately after passing of the locomotive, indicates the existence of a relatively large energy ab-sorption capacity and lack of any resonance e?ects.

Fig.8shows variation of vertical acceleration of Bridge Km-23,at the crown,under moving load.It may be observed that,when the load reaches the northern span,fast?uctuation with relatively large amplitude occurs.As the locomotive reaches the next span,the amplitude decreases sharply.Fluctuations disappear very soon when the load passes the bridge.Such char-acteristic was observed in all dynamic tests and indicated a convenient performance under moving locomotive.

existed before the test.

-3

-2.5

-2

-1.5

-1

-0.5

0.5

1

1.5

0.0 1.0 2.0 3.0 4.0 5.0 6.0

Time (second) V

e

r

t

i

c

a

l

D

i

s

p

l

a

c

e

m

e

n

t

(

m

i

l

l

i

m

e

t

e

r

)

Finite Element

Experiment

Fig.7.Dynamic response of Bridge Km-23,at the crown,for a speed of60km/h.

664M.-S.Marefat et al./Construction and Building Materials18(2004)661–667

This may be described,mainly,by relatively large mass and high sti?ness of the structure,and contribution of ?ll material and ballast layer to the dynamic response.In the dynamic test only the output signals were re-corded.For system identi?cation from output mea-surements,‘‘cross-spectral density functions’’[13]were calculated for two accelerometers at the crown.The normalized results were averaged over di?erent speeds.The analyses indicated a value of 10.9Hz for the ?rst natural frequency of the structure.Fig.9shows varia-tion of cross-spectral density function of Bridge Km-23.In the dynamic test,the impact factor was also de-termined.This factor depends on the free length of span,type of structural system,material properties,support conditions,load characteristics,and nature of the re-sponse.An important consideration is de?nition of the impact factor.It was de?ned on the basis of vertical displacement at the crown,that is,maximum displace-ments at di?erent speeds were divided by the maximum displacement of 10km/h.The results are depicted in

Fig.10.This ?gure shows that the impact factor,gen-erally,increases with speed,and suggests a value of 1.20,for speeds up to 80km/h.The suggested value may be compared with the recommendations made by UIC 776-1[14],EUROCODE 1[15],and AREMA [16].The ?rst two references recommend a value of 1.46and the third one recommends 1.29.It may be observed that the ?rst two references are relatively conservative while the third one is close to the test results.

6.Numerical modeling and load rating

The bridge exhibited relatively high structural re-dundancy and performed like a multi-layered continu-ous structure rather than an arch form.For numerical modeling,two dimensional ?nite element method was used.All parts of the bridge including the arch,pier,foundation,soil,spandrel wall,?ll material,and ballast layer were represented by plain stress elements.Initial cracks were carefully recorded and modeled as void spaces.A layer of soil of 10-m thickness,below the foundation,was taken into account.It was seen that appropriate representation of the cracks and soil layer signi?cantly in?uenced convergence of the model.

In numerical modeling,both of the static and dy-namic loads were simulated.The static load comprised a uniformly distributed load that was increased in suc-cessive steps according to the tests.The dynamic load was modeled by six point forces,with patterns and magnitudes similar to six axles of the locomotive.The point forces were moved along the bridge at time steps corresponding to speeds of the locomotive.The nu-merical simulation was restricted to pre-yield range of the response.Vertical displacement at the crown was chosen as calibration criterion.Modulus of elasticity of ballast,in?ll,arch,and soil were used as adaptive pa-rameters.An almost close coincidence between the cal-ibrated and measured curves was obtained,as is

shown

M.-S.Marefat et al./Construction and Building Materials 18(2004)661–667665

in Fig.7.The calibrated model was used for load rating considerations.

The main aim of the tests was to obtain a realistic estimate of the residual strength of the bridge.Field observations showed that despite formation of severe cracks at critical sections of the arch,the system man-aged to redistribute the load to other parts,and the strength continued to rise.This?nding formed a basis for load rating of the overall system.To assess the re-maining strength of the bridge,a factor of load rating was determined.The factor is usually de?ned as the ratio between live load capacity and live load demand. Based on stress design formula,the following equation was used:

RF?r allàr DL

dár LL

;e1T

where di?erent parameters in the equation were:RF, load rating factor;r all,admissible stress of material, based on code recommendations and test on concrete cores;r DL,stress caused by dead load,calculated by calibrated numerical model;r LL,stress caused by stan-dard live load,calculated by calibrated numerical model;d,impact factor,determined by experiment.

For live load,a standard pattern of25-ton axle load, according to UIC-776-1,was used.An important con-sideration was de?nition of an appropriate limit state. For reinforced concrete members,it is usual to de?ne the maximum?exural stress as a limit state.But in concrete masonry arch,?exural stresses are not large and reinforcement does not exist.In addition,tensile cracks appear too early.The tests indicated that under load levels much greater than the service load,even after severe cracking and considerable decline in sti?ness,the structural resistance continued to rise and the value of deformations remained small.Therefore,cracking and tensile stresses were not referenced.Another limit state was the maximum compressive stress in the https://www.wendangku.net/doc/6715818376.html,ing this criterion,a value of 1.4was calculated.If the maximum admissible de?ection were assumed as a limit state,the load-rating factor would exceed a value of10. In total,load-rating considerations showed that the bridge still enjoyed enough strength and safe perfor-mance under increasing load demand.

7.Summary and conclusions

In an experimental program,the remaining load carrying capacity of a plain concrete arch bridge was studied.The experiments included both dynamic and static test,and taking concrete cores from di?erent layers.A number of important conclusions are listed below:

?The test showed that all parts of the arch bridge such as arch,spandrel wall,?ll layer,pier,foundation,and

ballast layer contributed to the structural resistance.

The structural performance and crack patterns indi-cated that the masonry bridge acted like a continuous multi-layered structure rather than an arch form.?Despite relatively wide and deep cracks at critical sec-tions,that existed before the test,and severe cracking of the structure,that happened during the test,the re-sponse remained relatively strong and sti?up to load levels much greater than the expected service load.?Long-term environmental damage in the main arch, caused by carbonation,did not cause any serious structural problems because of lack of reinforcement in concrete.

?The dynamic response was relatively smooth and convenient,under moving locomotive.The bridge demonstrated a relatively large energy absorption ca-pacity and lack of any resonance e?ects.

?Two-dimensional modeling of the structure and geo-metric representation of the cracks resulted in a satis-factory results.Careful modeling of the cracks and taking into account the soil e?ect were two essential factors in convergence of the simulation.

Overall,the plain concrete arch bridge showed a safe and convenient performance under train loading,de-spite severe cracking at critical sections,carbonation of concrete,and aging of the structure. Acknowledgements

This paper is prepared on the basis of a research project that was carried out jointly by the University of Tehran,Deputy of Research project No.614/4/883, Faculty of Engineering,Structural Laboratory and the Research Center of the I.R.of Iran Railway.The au-thors thank those institutions for their support and funding of the project.

References

[1]Bensalem A,Fair?eld CA,Sibbald A.Non-destructive evaluation

of the dynamic response of a brickwork arch.Proc Institut Civil Eng Struct Build1997;122(1):69–82.

[2]Chatterjee PK,Datta TK.Dynamic analysis of arch bridges under

traveling loads.Int J Solid Struct1995;32(11):1585–94.

[3]Fanning PJ,Boothby TE.Three-dimensional modeling and full-

scale testing of stone arch https://www.wendangku.net/doc/6715818376.html,put Struct2001;79:2645–

62.

[4]Fanning PJ,Boothby TE,Roberts BJ.Longitudinal and trans-

verse e?ects in masonry arch assessment.Construct Build Mater 2001;15(1):51–60.

[5]Hughes TG,Blackler MJ.A review of the UK masonry arch

assessment methods.Proc Institut Civil Eng Struct Build 1997;122(3):305–15.

[6]La?ranchi M,Marti P.Robert Maillart’s curved concrete arch

bridges.J Struct Eng ASCE1997;123(10):1280–6.

[7]Lemmon C,Woolfenden PA.Developments in the analysis,

testing,and damage assessment of railway bridges.Proc Institut Civil Eng Transport1993;100(4):195–202.

666M.-S.Marefat et al./Construction and Building Materials18(2004)661–667

[8]Melbourne C,Gilbrt M.The behaviour of multiring brickwork

arch bridges.Struct Eng1995;73(3).

[9]Ponniah DA,Prentice DJ.Load carrying capacity of masonry

arch bridges estimated from multi-span model tests.Proc Instit Civil Eng Struct Build1998;128(1):81–90.

[10]Thavalingam A,Bicanic N,Robonson JI,Ponniah https://www.wendangku.net/doc/6715818376.html,pu-

tational framework for discontinuous modelling of masonry arch https://www.wendangku.net/doc/6715818376.html,put Struct2001;79(19):1821–30.

[11]Marefat MS,Ghahremani-Gargary E,Nadery R.Full-scale test

of a60-year-old mass concrete arch bridge.Koln,Germany, World Congress on Railway Research,25–29November;

2001.[12]Marefat MS,Ataee S.Field test of a20-m span unreiforced arch

bridge.In:Proceedings of the sixth international conference on short and medium span bridges,Canada,Vancouver,BC,July31–August2;2002.p.1287–95.

[13]Bendat JS,Piersol AG.Engineering application of correlation and

spectral analysis.2nd ed.New York:Wiley;1993.

[14]UIC776-1.Loads to be considered in railway design.4th ed.;

1994.

[15]EUROCODE1.Actions on structures,Part2:Tra?c loads on

bridges.prEN1991–1992;2001.

[16]American Railway Engineering and Maintenance of Way Associ-

ation.Manual For Railway Engineering;2002.

M.-S.Marefat et al./Construction and Building Materials18(2004)661–667667

统计学英语词汇

统计学英语词汇 发布: 2008-10-08 23:42 | 作者: zhou_209 | 来源: 6sigma品质网 统计学的一些英语词汇,希望对大家有用. A abscissa 横坐标 absence rate 缺勤率 absolute number 绝对数 absolute value 绝对值 accident error 偶然误差 accumulated frequency 累积频数 alternative hypothesis 备择假设 analysis of data 分析资料 analysis of variance(ANOVA) 方差分析 arith-log paper 算术对数纸 arithmetic mean 算术均数 assumed mean 假定均数 arithmetic weighted mean 加权算术均数 asymmetry coefficient 偏度系数 average 平均数 average deviation 平均差 B bar chart 直条图、条图 bias 偏性 binomial distribution 二项分布 biometrics 生物统计学 bivariate normal population 双变量正态总体 C cartogram 统计图

case fatality rate(or case mortality) 病死率 census 普查 chi-sguare(X2) test 卡方检验 central tendency 集中趋势 class interval 组距 classification 分组、分类 cluster sampling 整群抽样 coefficient of correlation 相关系数 coefficient of regression 回归系数 coefficient of variability(or coefficieut of variation) 变异系数collection of data 收集资料 column 列(栏) combinative table 组合表 combined standard deviation 合并标准差 combined variance(or poolled variance) 合并方差complete survey 全面调查 completely correlation 完全相关 completely random design 完全随机设计 confidence interval 可信区间,置信区间 confidence level 可信水平,置信水平 confidence limit 可信限,置信限 constituent ratio 构成比,结构相对数 continuity 连续性 control 对照 control group 对照组 coordinate 坐标 correction for continuity 连续性校正 correction for grouping 归组校正 correction number 校正数 correction value 校正值 correlation 相关,联系 correlation analysis 相关分析 correlation coefficient 相关系数 critical value 临界值 cumulative frequency 累积频率

《机械工程专业英语教程》课文翻译

Lesson 1 力学的基本概念 1、词汇: statics [st?tiks] 静力学;dynamics动力学;constraint约束;magnetic [m?ɡ'netik]有磁性的;external [eks't?:nl] 外面的, 外部的;meshing啮合;follower从动件;magnitude ['m?ɡnitju:d] 大小;intensity强度,应力;non-coincident [k?u'insid?nt]不重合;parallel ['p?r?lel]平行;intuitive 直观的;substance物质;proportional [pr?'p?:??n?l]比例的;resist抵抗,对抗;celestial [si'lestj?l]天空的;product乘积;particle质点;elastic [i'l?stik]弹性;deformed变形的;strain拉力;uniform全都相同的;velocity[vi'l?siti]速度;scalar['skeil?]标量;vector['vekt?]矢量;displacement代替;momentum [m?u'ment?m]动量; 2、词组 make up of由……组成;if not要不,不然;even through即使,纵然; Lesson 2 力和力的作用效果 1、词汇: machine 机器;mechanism机构;movable活动的;given 规定的,给定的,已知的;perform执行;application 施用;produce引起,导致;stress压力;applied施加的;individual单独的;muscular ['m?skjul?]]力臂;gravity[ɡr?vti]重力;stretch伸展,拉紧,延伸;tensile[tensail]拉力;tension张力,拉力;squeeze挤;compressive 有压力的,压缩的;torsional扭转的;torque转矩;twist扭,转动;molecule [m likju:l]分子的;slide滑动; 滑行;slip滑,溜;one another 互相;shear剪切;independently独立地,自立地;beam梁;compress压;revolve (使)旋转;exert [iɡ'z?:t]用力,尽力,运用,发挥,施加;principle原则, 原理,准则,规范;spin使…旋转;screw螺丝钉;thread螺纹; 2、词组 a number of 许多;deal with 涉及,处理;result from由什么引起;prevent from阻止,防止;tends to 朝某个方向;in combination结合;fly apart飞散; 3、译文: 任何机器或机构的研究表明每一种机构都是由许多可动的零件组成。这些零件从规定的运动转变到期望的运动。另一方面,这些机器完成工作。当由施力引起的运动时,机器就开始工作了。所以,力和机器的研究涉及在一个物体上的力和力的作用效果。 力是推力或者拉力。力的作用效果要么是改变物体的形状或者运动,要么阻止其他的力发生改变。每一种

英语原文及其翻译

Exploring Filipino School Counselors’ Beliefs about Learning Allan B. I. Bernardo [Abstract] School reform efforts that focus on student learning require school counselors to take on important new roles as advocates of student learning and achievement.But how do school counselors understand the process of learning? In this study, we explore the learning beliefs of 115 Filipino school counselors who indicated their degree of agreementwith 42 statements about the process of learning and the factors thatinfluence this process.A principal components analysis of the responses to the 42 statements suggested three factors:(F1)social-cognitive constructivist beliefs, (F2) teacher-curriculum-centered behaviorist beliefs,and (F3) individual difference factors.The preliminary results are briefly discussed in terms of issues related to how Filipino school counselors’ conceptions of learning may guide their strategies for promoting student learning and achievement. [Key words]beliefs about learning, conceptions of learning, school counselors, student learning, Philippines School reform efforts in different parts of the world have focusedon students’learning. In particular,most school improvement programsnow aim to ensure that students acquire the high-level knowledge and skills that help them to thrive in today’s highly competitive globaleconomy (e.g., Lee & Williams, 2006). I n this regard, school reform programs draw from various contemporary theories and research on learning (e.g.,Bransford,Brown, & Cocking, 1999; Lambert & McCombs, 1998).The basic idea is that all school improvement efforts should be directed at ensuring students achieve high levels of learning or attainment of well-defined curricular objectives and standards.For example, textbooks (Chien & Young, 2007), computers and educational technology (Gravoso, 2002; Haertnel & Means, 2003;Technology in Schools Task Force, 2003), and educational assessment systems (Black & Wiliam2004; Cheung & Ng, 2007; Clark, 2001; Stiggins, 2005) are being reconsidered as regards how they can effectively provide scaffolds and resources for advancing student learning. Likewise,the allocation and management of a school’s financial resources are assessed in terms ofwhether these are effectively mobilized and utilized towards improving student learning (Bolam, 2006; Chung & Hung, 2006; Retna, 2007). In this regard, some advocates have also called for an examination of the role of school counselors in these reform efforts (Herr, 2002). Inthe United States, House and Hayes (2002) challenged school counselors to take proactive leadership roles in advocating for the success of all

机械专业术语英文翻译

陶瓷 ceramics 合成纤维 synthetic fibre 电化学腐蚀 electrochemical corrosion 车架 automotive chassis 悬架 suspension 转向器 redirector 变速器 speed changer 板料冲压 sheet metal parts 孔加工 spot facing machining 车间 workshop 工程技术人员 engineer 气动夹紧 pneuma lock 数学模型 mathematical model 画法几何 descriptive geometry 机械制图 Mechanical drawing 投影 projection 视图 view 剖视图 profile chart 标准件 standard component 零件图 part drawing 装配图 assembly drawing 尺寸标注 size marking

技术要求 technical requirements 刚度 rigidity 内力 internal force 位移 displacement 截面 section 疲劳极限 fatigue limit 断裂 fracture 塑性变形 plastic distortion 脆性材料 brittleness material 刚度准则 rigidity criterion 垫圈 washer 垫片 spacer 直齿圆柱齿轮 straight toothed spur gear 斜齿圆柱齿轮 helical-spur gear 直齿锥齿轮 straight bevel gear 运动简图 kinematic sketch 齿轮齿条 pinion and rack 蜗杆蜗轮 worm and worm gear 虚约束 passive constraint 曲柄 crank 摇杆 racker 凸轮 cams

机械专业外文翻译(中英文翻译)

外文翻译 英文原文 Belt Conveying Systems Development of driving system Among the methods of material conveying employed,belt conveyors play a very important part in the reliable carrying of material over long distances at competitive cost.Conveyor systems have become larger and more complex and drive systems have also been going through a process of evolution and will continue to do so.Nowadays,bigger belts require more power and have brought the need for larger individual drives as well as multiple drives such as 3 drives of 750 kW for one belt(this is the case for the conveyor drives in Chengzhuang Mine).The ability to control drive acceleration torque is critical to belt conveyors’performance.An efficient drive system should be able to provide smooth,soft starts while maintaining belt tensions within the specified safe limits.For load sharing on multiple drives.torque and speed control are also important considerations in the drive system’s design. Due to the advances in conveyor drive control technology,at present many more reliable.Cost-effective and performance-driven conveyor drive systems covering a wide range of power are available for customers’ choices[1]. 1 Analysis on conveyor drive technologies 1.1 Direct drives Full-voltage starters.With a full-voltage starter design,the conveyor head shaft is direct-coupled to the motor through the gear drive.Direct full-voltage starters are adequate for relatively low-power, simple-profile conveyors.With direct fu11-voltage starters.no control is provided for various conveyor loads and.depending on the ratio between fu11-and no-1oad power requirements,empty starting times can be three or four times faster than full load.The maintenance-free starting system is simple,low-cost and very reliable.However, they cannot control starting torque and maximum stall torque;therefore.they are

英语原文及翻译

高速视频处理系统中的信号完整性分析 摘要:结合高速DSP图像处理系统讨论了高速数字电路中的信号完整性问题,分析了系统中信号反射、串扰、地弹等现象破坏信号完整性的原因,通过先进IS工具的辅助设计,找出了确保系统信号完整性的具体方法。 关键词:高速电路设计信号完整性 DSP系统 深亚微米工艺在IC设计中的使用使得芯片的集成规模更大、体积越来越小、引脚数越来越多;由于近年来IC工艺的发展,使得其速度越来越高。从而,使得信号完整性问题引起电子设计者广泛关注。 在视频处理系统中,多维并行输入输出信号的频率一般都在百兆赫兹以上,而且对时序的要求也非常严格。本文以DSP图像处理系统为背景,对信号完整性进行准确的理论分析,对信号完整性涉及的典型问题[1]——不确定状态、传输线效应、反射、串扰、地弹等进行深入研究,并且从实际系统入手,利用IS仿真软件寻找有效的途径,解决系统的信号完整性问题。 1 系统简介 为了提高算法效率,实时处理图像信息,本图像处理系统是基于DSP+FPGA结构设计的。系统由SAA7111A视频解码器、TI公司的TMS320C6701 DSP、Altera公司的EPlK50QC208 FPGA、PCI9054 PCI接口控制器以及SBRAM、SDRAM、FIFO、FLASH等构成。FPGA是整个系统的时序控制中心和数据交换的桥梁,而且能够对图像数据实现快速底层处理。DSP是整个系统实时处理高级算法的核心器件。系统结构框图如图1所示。 在整个系统中,PCB电路板的面积仅为15cm×l5cm,系统时钟频率高达167MHz,时钟沿时间为0.6ns。由于系统具有快斜率瞬变和极高的工作频率以及很大的电路密度,使得如何处理高速信号问题成为一个制约设计成功的关键因素。 2 系统中信号完整性问题及解决方案 2.1 信号完整性问题产生机理 信号的完整性是指信号通过物理电路传输后,信号接收端看到的波形与信号发送端发送的波形在容许的误差范围内保持一致,并且空间邻近的传输信号间的相互影响也在容许的范围之内。因此,信号完整性分析的主要目标是保证高速数字信号可靠的传输。实际信号总是存在电压的波动,如图2所示。在A、B两点由于过冲和振铃[2]的存在使信号振幅落入阴影部分的不确定区,可能会导致错误的逻辑电平发生。总线信号传输的情况更加复杂,任何一个信号发生相位上的超前或滞后都可能使总线上数据出错,如图3所示。图中,CLK为时钟信号,D0、D1、D2、D3是数据总线上的信号,系统允许信号最大的建立时间[1]为△t。在正常情况下,D0、D1、D2、D3信号建立时间△t1<△t,在△t时刻之后数据总线的数据已稳定,系统可以从总线上采样到正确的数据,如图3(a)所示。相反,当信号D1、D2、D3受过冲和振铃等信号完整问题干扰时,总线信号就发生

(机械制造行业)机械英文翻译

英文翻译 机械设计 一台完整机器的设计是一个复杂的过程。机械设计是一项创造性的工作。设计工程师不仅在工作上要有创造性,还必须在机械制图、运动学、工程材料、材料力学和机械制造工艺学等方面具有深厚的基础知识。 Machine Design The complete design of a machine is a complex process. The machine design is a creative work. Project engineer not only must have the creativity in the work, but also must in aspect and so on mechanical drawing, kinematics, engineerig material, materials mechanics and machine manufacture technology has the deep elementary knowledge. 任何产品在设计时第一步就是选择产品每个部分的构成材料。许多的材料被今天的设计师所使用。对产品的功能,它的外观、材料的成本、制造的成本作出必要的选择是十分重要的。对材料的特性必须事先作出仔细的评估。 One of the first steps in the design of any product is to select the material from which each part is to be made. Numerous materials are available to today's designers. The function of the product, its appearance, the cost of the material, and the cost of fabrication are important in making a selection. A careful evaluation of the properties of a. material must be made prior to any calculations. 仔细精确的计算是必要的,以确保设计的有效性。在任何失败的情况下,最好知道在最初设计中有有缺陷的部件。计算(图纸尺寸)检查是非常重要的。一个小数点的位置放错,就可以导致一个本可以完成的项目失败。设计工作的各个方面都应该检查和复查。 Careful calculations are necessary to ensure the validity of a design. In case of any part failures, it is desirable to know what was done in originally designing the defective components. The checking of calculations (and drawing dimensions) is of utmost importance. The misplacement of one decimal point can ruin an otherwise acceptable project. All aspects of design work should be checked and rechecked. 计算机是一种工具,它能够帮助机械设计师减轻繁琐的计算,并对现有数据提供进一步的分析。互动系统基于计算机的能力,已经使计算机辅助设计(CAD)和计算机辅助制造(CAM)成为了可能。心理学家经常谈论如何使人们适应他们所操作的机器。设计人员的基本职责是努力使机器来适应人们。这并不是一项容易的工作,因为实际上并不存在着一个对所有人来说都是最优的操作范围和操作

统计学专业英语翻译

汉译英 Population 总体,样本总体sample 样本,标本parameter 限制因素 median 中位数odd 奇数,单数even 偶数 range 极差variance 方差standard deviation 标准差Covariance 协方差empty event 空事件product event 积事件 conditional probability 条件概率Random variable 随机变量binominal distribution 二项式分布uniform distribution 均匀分布Poisson distribution 泊松分布residual 残差 central limit theorem 中心极限定律 英译汉 descriptive statistics 描述统计学mathematical statistics 数理统计学inductive statistics 归纳统计学Inferential statistics 推断统计学dimension 维,维数continuous variable 连续变量ordinal variable 有序变量nominal variable 名义变量dichotomous 两分的;二歧的discrete variable 离散变量categorical variable 分类变量location 定位,位置,场所dispersion 分散mean 均值unimodal单峰的 multimodal 多峰的chaotic 无秩序的grouped data 分组数据 frequency distribution频数分布cumulative frequency 累加频数tallying 计算 Uniformly distribution 均匀分布histogram 直方图frequency polygon 频率多边图rectangle 矩形Percentile 百分位数quartile 四分位数 interquartile range 四分位数间距simple event 简单事件Compound event 复合事件mutually exclusive 互斥的,互补相交的complementary event 对立事件Independent 独立的joint probability function 联合概率函数jacobian雅克比行列式 Law of large numbers大数定律point estimate 点估计estimate 估计值 statistic 统计量optimality 最优性Unbiased estimate 无偏估计量efficient estimate 有偏估计量unbiasedness无偏性efficience有效性Consistent estimate 一致估计量 asymptotic properties 渐近性质Confidence interval 置信区间interval estimation 区间估计 null hypothesis 原假设alternative hypothesis 备择假设significance level 显著性水平power function 幂函数testing procedures 检验方法test statistic 检验统计量 rejection region 拒绝区域acceptance region 接受区域critical region 临界区域 first-derivatives 一阶导数second-derivatives 二阶导数Likelihood ratio 似然比dependent variable因变量unexplanatory variable未解释变量independent variable自变量 Error term 误差项regression coefficients 回归系数Sum of squared residuals 残差平方和Marginal probability function 边际概率函数joint probability density function 联合概率密度函数Marginal probability density function边际概率密度函数stochastically independent 随机独立的 Mutually independently distribution 相互独立的分布independently and identically distribution 独立同分布的likelihood function 似然函数maximum likelihood estimator 最大似然估计量 maximum likelihood estimate 最大似然估计值log-likelihood function 对数似然函数 ordinary least squares estimation/estimate/estimator 普通最小二乘估计/估计值/估计量 linear unbiased estimator 线性无偏估计

机械专业英文翻译

启动轴starting axle 启动齿轮starting gear 启动棘轮starting ratchet wheel 复位弹簧restoring, pull back spring 弹簧座spring seating 摩擦簧friction spring 推力垫圈thrust washer 轴挡圈axle bumper ring 下料filling 切断cut 滚齿机gear-hobbing machine 剪料机material-shearing machine 车床lathe 拉床broaching machine 垂直度verticality, vertical extent 平行度 parallelism同心度 homocentricity 位置度position 拉伤pulling damage 碰伤bumping damage 缺陷deficiency 严重缺陷severe deficiency 摩擦力friction 扭距twist 滑动glide 滚动roll 打滑skid 脱不开can’t seperate 不复位can’t restore 直径diameter M值= 跨棒距test rod span 公法线common normal line 弹性elasticity 频率特性frequency characteristic 误差error 响应response 定位allocation 机床夹具jig 动力学dynamic 运动学kinematic 静力学static 分析力学analyse mechanics 拉伸pulling 压缩hitting 机床machine tool 刀具cutter 摩擦friction 联结link 传动drive/transmission 轴shaft 剪切shear 扭转twist 弯曲应力bending stress 三相交流电three-phase AC 磁路magnetic circles 变压器transformer 异步电动机asynchronous motor 几何形状geometrical 精度precision 正弦形的sinusoid 交流电路AC circuit 机械加工余量machining allowance 变形力deforming force 变形deformation 电路circuit 半导体元件semiconductor element 拉孔broaching 装配assembling 加工machining 液压hydraulic pressure 切线tangent 机电一体化mechanotronics mechanical-electrical integration 稳定性stability 介质medium 液压驱动泵fluid clutch 液压泵hydraulic pump 阀门valve 失效invalidation 强度intensity 载荷load 应力stress 安全系数safty factor 可靠性reliability 螺纹thread 螺旋helix 键spline 销pin 滚动轴承rolling bearing 滑动轴承sliding bearing 弹簧spring 制动器arrester brake 十字结联轴节crosshead 联轴器coupling 链chain 皮带strap 精加工finish machining 粗加工rough machining 变速箱体gearbox casing 腐蚀rust 氧化oxidation 磨损wear 耐用度durability 机械制图 Mechanical drawing 投影projection 视图view 剖视图profile chart 标准件standard component 零件图part drawing 装配图assembly drawing 尺寸标注size marking 技术要求 technical requirements 刚度rigidity 内力internal force 位移displacement 截面section 疲劳极限fatigue limit 断裂fracture 塑性变形plastic distortion 脆性材料brittleness material 刚度准则rigidity criterion 垫圈washer 垫片spacer 直齿圆柱齿轮 straight toothed spur gear 斜齿圆柱齿轮 helical-spur gear 直齿锥齿轮 straight bevel gear 运动简图kinematic sketch 齿轮齿条pinion and rack 蜗杆蜗轮worm and worm gear 虚约束passive constraint 曲柄crank 摇杆racker 凸轮cams 反馈feedback 发生器generator 直流电源DC electrical source 门电路gate circuit 外圆磨削external grinding 内圆磨削internal grinding 平面磨削plane grinding 变速箱gearbox 离合器clutch 绞孔fraising 绞刀reamer

英文翻译(原文)

GRA VITY RETAINING?WALL 1. INTRODUCTION Retaining walls are structures used to provide stability for earth or other material where conditions disallow the mass to assume its natural slope, and are commonly used to hold back or support soilbanks,coal or ore piles, and water. Retaining walls are classified, based on the method of achieving stability, into six principal types (Fig.1). The gravity-wall depends upon its weight, as the name implies, for stability. The cantilever wall is a reinforced-concrete wall that utilizes cantilever action to retain the mass behind the wall from assuming a natural slope. Stability of this wall is partially achieved from the weight of soil on the heel portion of the base slab. A counterfort retaining wall is similar to a cantilever retaining wall, except that it is used where the cantilever is long or for very high pressures behind wall and has counterforts, which tie the wall and base together, built at intervals along the wall to reduce the bending moments and sheers. As indicated in Fig.1c, the counterfort is behind the wall and subjected to tensile forces. A buttressed retaining wall is similar to a counterfort wall, except that the bracing is in front of the wall and is in compression instead of tension. Two other types of walls not considered further are crib walls, which are built-up members of pieces of precast concrete, metal, or timber and are supported by anchor pieces embedded in the soil for stability, and semigravity walls, which are walls intermediate between a true gravity and a cantilever wall. (a)(b)(e)

各专业的英文翻译剖析

哲学Philosophy 马克思主义哲学Philosophy of Marxism 中国哲学Chinese Philosophy 外国哲学Foreign Philosophies 逻辑学Logic 伦理学Ethics 美学Aesthetics 宗教学Science of Religion 科学技术哲学Philosophy of Science and Technology 经济学Economics 理论经济学Theoretical Economics 政治经济学Political Economy 经济思想史History of Economic Thought 经济史History of Economic 西方经济学Western Economics 世界经济World Economics 人口、资源与环境经济学Population, Resources and Environmental Economics 应用经济学Applied Economics 国民经济学National Economics 区域经济学Regional Economics 财政学(含税收学)Public Finance (including Taxation) 金融学(含保险学)Finance (including Insurance) 产业经济学Industrial Economics 国际贸易学International Trade 劳动经济学Labor Economics 统计学Statistics 数量经济学Quantitative Economics 中文学科、专业名称英文学科、专业名称 国防经济学National Defense Economics 法学Law 法学Science of Law 法学理论Jurisprudence 法律史Legal History 宪法学与行政法学Constitutional Law and Administrative Law 刑法学Criminal Jurisprudence 民商法学(含劳动法学、社会保障法学) Civil Law and Commercial Law (including Science of Labour Law and Science of Social Security Law ) 诉讼法学Science of Procedure Laws

机械类英语论文及翻译翻译

High-speed milling High-speed machining is an advanced manufacturing technology, different from the traditional processing methods. The spindle speed, cutting feed rate, cutting a small amount of units within the time of removal of material has increased three to six times. With high efficiency, high precision and high quality surface as the basic characteristics of the automobile industry, aerospace, mold manufacturing and instrumentation industry, such as access to a wide range of applications, has made significant economic benefits, is the contemporary importance of advanced manufacturing technology. For a long time, people die on the processing has been using a grinding or milling EDM (EDM) processing, grinding, polishing methods. Although the high hardness of the EDM machine parts, but the lower the productivity of its application is limited. With the development of high-speed processing technology, used to replace high-speed cutting, grinding and polishing process to die processing has become possible. To shorten the processing cycle, processing and reliable quality assurance, lower processing costs. 1 One of the advantages of high-speed machining High-speed machining as a die-efficient manufacturing, high-quality, low power consumption in an advanced manufacturing technology. In conventional machining in a series of problems has plagued by high-speed machining of the application have been resolved. 1.1 Increase productivity High-speed cutting of the spindle speed, feed rate compared withtraditional machining, in the nature of the leap, the metal removal rate increased 30 percent to 40 percent, cutting force reduced by 30 percent, the cutting tool life increased by 70% . Hardened parts can be processed, a fixture in many parts to be completed rough, semi-finishing and fine, and all other processes, the complex can reach parts of the surface quality requirements, thus increasing the processing productivity and competitiveness of products in the market. 1.2 Improve processing accuracy and surface quality High-speed machines generally have high rigidity and precision, and other characteristics, processing, cutting the depth of small, fast and feed, cutting force low, the workpiece to reduce heat distortion, and high precision machining, surface roughness small. Milling will be no high-speed processing and milling marks the surface so that the parts greatly enhance the quality of the surface. Processing Aluminum when up Ra0.40.6um, pieces of steel processing at up to Ra0.2 ~ 0.4um.