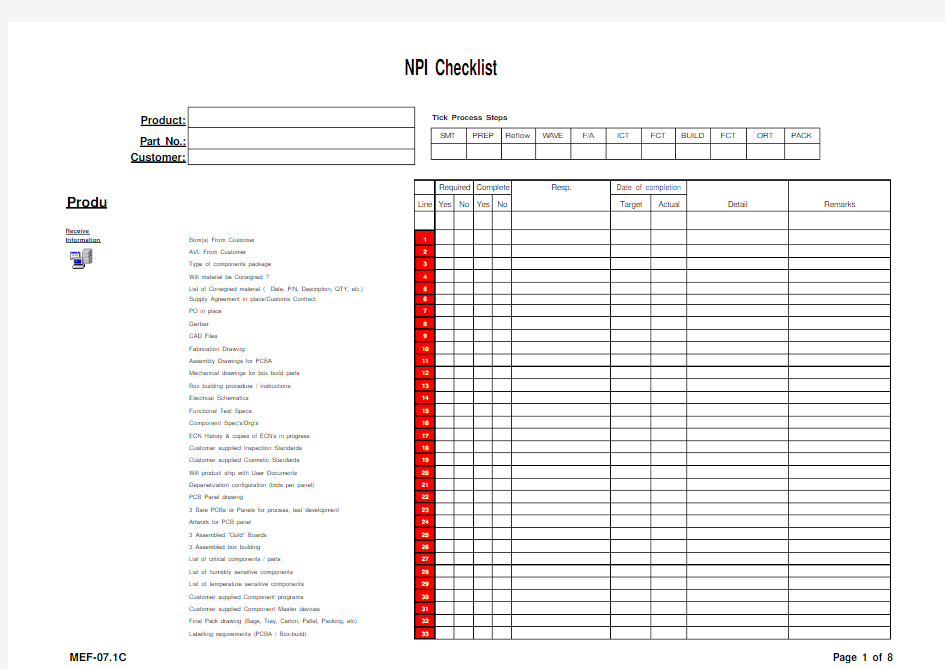

NPI Checklist

Product:Part No.:Customer:Required Complete Resp.Produ

Line Yes No Yes No Target Actual Detail Remarks Receive

Information

Bom(s) From Customer 1AVL From Customer 2Type of components package 3Will material be Consigned ?4List of Consigned material ( Date, P/N, Description, QTY, etc.)5Supply Agreement in place/Customs Contract 6PO in place 7Gerber 8CAD Files 9Fabrication Drawing 10Assembly Drawings for PCBA 11Mechanical drawings for box build parts 12Box building procedure / instructions 13Electrical Schematics 14Functional Test Specs.15Component Spec's/Drg's 16ECN History & copies of ECN's in progress 17Customer supplied Inspection Standards 18Customer supplied Cosmetic Standards 19Will product ship with User Documents 20Depanelization configuration (brds per panel)21PCB Panel drawing 223 Bare PCBs or Panels for process, test development 23Artwork for PCB panel 243 Assembled "Gold" Boards 253 Assembled box building 26List of critical components / parts 27List of humidity sensitive components 28List of temperature sensitive components 29Customer supplied Component programs 30Customer supplied Component Master devices 31Final Pack drawing (Bags, Tray, Carton, Pallet, Packing, etc)32Labelling requirements (PCBA / Box-build)33Date of completion Tick Process Steps SMT PREP Reflow WAVE F/A ICT FCT BUILD FCT ORT PACK

Method of Shipment34

Proto build required?35

Will Customer be on-site to witness build36

Product handling requirements, if any.37

Box build process engineering requirements38

Box build MPIs39

Box build test engineering requirements40

Special rework requirements, if any.41

NPI Milestone / Gantt Chart ( Proto / Pilot / Engineering Build)42 Quote Review:Material43

Labor44

Test45

NRE Cost46

Quotation for Rework47

Submit Prototype Quote48 Bom(s) on

System Item Masters on system49

All component desc. checked and complete50

Material format (tape/reel)51

ECN Level52

Product Structure loaded and verified using Cust,. BOM53

AVL loaded and verified54

Internal BOM Verification55

Release BOM on System56 Quality Quality Standards, Customer or IPC-A-610C57

Prepare Process FMEA58

Type of sampling plan defined59

Incoming receiving inspection files updated60

Workmanship Compliance61

First Article Inspection required on New Comp.s62

Any Special ESD Requirements / Relayout63

Quality Inspection Instructions released and verified64

Certificate of Conformance(s) required?65

Process audit before customer audit66

Purchasing Lead time loaded and verified67

Local Supplier Approval?68

Material Std Cost loaded69

Are all orders placed and confirmed70

Load Order on System71 Materials

Planning Production line scheduled72

Material status report73

The Date for Receive Material at Plant74

Define build quantity75

Inventory status of consigned material76

Provide Customer copy of Consigned inventory77 Kit Issues Clear-to- build report for NPI78 Plan Date SMT179

Plan Date SMT280

Plan Date HI & Wave81

Plan Date ICT82

Plan Date Functional83

Plan Date Load kanban material84

Plan Date Box Build85 Equipment &

Programms

Master list of Customer consigned equipment86

Calibration record for all consigned equipment87 Prep SMT Program88

Forming Tools89

Special equipment90

Special Training91 Screen Print Vacuum/Support Block92

Stencil in house and verified93

Solder Paste Type94

Machine set-up and process95 Glue Cure profile complete and documented96

SMT Assy Feeder & Nozzles requirements meet the need97

Special nozzle & feeder requirements, if any.98

Produ

Program complete

Placement using double sided tape

Verifiy component placement on board Reflow Profiles Profile complete and documented

Customer supplied specs.

AOI AOI Program

Solder Wave Profile complete and documented

Wave Carriers/Pallets

Flux type

Cleaning Process Water, or any special requirements

No-Clean

Box Build Inspection Jig/Fixture/Template

Operation Tools & Fixture

Depanelization MPIs

Component handling

Raised components (tooling required?)

Box build instructions

Quality Boletin for changes

Labels

packaging -MPIs

Box build Toolings / Equipment

Consumables (labels,Ribbon,box,etc.,)

Line Setup (conveyors & workbenches)

Setup Rework Stations ( Touch up )

Line Set Up( Equipments, etc.)

Tool setup (screwdrivers, fixtures,etc)

Line Configuration Layout

Kanban List & Cards

Line Balance(Time study)

Material Flow on Line

Supplies Table

Electromechanical Supplies

Production Documents Flow chart

NPI Checklist

Flow Chart Review

WI for The Machine

Indirect Material List

Packing Specification

Test

ICT ICT Platform defined152

No. of Nodes required153

Fixture in house154

Program debug155

Test program Validated156

ICT test procedure released & verified157

Troubleshoot training158

List of components which can not be tested159 EEPROM / PAL Program160

Fixture161

Tray162 Functional Test equipment163

Fixtures164

Program debug165

Test Program Validated166

Functional testing procedure released & verified167

New Kernel168

Manufacturing part number and Name of the New Flash Part Included Cheapest part.169

Algorithm for all Flash New part ( all Configurations ) if necesary170

New Kernel Tested171

New EEPROM ( X666529-002)172

New PIC SMC173

New PIC Tested174

Test Package TBD175

Test suite evaluated176 ORT Fixture177

ORT Capacity178 Industrial

Engineer Define Layout179

Supplies Table180

Quotation for Rework181

Rework area balance182

SMT Line Balance183

Packaging Area Balance184

Cycle time for new line186 Production Line available187

Line capacity188

Line layout189

Line setup190

Line Balance191

Generate Kan-Ban list/cards192

Head Count193

Operators trained and certified194

Line Audit before QA audit195 IT/Data

Collection Prepare IT System Program196

IT System Setup In Line197

Part ID Created and Loaded198

Component genealogy Collection199

Validate Label samples with new Part ID200

Define how will work Datasweep for all Configurations201

Equipment installation202

Test Label generation203

validation of all box labels204

MPI's for Data Sweep205

Screen printed and validated206

Test Application before run207 Rework ECN Level208

Re-Test Level209

BGA Rework Tools210

BGA Nozzle211

BGA Rework Profile212

Box Build Debug213

Rework station available214

Special Marking/ Training215 Packaging &

Labels Shipping Box216

Local Supplier Packaging to be approved by Customer ?217

NPI Checklist

Label Programing219

New Labelling,Data Collection Software/Specification Reqd.?220

New Printers, Barcode Scanners etc Required ?221

Serial numbers222

Anti-Static Bags223

NPI Review Inventory Customer consigned material & return224

Review labor times/ Process flow vs. Quote225

Notify Finance of Production price / MOQ226

Ready for Production release ?227

NPI Review

Report Review Pilot build w.r.t. Material Format228

DFM, Manuf. Instructions, etc.229

Issue Report to customer230

Sign off231

Team

Signat

ure Date Program Manager

NPI Leader

Manufacturing Engineer

Test Engineer

Facility Engineer

Planning

Purchasing

Prod. Supervisor

Quality Engineer

DCC