Contractor Safety Manual 承包商安全手册英文版

Contractor Safety Manual

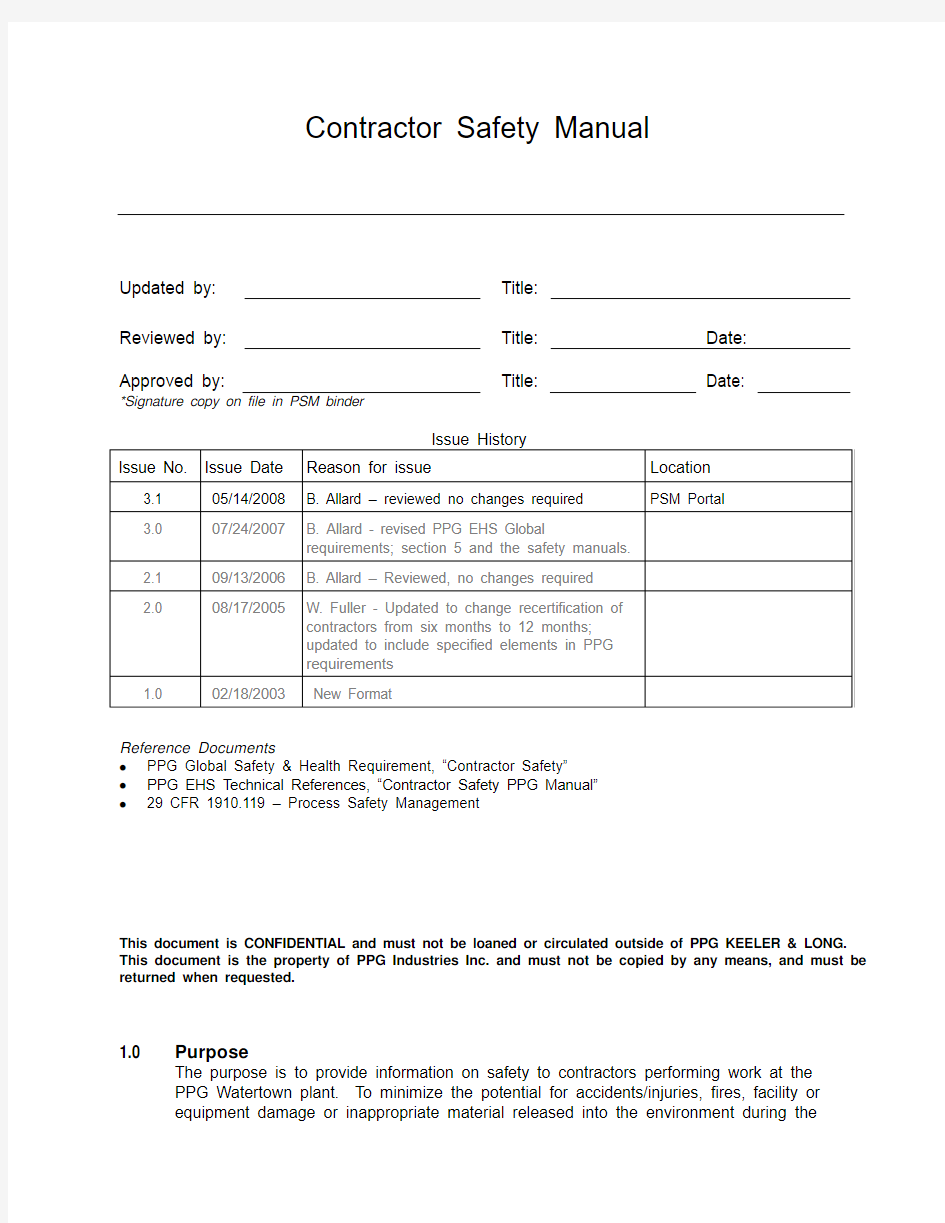

Updated by: Title:

Reviewed by: Title: Date: Approved by: Title: Date:

*Signature copy on file in PSM binder

Reference Documents

?PPG Global Safety & Health Requirement, “Contractor Safety”

?PPG EHS Technical References, “Contractor Safety PPG Manual”

?29 CFR 1910.119 – Process Safety Management

This document is CONFIDENTIAL and must not be loaned or circulated outside of PPG KEELER & LONG. This document is the property of PPG Industries Inc. and must not be copied by any means, and must be returned when requested.

1.0 Purpose

The purpose is to provide information on safety to contractors performing work at the PPG Watertown plant. To minimize the potential for accidents/injuries, fires, facility or equipment damage or inappropriate material released into the environment during the

performance of contractor work. These rules are to ensure contractor employees

understand and comply with them.

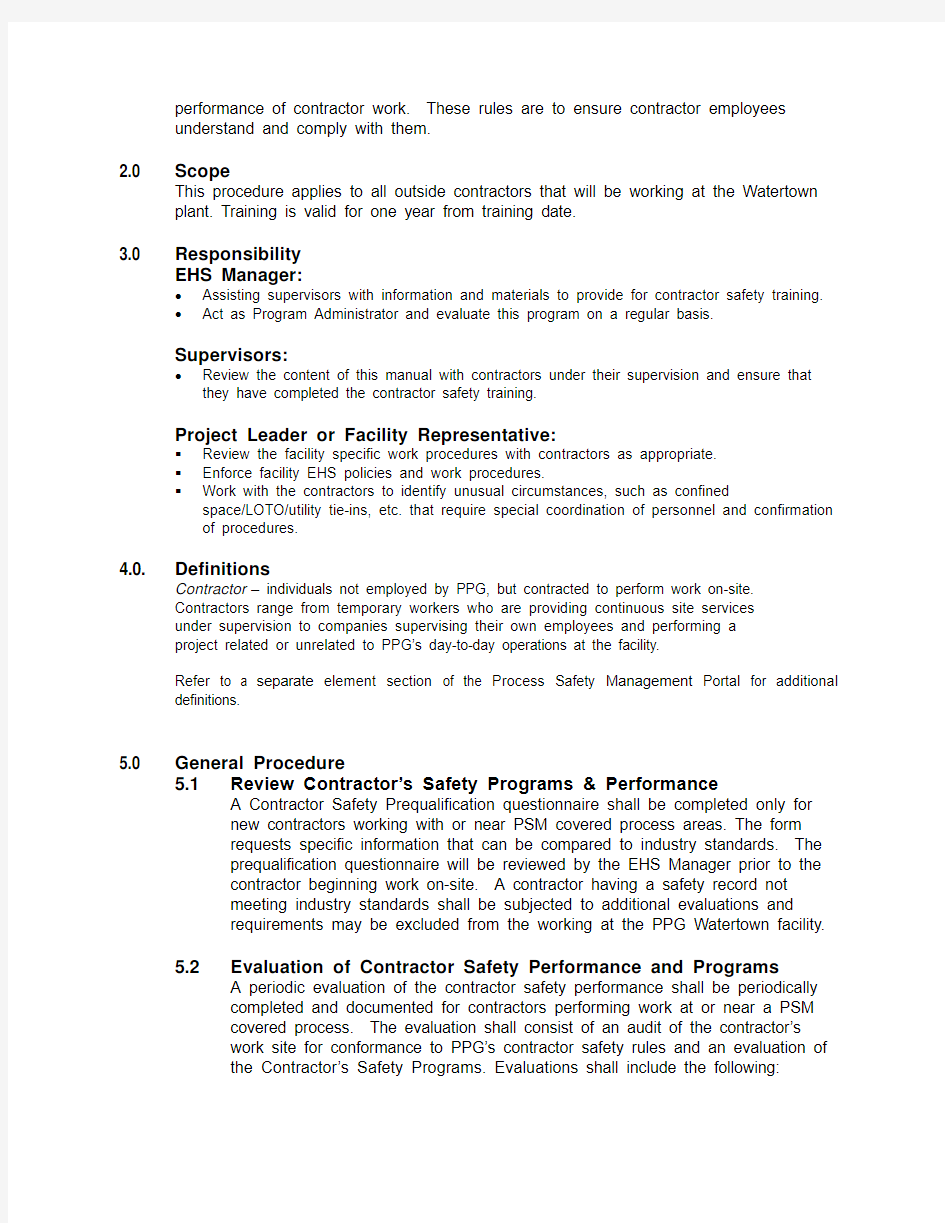

2.0 Scope

This procedure applies to all outside contractors that will be working at the Watertown

plant. Training is valid for one year from training date.

3.0 Responsibility

EHS Manager:

?Assisting supervisors with information and materials to provide for contractor safety training.

?Act as Program Administrator and evaluate this program on a regular basis.

Supervisors:

?Review the content of this manual with contractors under their supervision and ensure that they have completed the contractor safety training.

Project Leader or Facility Representative:

?Review the facility specific work procedures with contractors as appropriate.

?Enforce facility EHS policies and work procedures.

?Work with the contractors to identify unusual circumstances, such as confined

space/LOTO/utility tie-ins, etc. that require special coordination of personnel and confirmation

of procedures.

4.0. Definitions

Contractor– individuals not employed by PPG, but contracted to perform work on-site.

Contractors range from temporary workers who are providing continuous site services

under supervision to companies supervising their own employees and performing a

project related or unrelated to PPG’s day-to-day operations at the facility.

Refer to a separate element section of the Process Safety Management Portal for additional definitions.

5.0 General Procedure

5.1 Review Contractor’s Safety Programs & Performance

A Contractor Safety Prequalification questionnaire shall be completed only for

new contractors working with or near PSM covered process areas. The form

requests specific information that can be compared to industry standards. The

prequalification questionnaire will be reviewed by the EHS Manager prior to the

contractor beginning work on-site. A contractor having a safety record not

meeting industry standards shall be subjected to additional evaluations and

requirements may be excluded from the working at the PPG Watertown facility.

5.2 Evaluation of Contractor Safety Performance and Programs

A periodic evaluation of the contractor safety performance shall be periodically

completed and documented for contractors performing work at or near a PSM

covered process. The evaluation shall consist of an audit of the contractor’s

work site for conformance to PPG’s contractor safety rules and an evaluation of

the Contractor’s Safety Programs. Evaluat ions shall include the following:

a. Verification of the Contractor’s compliance with their own and PPG’s Safety

and Health Programs

b. Verification that the Contractor is in compliance with PPG’s Alcohol, Drugs

and Other Intoxicants policy.

c. Confirmation that t he Contractor’s Employees are properly trained and

qualified to perform the required work with supporting documentation

d. Contractor’s employees have been instructed in the known potential for fire,

explosion and toxic release hazards related to the work, including supporting documentation.

e. Contractor’s employees have been instructed in the applicable provisions of

the Emergency Action Plan, including supporting documentation.

f. The performance of the contractor in advising PPG of any unique hazards

presented b y, or discovered by the contractor’s work.

g. That the contractor documents all required training.

Evaluation of the Contractor Safety Program will be documented using the Contractor Periodic EHS Program Evaluation Survey.

Evaluation of the Contractor’s job site shall be documented using the Contractor Periodic Work Site Safety Survey

质量手册翻译中英文对照解析

质量手册翻译中英文术语表 3.1.1 质量 quality 3.1.2 要求 requirement 3.1.3 等级 grade 3.1.4 顾客满意 customer satisfaction 3.1.5 能力 capability 3.2.1 体系(系统) system 3.2.2 管理体系 management system 3.2.3 质量管理体系 quality management syste m 3.2.4 质量方针 quality policy 3.2.5 质量目标 quality objective 3.2.6 管理 management 3.2.7 最高管理者 top management 3.2.8 质量管理 quality management 3.2.9 质量策划 quality planning 3.2.10 质量控制 quality control 3.2.11 质量保证 quality assurance 3.2.12 质量改进 quality improvement 3.2.13 持续改进 continual improvement 3.2.14 有效性 effectiveness 3.2.15 效率 efficiency 3.3.1 组织 organization 3.3.2 组织结构 organizational structure 3.3.3 基础设施 infrastructure 3.3.4 工作环境 '77ork environment 3.3.5 顾客 customer 3.3.6 供方 supplier 3.3.7 相关方 interested party 3.4.1 过程 process 3.4.2 产品 product 3.4.3 项目 project 3.4.4 设计和开发 design and development 3.4.5 程序 procedure

ISO14001质量手册英文版模板(2008版)

ABC Farms ISO 14001 - Environmental Management System Manual Prepared By: Approved By: Signature: ____________________________ Date: _________ / Revision #: 0 / Revision Date: / Effective Date:

SECTION 0 - TABLE OF CONTENTS MANUAL ISO SECTION SECTION TITLE PAGE SECTION 0TABLE OF CONTENTS x SECTION I INTRODUCTION x SECTION II DISTRIBUTION, REVISION & CONTROL x 4.2 4.2ENVIRONMENTAL POLICY x 4.3 4.3PLANNING x 4.3.1 4.3.1 Environmental Aspects x 4.3.2 4.3.2 Legal and Other Requirements x 4.3.3 4.3.3 Objectives and Targets x 4.3.4 4.3.4 Environmental Management Programs x 4.4 4.4IMPLEMENTATION & OPERATION x 4.4.1 4.4.1 Structure and Responsibility x 4.4.2 4.4.2 Training, Awareness and Competence x 4.4.3 4.4.3 Communication x 4.4.4 4.4.4 Environmental Management System Documentation x 4.4.5 4.4.5 Document Control x 4.4.6 4.4.6 Operational Control x 4.4.7 4.4.7 Emergency Preparedness and Response x 4.5 4.5CHECKING AND CORRECTIVE ACTION x 4.5.1 4.5.1 Monitoring and Measurement x 4.5.2 4.5.2 Non-conformance and Corrective Action x 4.5.3 4.5.3 Records Management x 4.5.4 4.5.4 Environmental Management System Audits x 4.6 4.6MANAGEMENT REVIEW x

吉利供应商质量手册(第1版)

ID 号:33526871 受控文件 编制: 汪斌,叶雁飞;文控审核: 赵建岭;会签: 何伟,丁云长,崔载福,陈卫德,胡雄旺,徐华2,徐海波;意见汇总: 汪斌,赵建岭;审核: 徐华2;批准: 刘向阳;发布目标: 赵建岭 归档日期:2012-04-20 17:16:38 编码: GL 质量管理体系文件 文件名称 吉利供应商质量手册 版 本 1 页码 / 文件编号 GLW000864 生效日期 2012年4月23日

供应商质量手册 (第一版) 浙江吉利控股集团有限公司

前 言 《供应商质量手册》是参考吉利公司的质量管理手册、程序文件,并结合当前吉利供应商管理的现状而编制的,以指导供应商在准入、零部件开发、量产初期及批量生产管理等过程中的需要开展哪些工作及提交哪些文件。 当前,吉利在不断提升自身竞争能力的同时,努力打造具有“三高一低”(高质量、高技术、高忠诚度和低成本)的、一流竞争力的供应商体系。相信通过相互合作、沟通理解和及时采取措施将有利于吉利和供应商双方事业的发展,最终实现“让世界充满吉利”的美好愿景! 本手册版权属于浙江吉利控股集团有限公司及其各子公司。 未经吉利的书面许可,本手册的任何内容都不能以任何形式和手段进行复制、储存和传送。供应商不得以任何方式将本手册中提到的吉利品质体系内容提供给第三者。 本手册将在运用过程中不断更新完善,各供应商朋友如在应用过程中发现不足,请及时反馈指正。 如有任何问题,请与相关SQE联系。 吉利集团质量管理部 供应商管理室 2012年4月

目录 第一章 供应商选点 (4) 第二章 先期产品质量策划 (6) 第一节 第一阶段供应商品熟评价 (6) 第二节 第二阶段供应商品熟评价 (25) 第三节 第三阶段供应商品熟评价 (34) 第四节 第四阶段供应商品熟评价 (53) 第五节 第五阶段供应商品熟评价 (59) 第六节 生产件批准程序(PPAP) (61) 第三章 量产管理 (66) 第一节 驻厂检验 (66) 第二节 受控发运 (69) 第三节 统计技术 (71) 第四节 质量改进 (73) 第五节 供应商审核管理 (80) 第六节 免检管理 (81) 第七节 供应商优化管理 (82) 第八节 供应商违约管理 (83) 第四章 供应商品质五星级评价 (84)

常用英文手册

英文缩写展开及翻译的整理 日常使用类: KPI——Key Performance Indication关键业绩指标 DPI——Day Performance Indication日业绩指标 MIS——Management Information System信息管理系统CRC——Customer Record Card 客户销售记录 OJT——On Job Training市场协同作业 Back Check——市场查核 Routine Call——路线拜访 Price of——降价 Reference——参考 DMS——data management system数据管理系统 EDMS——electric data management system电子数据管理系统 Instant Noodles——即食面 Workshop——专题讨论会,研讨会 Total——总数;合计 Food——食品 Non-Food——非食品 Instant Noodles——速食面 AC-nielsen——市调数据 MAT——moving annual today 从当月回推一年 SMART原则——目标订定的原则S(Specific)具体的,明确的;M(Measurable)

可衡量的;A(Attainable);可达到的;R(Relevant)相关性;T(Time-based)明确的截止时间 PDCA——管理循环P(Plan)计划D(do)执行C(Check)检核A(Action)改善 职务名称类: SD——sales director 销售总监 SM——sales Manager 销售经理 SOM——Sales Operation Manager TM——trade marketing 通路企划 MOM——Marketing Operation Management (地方营运主管)MO——Marketing Operation 地方推广专员(以前的MS)BM——Brand Manager品牌经理(品牌主管)ABM——Assistance Product Manager助理品牌经理(产品人) 直营常用类: FMCG——fast moving consumer goods 快速消费品 Trading Term——商业合约 Monthly Rebate——月返:每月不因销售金额大小给与客户的无条件的返利折扣,通称月返 Data Sharing/Information Free——资讯费:因客户要求各项销售数据或订单传输及对账单等资料提供费,也称讯息费 New Store Open Free——新店开店赞助费 Incentive Rebate——年返:每年双方因销售目标金额大小给与客户的有条件返利,通称年返

ISO9001:2015全套文件英文版(含质量手册及全套程序文件)

Ningbo XXX Material Technology Co.,Ltd ISO9001:2015 Quality Manual Revision [A/0] - [2018/3/1] (c) [Copyright Year Of 2018] [Ningbo XXX Material Technology Co.,Ltd]; all rights reserved. This document may contain proprietary information and may only be released to third parties with approval of management. Document is uncontrolled unless otherwise marked; uncontrolled documents are not subject to update notification.

Revision [A/0] - [2018/3/1] Page 1 of 19 TABLE OF CONTENTS 0.0 Revision History and Approval ...................................................................................................................... 3 1.0 Welcome to Ningbo XXX Material Technology Co.,Ltd ................................................................................ 4 2.0 XXX Material: Who We Are ........................................................................................................................... 4 2.1 Determining Our Strategic Direction ......................................................................................................... 4 2.2 Scope of the Management System ........................................................................................................... 4 2.2.1 Scope Statement ............................................................................................................................... 4 2.2.2 Facilities Within the Scope ................................................................................................................ 4 2.2.3 Permissible Exclusions ..................................................................................................................... 5 2.2.4 Scope of the ISO9001:2015 Quality Manual ..................................................................................... 5 3.0 Quality Policy................................................................................................................................................. 5 4.0 Management System Structure and Controls ............................................................................................... 5 4.1 Process Approach .................................................................................................................................... 5 4.1.1 Process Identification ........................................................................................................................ 5 4.1.2 Process Controls & Objectives .......................................................................................................... 6 4.1.3 Outsourced Processes ...................................................................................................................... 7 4.2 Documentation & Records ....................................................................................................................... 7 4.2.1 General .............................................................................................................................................. 7 4.2.2 Control of Documents ....................................................................................................................... 7 4.2.3 Control of Records ............................................................................................................................ 7 4.3 Change Management ................................................................................................................................ 8 4.4 Risks and Opportunities ............................................................................................................................ 8 5.0 Management & Leadership ........................................................................................................................... 8 5.1 Management Leadership and Commitment .............................................................................................. 8 5.2 Customer Focus ........................................................................................................................................ 9 5.3 Quality Policy ............................................................................................................................................. 9 5.4 Organizational Roles Responsibilities & Authorities ................................................................................. 9 5.5 Internal Communication ............................................................................................................................ 9 5.6 Management Review .............................................................................................................................. 10 6.0 Resources ................................................................................................................................................... 10 6.1 Provision of Resources ........................................................................................................................... 10 6.2 Human Resources .................................................................................................................................. 10 6.3 Infrastructure ........................................................................................................................................... 11 6.4 Work Environment ................................................................................................................................... 11 6.5 Organizational Knowledge ...................................................................................................................... 11 7.0 Operation ..................................................................................................................................................... 11 7.1 Operational Planning and Control ........................................................................................................... 12 7.2 Customer-Related Activities .................................................................................................................... 12 7.2.1 Capture of Customer Requirements ............................................................................................... 12 7.2.2 Review of Customer Requirements ................................................................................................ 12 7.2.3 Customer Communication ............................................................................................................... 12 7.3 Design and Development ........................................................................................................................ 13 7.4 Purchasing .............................................................................................................................................. 13 7.5 Provision of [Production of adhesive tape] .............................................................................................. 13 7.5.1 Control of Provision of [Production of adhesive tape] ..................................................................... 13 7.5.2 Identification and Traceability .......................................................................................................... 14 7.5.3 Property Belonging to Third Parties ................................................................................................ 14 7.5.4 Preservation .................................................................................................................................... 14 7.5.5 Post-Delivery Activities .................................................................................................................... 14 7.5.6 Process Change Control ................................................................................................................. 15 7.5.7 Measurement and Release of [Production of adhesive tape] ......................................................... 15 7.5.8 Control of Nonconforming Outputs .. (15)

酒店手册(含英文翻译)

酒店手册含英文翻译 前台服务 接待:(内线电话:2100、2101) 总台接待处24小时为阁下服务,为宾客办理住宿登记,提供相关信息查询。 订房:(内线电话:2108、2118、2035) 营销中心为客人提供客房预订服务。您若有订房需要,请与营销中心联系。 结帐:(内线电话:2102) 总台结帐处24小时为您提供交付押金、退房、结帐及帐务查询服务。住客可以用现金或酒店接受的信用卡支付您的房、餐、洗衣、 旅游咨询:(内线电话2035、2114) 为您提供旅游咨询,代办旅游业务。 外币兑换:(内线电话:2102) 总台收银处提供世界通用的主要货币兑换人民币服务。 贵重物品寄存处:(内线电话:2100、2101) 总台接待处免费为您提供贵重物品寄存服务。 行李处:(内线电话:2008) 住客需要行李搬运,请与大堂行李处联系,大堂设有免费行李寄存处。 失物招领:(内线电话:2106) 如果您发现物品遗失或招领失物,请与大堂副理联系。 商场:(内线电话:2090) 为您提供各色食品、茶叶、饮品、精美工艺品、旅游纪念品、日用百货,任您选购。

商务中心:(内线电话:2114、2117) 为您提供打字、复印、传真、旅游办理、订票、邮寄、出租电脑等服务,服务时间:7:30—21:00,其余时间可与前台联系. 客房服务 小酒吧:(内线电话:2121) 房内小酒吧酒水、小食品价格详见价格表,使用时签单认可。请阁下注意:酒水饮料一经开启,无论饮用与否,其费用即计入您的帐单。若需添加,请通知客房中心。 洗衣服务:(内线电话:2121) 如您需洗衣或熨烫衣服,请将衣服准备好,装入洗衣袋内,填好洗衣单,服务员于每日上午10时前收集,当天送回。酒店亦可办理5小时加快服务,最后收取时间为15点。阁下务必将衣服中物品取出,酒店不对衣袋内物品因洗涤导致的损失负责。 宽网服务:(内线电话:2121) 阁下房间内配备国际互联网“Internet”插口,提供免费上网服务。上网操作,请参照上网须知。 客房用品:(内线电话:2121) 客房内为阁下配备了多项客房用品,如您不慎损坏或遗失,敬请赔偿。如您想购买纪念,请与房务中心联系,其费用将记入您的账单。 请勿打扰:(内线电话:9) 当您需要清静时,可将“请勿打扰”牌挂在房门外把手上,并通知总机不要将电话转到您的房间。 钥匙: 酒店使用先进的IC卡门锁,请阁下留意,当超过您预住时

ISO13485:2016质量手册英文版(修改公司名及程序名就可直接套用)

Table of Contents 1. Purpose & Scope (2) 2. Applicable Standards (2) 3. Business Profile (2) 4. Authority & Responsibility (2) 5. Terms & Definitions (2) 6. Policy & Objectives (3) 7. Application (4) 8. Quality Management System (4) 9. Management Responsibility (6) 10. Resource Management (8) 11. Product Realization (8) 12. Purchasing (11) 13. Production Control / Product Identification & Traceability (12) 14. Control of Inspection, Measuring, and Test Equipment (13) 15. Measurement, Analysis, Improvement (14)

1. Purpose & Scope This manual describes the Quality Management System (QMS) established by and for Dongguan XXX Appliances Limited. The principles and policies on which this manual is based; along with operating procedures, work instruc-tions, and other supporting documents; govern all processes that affect quality throughout the organiza-tion. 2. Applicable Standards 2.1 The QMS is structured and intended to be in compliance with the following standards. ISO 13485:2016 Medical Devices Quality Management Systems Requirements for Regulatory Purposes 21 CFR Part 820 Quality System Regulation (Exclusions and Exceptions noted below.) 2.2 Normative References ISO 9000:2015 Quality Management Systems · Fundamentals and Vocabulary ISO 13485:2016 Medical devices · Quality Management Systems · Guidance on the Application of ISO 13485:2016 3. Business Profile 3.1 Mission Statement To deliver zero defects to our internal and external suppliers and customers. 3.2 XXX, with one facility located at xxx, Dongguan City, Guangdong Province, China. 3.3 The organizational structure is described by Dongguan XXX Appliances Limited Organization Chart. 4. Authority & Responsibility 4.1 This manual is issued under the authority of the President. 4.2 It is the responsibility of the Director of Quality, who is the designated Management Representative, to ensure that the principles of this manual, the Quality Policy, quality objectives, customer requirements, applicable regulatory requirements, and quality management system requirements are promoted, com-municated to and understood by all XXX employees. 5. Terms & Definitions 5.1 Corrective Action A process improvement methodology aimed at identifying and eliminating the causes of known non-conformities to prevent their recurrence. A problem solving process.

酒店手册英文翻译

前台服务 接待:(内线电话:2100、2101) 总台接待处24小时为阁下服务,为宾客办理住宿登记,提供相关信息查询。 订房:(内线电话:2108、2118、2035) 营销中心为客人提供客房预订服务。您若有订房需要,请与营销中心联系。 结帐:(内线电话:2102) 总台结帐处24小时为您提供交付押金、退房、结帐及帐务查询服务。住客可以用现金或酒店接受的信用卡支付您的房、餐、洗衣、 旅游咨询:(内线电话2035、2114) 为您提供旅游咨询,代办旅游业务。 外币兑换:(内线电话:2102) 总台收银处提供世界通用的主要货币兑换人民币服务。 贵重物品寄存处:(内线电话:2100、2101) 总台接待处免费为您提供贵重物品寄存服务。 行李处:(内线电话:2008) 住客需要行李搬运,请与大堂行李处联系,大堂设有免费行李寄存处。 失物招领:(内线电话:2106) 如果您发现物品遗失或招领失物,请与大堂副理联系。 商场:(内线电话:2090) 为您提供各色食品、茶叶、饮品、精美工艺品、旅游纪念品、日用百货,任您选购。 商务中心:(内线电话:2114、2117) 为您提供打字、复印、传真、旅游办理、订票、邮寄、出租电脑

等服务,服务时间:7:30—21:00,其余时间可与前台联系. 客房服务 小酒吧:(内线电话:2121) 房内小酒吧酒水、小食品价格详见价格表,使用时签单认可。请阁下注意:酒水饮料一经开启,无论饮用与否,其费用即计入您的帐单。若需添加,请通知客房中心。 洗衣服务:(内线电话:2121) 如您需洗衣或熨烫衣服,请将衣服准备好,装入洗衣袋内,填好洗衣单,服务员于每日上午10时前收集,当天送回。酒店亦可办理5小时加快服务,最后收取时间为15点。阁下务必将衣服中物品取出,酒店不对衣袋内物品因洗涤导致的损失负责。 宽网服务:(内线电话:2121) 阁下房间内配备国际互联网“Internet”插口,提供免费上网服务。上网操作,请参照上网须知。 客房用品:(内线电话:2121) 客房内为阁下配备了多项客房用品,如您不慎损坏或遗失,敬请赔偿。如您想购买纪念,请与房务中心联系,其费用将记入您的账单。 请勿打扰:(内线电话:9) 当您需要清静时,可将“请勿打扰”牌挂在房门外把手上,并通知总机不要将电话转到您的房间。 钥匙: 酒店使用先进的IC卡门锁,请阁下留意,当超过您预住时间,IC将不能开启。请妥善保存您的IC卡钥匙,并避免与含磁性物品一起放置。

ISO9001质量手册英文版(ISO9001QualityManual)

ISO 9001:2000 QUALITY MANUAL WOLSTENHOLME INTERNATIONAL LIMITED CONTENTS 1.0 Scope of the Quality Management System at Wolstenholme International Limited 1.1 Statement of Quality Policy 2.0 Quality Management System Documented Procedures 2.1 Document Control 2.2 Control of Quality Records 2.3 Internal Quality Audits 2.4 Control of Nonconforming Product 2.5 Corrective Action 2.6 Preventative Action 3.0 Quality Management System Processes and Interrelations 3.1 Organisation Charts 3.2 Responsibilities 3.3 Interrelation of Processes 3.4 Processes 1.0 Scope of the Quality Management System at Wolstenholme International Limited

Wolstenholme International Limited is a Company with a long-standing successful history of supplying metal powders, pastes, pellets, varnish, offset ink, flexography ink and other related products for use in a large range of applications, on a worldwide basis. The scope of the Quality Management System encompasses all activities on the Darwen Site. The Metallic Powders Operation at Darwen is responsible for the manufacture and supply of metal powders and pigments mainly in aluminium, copper and brass (bronze) based alloys, for use in printing, inks, plastics and other industrial and engineering applications. The Ink Operation at Darwen is responsible for the manufacture of a wide range and type of printing ink, 'one-pack' gold ink, varnish and related printing products. All production processes at Darwen are validated before leaving the site and as such sub-clause 7.5.2 is excluded. The overall operation at Darwen is controlled by the Ink & Print business unit and the Industrial business unit. Technical Service and Research and Development are vital to the future development of the Company, together with understanding and developing new products and applications for our customers. The manufacturing, technical and administration functions of the Company are based in Darwen, Lancashire, England and employ some 210 staff at that location. Through the application of Quality Management Systems and Company wide training programmes, Wolstenholme International Ltd. is committed to ensuring continuous improvements to both its processes and product technology.

- ISO9001:2015质量手册-英文版

- 英文版质量手册

- ISO13485:2016质量手册英文版模板

- 质量手册翻译中英文对照

- ISO14001质量手册英文版模板(2008版)

- 质量手册英文版

- 质量手册翻译中英文对照

- 最新ISO9001:2015+3C质量手册英文版

- ISO 9001质量手册英文版(ISO 9001 Quality Manual)

- ISO9001:2015质量手册英文版

- 质量手册翻译中英文对照

- 质量手册英文版

- ISO9001:2015质量手册英文版(按标准条款)

- 质量手册翻译中英文术语表

- 质量手册翻译中英文对照

- 质量手册翻译中英文术语表24p

- IATF16949:2016质量手册英文版模板

- ISO9001质量手册英文版

- 完整英文版质量手册e

- ISO15195:2018质量手册英文版模板