分子量的测定

Colloids and Surfaces B:Biointerfaces

57 (2007) 226–236

Surface modi?cation with well-de?ned biocompatible

triblock copolymers

Improvement of biointerfacial phenomena on a

poly(dimethylsiloxane)surface

Yasuhiko Iwasaki a,?,Mika Takamiya a,c,Ryoko Iwata a,Shin-ichi Yusa d,Kazunari Akiyoshi a,b

a Institute of Biomaterials and Bioengineering,Tokyo Medical and Dental University,2-3-10Kanda-surugadai,Chiyoda-ku,Tokyo101-0062,Japan

b Center of Excellence Program for Frontier Research on Molecular Destruction and Reconstruction of Tooth and Bone,

Tokyo Medical and Dental University,2-3-10Kanda-surugadai,Chiyoda-ku,Tokyo101-0062,Japan

c Department of Chemistry,Faculty of Science,Toho University,2-2-1Miyama,Funabashi-shi,Chiba274-8510,Japan

d Department of Materials Scienc

e and Chemistry,Graduate School o

f Engineering,University of Hyogo,2167Shosha,

Himeji-shi,Hyogo671-2280,Japan

Received12November2006;received in revised form8January2007;accepted3February2007

Available online 11 February 2007

Abstract

To improve interfacial phenomena of poly(dimethylsiloxane)(PDMS)as biomaterials,well-de?ned triblock copolymers were prepared as coating materials by reversible addition-fragmentation chain transfer(RAFT)controlled polymerization.Hydroxy-terminated poly(vinylmethylsiloxane-co-dimethylsiloxane)(HO–PV l D m MS–OH)was synthesized by ring-opening polymerization.The copolymerization ratio of vinylmethylsiloxane to dimethylsiloxane was1/9.The molecular weight of HO–PV l D m MS–OH ranged from(1.43to4.44)×104,and their molecular weight dis-tribution(M w/M n)as determined by size-exclusion chromatography equipped with multiangle laser light scattering(SEC-MALS)was1.16. 4-Cyanopentanoic acid dithiobenzoate was reacted with HO–PV l D m MS–OH to obtain macromolecular chain transfer agents(macro-CTA). 2-Methacryloyloxyethyl phosphorylcholine(MPC)was polymerized with macro-CTAs.The gel-permeation chromatography(GPC)chart of synthesized polymers was a single peak and M w/M n was relatively narrow(1.3–1.6).Then the poly(MPC)(PMPC)–PV l D m MS–PMPC triblock copolymers were synthesized.The molecular weight of PMPC in a triblock copolymer was easily controllable by changing the polymerization time or the composition of the macro-CTA to a monomer in the feed.The synthesized block copolymers were slightly soluble in water and extremely soluble in ethanol and2-propanol.

Surface modi?cation was performed via hydrosilylation.The block copolymer was coated on the PDMS?lm whose surface was pretreated with poly(hydromethylsiloxane).The surface wettability and lubrication of the PDMS?lm were effectively improved by immobilization with the block copolymers.In addition,the number of adherent platelets from human platelet-rich plasma(PRP)was dramatically reduced by surface modi?cation.Particularly,the triblock copolymer having a high composition ratio of MPC units to silicone units was effective in improving the surface properties of PDMS.

By selective decomposition of the Si–H bond at the surface of the PDMS substrate by irradiation with UV light,the coating region of the triblock copolymer was easily controlled,resulting in the fabrication of micropatterns.On the surface,albumin adsorption was well manipulated.

? 2007 Elsevier B.V. All rights reserved.

Keywords:Phosphorylcholine polymer;PDMS;RAFT polymerization;Block copolymer;Surface modi?cation;Non-fouling;Lubrication

?Corresponding author.Tel.:+81352808022;fax:+81352808027. E-mail address:https://www.wendangku.net/doc/5513282958.html,@tmd.ac.jp(Y.Iwasaki).1.Introduction

Poly(dimethylsiloxane)(PDMS)is one of the most valuable polymers for use in biomedical devices such as catheters,tra-cheoesophageal voice prostheses,?nger joints,percutaneous devices,dentures,etc.[1].One of the more recent trends in PDMS applications is micro?uidic devices for biosensors or

0927-7765/$–see front matter? 2007 Elsevier B.V. All rights reserved. doi:10.1016/j.colsurfb.2007.02.007

Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236227

biochips[2–5].PDMS has?exibility,high gas permeability,pro-cessability,?exible surface chemistry,and optical transparency. However,the interface of the PDMS surface with the biologi-cal environment is inadequate,and non-speci?c biofouling,i.e., protein adsorption and cell adhesion frequently occurs on the surface[6–9].Biofouling induces contamination,in?ammation, infection,and the reduction of material function.Highly friction of PDMS surface is also unfavorable nature for medical applica-tions.These disadvantages of PDMS are due to hydrophobicity of the surface,necessitating surface modi?cation.The forma-tion of a hydrophilic surface on PDMS by using oxidization [10,11]and hydrophilic polymers[12–14]is proposed as a method of solving interfacial problems.Poly(ethylene glycol) (PEG)is one of the principal polymer candidates for reducing non-speci?c fouling at the biointerface[15].For PDMS,cova-lent bonding onto PDMS surfaces of PEG-functionalized silanes [16–18]or amine-functionalized silanes to further react with PEG-moieties[19,20]has generally been employed.PEGylation is very effective in reducing biofouling.However,cell adhesion was observed on surfaces after long-term exposure in a culture medium[21].

To obtain other types of reliable non-fouling surfaces,we have been studying2-methacryloyloxyethyl phosphorylcholine (MPC)polymers synthesized as biomimetics in biomembrane structures[22–24].There have been some reports describing the surface modi?cation of PDMS with MPC.Plasma-induced graft polymerization was applied as a primary process[25,26]. However,this modi?cation has limitations in increasing the surface composition of MPC units because the phosphorus con-centration remained low compared with the theoretical amount calculated from the chemical structure of MPC.Goda et al. recently reported the photo-induced grafting of MPC on a PDMS surface[14].They succeeded in improving the composition of the MPC units on the PDMS surface compared with plasma polymerization.Moreover,the surface friction of PDMS sur-face effectively reduced by the surface modi?cation.Although surface modi?cation with MPC polymers via the grafting pro-cess is valuable for achieving a non-fouling surface on PDMS, their use precludes accurate control of the polymer structure and speci?c equipment is required.

Surface-coating processes are more applicable as methods of surface modi?cation.Generally,organic solvent is used for the surface modi?cation of PDMS,and the coating of hydrophilic polymer on PDMS is dif?cult because the surface is hydrophobic and has a low surface energy.The surface modi?cation of PDMS using polar solvent is still limited[27].A precise molecular design of an MPC polymer having the desired solubility and anchors that have an af?nity to the PDMS surface is needed for reliable surface modi?cation.

To produce well-de?ned polymers,controlled“living”radi-cal polymerization has been explored[28].Atom transfer radical polymerization(ATRP)and reversible addition-fragmentation chain transfer(RAFT)polymerization are very useful for achiev-ing this process because they can be applied to a wide variety of monomers[29–35].We have prepared poly(MPC)(PMPC) brush on a silicon wafer via ATRP and clari?ed that plasma protein adsorption and cell adhesion were effectively

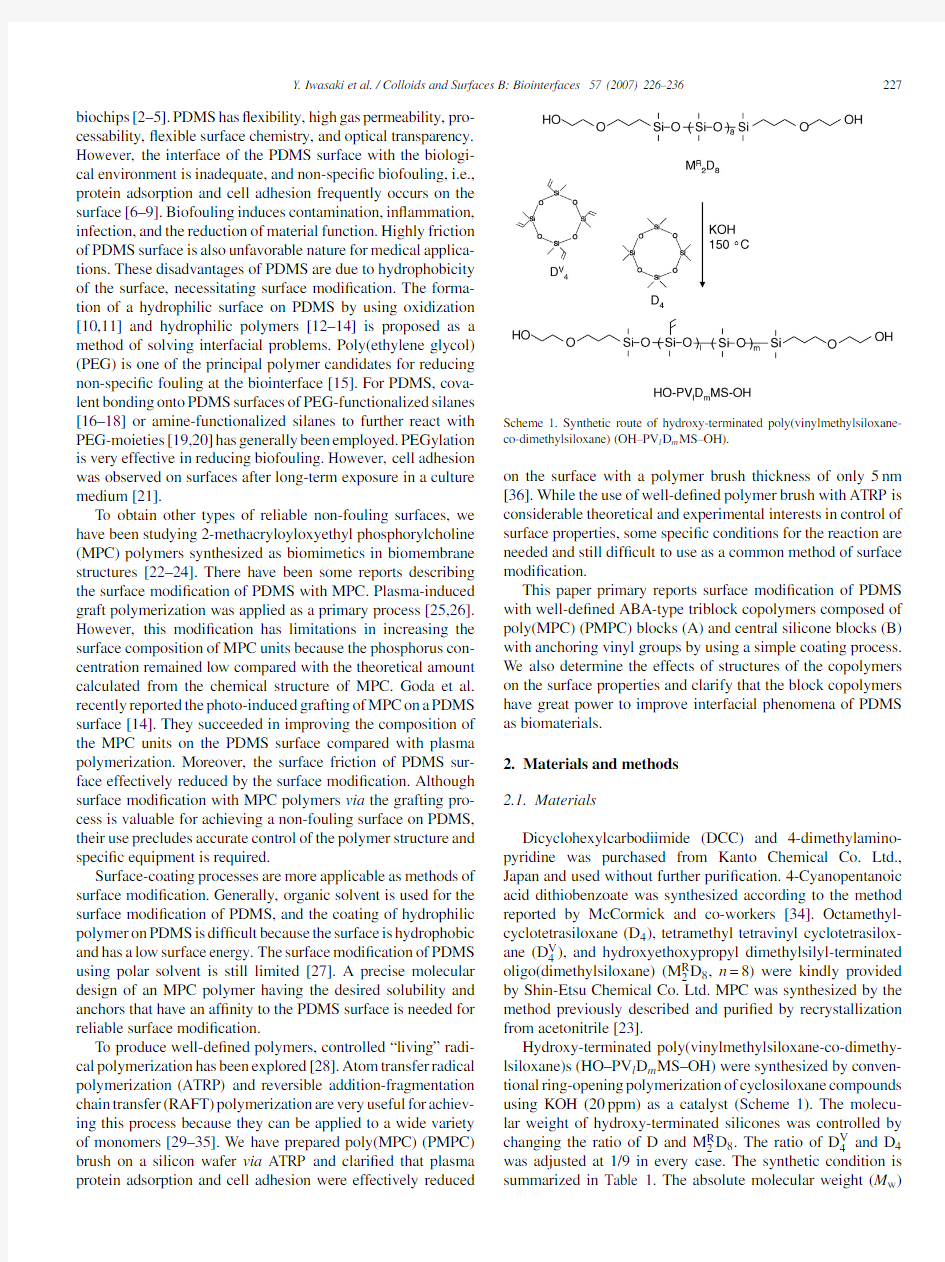

reduced Scheme1.Synthetic route of hydroxy-terminated poly(vinylmethylsiloxane-co-dimethylsiloxane)(OH–PV l D m MS–OH).

on the surface with a polymer brush thickness of only5nm [36].While the use of well-de?ned polymer brush with ATRP is considerable theoretical and experimental interests in control of surface properties,some speci?c conditions for the reaction are needed and still dif?cult to use as a common method of surface modi?cation.

This paper primary reports surface modi?cation of PDMS with well-de?ned ABA-type triblock copolymers composed of poly(MPC)(PMPC)blocks(A)and central silicone blocks(B) with anchoring vinyl groups by using a simple coating process. We also determine the effects of structures of the copolymers on the surface properties and clarify that the block copolymers have great power to improve interfacial phenomena of PDMS as biomaterials.

2.Materials and methods

2.1.Materials

Dicyclohexylcarbodiimide(DCC)and4-dimethylamino-pyridine was purchased from Kanto Chemical Co.Ltd., Japan and used without further puri?cation.4-Cyanopentanoic acid dithiobenzoate was synthesized according to the method reported by McCormick and co-workers[34].Octamethyl-cyclotetrasiloxane(D4),tetramethyl tetravinyl cyclotetrasilox-ane(D V4),and hydroxyethoxypropyl dimethylsilyl-terminated oligo(dimethylsiloxane)(M R2D8,n=8)were kindly provided by Shin-Etsu Chemical Co.Ltd.MPC was synthesized by the method previously described and puri?ed by recrystallization from acetonitrile[23].

Hydroxy-terminated poly(vinylmethylsiloxane-co-dimethy-lsiloxane)s(HO–PV l D m MS–OH)were synthesized by conven-tional ring-opening polymerization of cyclosiloxane compounds using KOH(20ppm)as a catalyst(Scheme1).The molecu-lar weight of hydroxy-terminated silicones was controlled by changing the ratio of D and M R2D8.The ratio of D V4and D4 was adjusted at1/9in every case.The synthetic condition is summarized in Table1.The absolute molecular weight(M w)

228Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

Table1

Synthetic results of hydroxy-terminated poly(dimethylsiloxane-co-vinylmethylsiloxane)(OH–PV l D m MS–OH)

Code M R

2

D8/(Me2SiO)4/(MeViSiO)4(mol)Me2SiO/MeViSiO(molar fraction)M w(×104)M w/M n

In feed In copolymer a

OH–PV17D173MS–OH1/37/50.89/0.110.91/0.09 1.43b 1.16b OH–PV32D324MS–OH1/82/100.89/0.110.91/0.09 2.68b 1.16b OH–PV53D537MS–OH1/172/200.90/0.100.91/0.09 4.44c–

a Determined by1H NMR.

b Absolute molecular weight:determined by MALLS.

c Calculate

d from apparent molecular weight.

of the HO–PV l D m MS–OH was determined by size-exclusion chromatography equipped with multiangle laser light scatter-ing(SEC-MALS)analysis with a Shodex KF-806L column and a Wyatt Dawn HELEOS detector.The apparent molecular weights of the HO–PV l D m MS–OH were also measured using gel-permeation chromatography(GPC)through a Shodex KF-803column using a calibration curve based on linear polystyrene standards.THF was used as the GPC solvent.

To obtain a macromolecular chain transfer agent(macro-CTA),DCC(4.0molar to HO–PV l D m MS–OH)in CH2Cl2 (100mL)was added dropwise to a CH2Cl2(100mL)solu-tion of4-cyanopentanoic acid dithiobenzoate(2.4molar to HO–PV l D m MS–OH)and HO–PV l D m MS–OH(30g)and stirred for20h at40?C(Scheme2).The solution was then?l-tered to remove any insoluble substances.After evaporation of CH2Cl2,the reaction mixture was washed with methanol until the methanol was colorless,diluted with chloroform,washed three times with brine,dried over MgSO4,and concentrated.A viscous liquid was obtained.The chemical structure of macro-CTA was con?rmed by1H NMR(?-500,JEOL,Tokyo,Japan) and FT-IR spectroscopy(FT-500,Jasco,Tokyo,Japan).1H NMR (500MHz,CDCl3):δ=macro-CTA:?0.2to0.2(m;Si–CH3), 1.9(s;CN–C–C H3),2.35–2.75(m;–C–C H2–C H2–COOH), 5.6–5.8(m;–C H CH2),5.8–6.0(m;–CH C H2),7.3–7.9(m; Ph).

2.2.Synthesis of block copolymers

Because the radical for polymerization was sensitive to air,all reactions were performed in an argon gas atmo-sphere.The synthetic condition of the block copolymers is summarized in Table2.Typically,?,? -azobisisobutyronitrile (AIBN,0.025mmol)was introduced through a polymerization tube.MPC(4.43g,15.0mmol)and macro-CTA(PD324V32MS, 0.05mmol)were desorbed in a toluene/ethanol(1/1)mixture, and the volume of the solution was adjusted to30mL.Then, argon gas was passed through the solution for30min to elimi-nate oxygen.The solution was heated at70?C and stored with gentle shaking for given periods.After polymerization,the block copolymer was precipitated into THF,then dissolved in ethanol, and again precipitated into THF.The precipitation was dried in vacuo.The synthetic route of the PMPC–PV l D m MS–PMPC triblock copolymers is shown in Scheme3.

The number-and weight-averaged molecular weights of the block copolymers were measured with a Tosoh GPC system with a refractive index detector and size-exclusion columns,Shodex, SB-804HQ and SB-806M HQ with a poly(ethylene glycol) (PEG,Tosoh standard sample)standard in20vol.%methanol containing10mM LiBr.The molar fraction of the MPC unit of block copolymer was also determined by phosphorus analysis.

2.3.Preparation of silicone substrate and surface functionalization

Silpot184PDMS prepolymer was mixed thoroughly with its cross-linking catalyst(10:1,w/w)and poured into a Petri dish. After the bubbles were removed from the prepolymer under reduced pressure,the?lms were cured at100?C for3h.The cured?lm was removed from the plate and cut into1.4cm diam-eter disks.The?lm disks were washed thoroughly with

hexane Scheme2.Synthetic route of macro chain transfer agent(macro-CTA).

Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

229

Table 2

Synthetic results of PMPC–PV l D m MS–PMPC triblock copolymers Code Copolymers

MPC/macro-CTA/AIBN (mol)in feed a PMPC PD(one side)in copolymer b M w (×104)c M w /M n PMPC/silicone d 26–173PMPC 26–PV 17D 173MS–PMPC 26 1.5×10?2/1×10?4/5×10?526.0 2.32 1.270.2735–173PMPC 35–PV 17D 173MS–PMPC 35 1.5×10?2/5×10?5/2.5×10?534.7 3.53 1.310.3753–173PMPC 53–PV 17D 173MS–PMPC 53 1.5×10?2/2.5×10?5/1.25×10?552.7 6.85 1.410.5554–324PMPC 54–PV 32D 324MS–PMPC 54 1.5×10?2/1×10?4/5×10?554.2 3.93 1.280.3066–324PMPC 66–PV 32D 324MS–PMPC 66 1.5×10?2/5×10?5/2.5×10?566.3 6.23 1.410.37119–324PMPC 119–PV 32D 324MS–PMPC 119 1.5×10?2/2.5×10?5/1.25×10?5118.69.85 1.630.6675–325PMPC 75–PV 53D 537MS–PMPC 75 1.5×10?2/1×10?4/5×10?575.38.47 1.470.2699–537PMPC 99–PV 53D 537MS–PMPC 99 1.5×10?2/5×10?5/2.5×10?599.211.30 1.550.34153–537

PMPC 153–PV 53D 537MS–PMPC 153

1.5×10?2/

2.5×10?5/1.25×10?5

152.2

16.64

1.63

0.52

a [MPC]=0.5mol/L;[CTA]/[AIBN]=2;polymerization temperature 70?C;solvent:ethanol/toluene =1/1(v/v).

b Determined by phosphorus analysis,PD:polymerization degree.

c Determine

d by GPC,eluent:MeOH/H 2O =20/80with 10mM LiBr.d

n ×2/(l +m ),PMPC n –PV l D m MS–PMPC n

.

Scheme 3.Synthetic route of PMPC–PV l D m MS–PMPC triblock copolymer.

and acetone and dried under in vacuo for 1day at room tem-perature.The surface functionalization of the PDMS ?lms was processed as previously described [37].Brie?y,the silicone ?lms were incubated in a solution of poly(hydromethylsiloxane)(KF-99-P ?):2-propanol (3:5,v/v)containing tri?ic acid as a catalyst (0.02mL)with stirring for 15min at room temperature.The sil-icone ?lms were then removed from the solution and washed thoroughly with 2-propanol and hexane,then dried in vacuo for 1day at room temperature.The presence of surface Si–H groups (absorption peak at 2167cm ?1)was con?rmed by ATR-FT-IR.

2.4.Surface modi?cation of silicone ?lms with PMPC–PV l D m MS–PMPC triblock copolymer

A solution (5g)of 1wt%PMPC–PV l D m MS–PMPC triblock copolymers desorbed in ethanol was prepared and Pt-catalyst (platinum–divinyltetramethyldisiloxane complex)(two drops)was added to the polymer solution.The solution was dropped onto a Si–H functionalized silicone ?lm and spin-coated at 4000rpm for 10s.The ?lm was heated at 80?C for 2h,then rinsed by soaking in ethanol for 24h at 50?C.The ethanol was changed several times.The ?lm was then dried in vacuo .Fig.1is

a schematic representation of the surface modi?cation of PDMS with PMPC–PV l D m MS–PMPC triblock copolymers.2.5.Surface analysis

X-ray photoelectron spectroscopy (XPS)was performed on a Scienta ESCA-200spectrometer with Al K ?.Survey

scans

Fig. 1.Schematic representation of surface modi?cation of PDMS with PMPC–PV l D m MS–PMPC triblock copolymer.

230Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

spectra of C1s,O1s,N1s,and P2p were obtained.All XPS data were collected at take off angles of75?(between the specimen surface and the detector).

The dynamic contact angles for the samples were recorded as the probe?uid,water(deionized to18.2M ),using a First Ten Angstroms FT-125goniometer and Gilmont syringes.The advancing(θA)and receding(θR)contact angles were mea-sured with addition to and withdrawal from the drop,respec-tively.

The surface frictional coef?cients during startup and under steady state conditions were measured using a surface property tester(Heidon Type32,Shinto Science Co.,Tokyo,Japan).Sam-ple?lms(φ=1.4cm)were thoroughly wet with water before and during the measurements.The measurements were conducted by sliding the membrane under a100g load using a stainless steel ball(10mm in diameter).The scan speed and scale were 10mm/s.

2.6.Platelet adhesion test

Human platelet-rich plasma(PRP)was prepared from cit-rated whole blood by centrifugation.Polymer samples were placed in a24-well tissue culture plate and secured with a sil-icone rubber ring.The PBS was allowed to stand in the wells overnight to equilibrate the surface.PRP was poured into each well and stored at room temperature for60min.The polymer surfaces in contact with PRP were observed by a scanning electron microscope(S-3400NX,Hitachi High-Technologies Co.,Tokyo,Japan).The density of adherent platelets was determined by measuring lactic acid dehydrogenase(LDH) from the platelets[38].After the PRP was incubated on the polymer samples,the samples were rinsed three times with PBS.The samples were then transferred to a new24-well tissue culture plate.Triton X-100(0.5wt%,1mL)was intro-duced into each well and incubated for30min.The Triton X-100solution(250?L)was collected and the concentration of LDH from the adherent platelets was measured by the LDH-Cytotoxic Test kit(Wako Pure Chemical Industries,Ltd., Japan).

2.7.Controlled protein adsorption on surface patterned

with UV-light irradiation

UV light(λ=185nm)(GL15ZH,Sankyo Denki Co.Ltd., 15W)was irradiated on a poly(hydromethylsiloxane)-treated PDMS surface through a mesh used for transmission electron microscopy(hole45?m,bar40?m;Okenshoji Co.Ltd.,Tokyo, Japan)for3h in air.The UV-irradiated surfaces were then immobilized with the triblock copolymer(119–324)mentioned above.

The surface was exposed to0.45g/dL?uorescein isothio-cyanate(FITC)-labeled bovine albumin(Sigma Chemicals,St. Louis,MO,USA)in phosphate-buffered solution(PBS)for 30min and rinsed with PBS and water.The sample was dried in an argon stream and observed using a?uorescent microscope (IX-70,Olympus Co.,Tokyo,

Japan).

Fig.2.IR spectra of PV17D173MS and macro-CTA.

3.Results and discussion

3.1.Synthesis of triblock copolymers

Hydroxy-terminated poly(dimethylsiloxane)copolymers (HO–PV l D m MS–OH)were synthesized by ring-opening poly-merization of cyclotetrasiloxane compounds(Scheme1).The ratio of dimethylsiloxane and vinylmethylsiloxane in the copolymer could be controlled by their ratio in the feed. The molecular weight of the synthesized silicone compounds was measured by SEC-MALS.For HO–PV17D173MS–OH and HO–PV32D324MS–OH,the absolute molecular weights were(1.43and 2.68)×104,respectively.Their ratio of apparent molecular weight measured by GPC to absolute molecular weight was 1.4.The absolute molecular weight of HO–PV53D537MS–OH was calculated at4.44×104from the apparent molecular weight.The molecular weight of HO–PV53D537MS–OH increased linearly(r2=0.99)with an increase in the monomer ratio to M R2D8.

4-Cyanopentanoic acid dithiobenzoate,that is,the RAFT agent was reacted with the HO–PV l D m MS–OH by condensa-tion.Fig.2shows the FT-IR spectra of HO–PV l D m MS–OH and that reacted with the4-cyanopentanoic acid dithioben-zoate.After the reaction,absorption due to the carbonyl group at1750cm?1was observed.The absorption of the hydroxyl group at3500cm?1diminished.Quantitative determination of the condensation was performed by1H NMR.In every case, the composition of the RAFT agent was approximately2when the molecular weight of the silicone compound determined by SEC-MALS was used.

Living radical polymerization has a great deal of synthetic power in controlling the molecular architecture of polymers and is an exceptionally robust method for producing block or graft copolymers[28,39–41].The living radical polymerization of MPC recently resulted in the preparation of biocompatible block [35,42–45]and graft copolymers[46,47].

While Ma et al.?rstly synthesized a series of diblock and triblock copolymers of PMPC and oligodimethylsilox-ane via ATRP,the characterization of the block copolymers was not described in detail because of the solubility

Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

231

Fig.3.Dependence of M w on conversion in the polymerization of MPC: ( )PMPC–PV17D173MS–PMPC;( )PMPC–PV32D324MS–PMPC;( ) PMPC–PV53D537MS–PMPC.

difference of the components[42].We also tried to syn-thesize macro-initiator for ATRP.However,the decrease in the molecular weight of HO–PV l D m MS–OH was observed when HO–PV l D m MS–OH was reacted with2-bromoisobutyryl bromide.

RAFT polymerization of MPC with RAFT agent-capped sili-cone as a dithioester chain transfer agent(macro-CTA)was then performed in toluene/ethanol(1/1)at70?C.Even though macro-CTAs have vinyl groups as side chains,any gelation during polymerization was not observed.Fig.3shows the relationship between the molecular weight determined by GPC and the con-version of the MPC polymers.In every polymer system,the GPC results show a single peak and the molecular weight of the block copolymer is linear with conversion.Fig.4shows that the monomer consumption followed?rst order kinetics.The semi-logarithmic plot indicates that polymerization is?rst order with respect to MPC and implies that the polymer radical concentra-tion remains constant on the polymerization time scale.Table2 summarizes the characterization of PMPC–PV l D m MS–PMPC triblock copolymers with various chain lengths.The degree of polymerization(PD)of the MPC polymer increased with an increase in the ratio of MPC to macro-CTA.The yield of poly-merization related with polymerization kinetics and increased with an increase in the molecular weight of macro-CTA.The

molecular weight distributions were relatively larger with

the

Fig. 4.Kinetics of RAFT polymerization of MPC:( )PMPC–PV17 D173MS–PMPC;( )PMPC–PV32D324MS–PMPC;( )PMPC–PV53 D537

MS–PMPC.Fig.5.Water contact angles of native silicone?lm and that coated with block copolymers:( )advancing contact angle(θA);( )receding contact angle(θR). *represents spreading of water drop.

higher molecular weights.The ratio of MPC and silicone units was calculated from the phosphorus analysis data.When PV32D324MS was used as macro-CTA,the composition of the MPC units in a copolymer was higher than that of other macro-CTAs.

3.2.Surface modi?cation and characterization of PDMS

with triblock copolymers

All copolymers were dissolved in ethanol and coated on silicone?lms.The water contact angle data was recorded using specimens dried for several hours under reduced pressure before measurement(Fig.5).The data for the native PDMS wasθA/θR=116?/96?and did not change by treatment with poly(hydromethylsiloxane).TheθA on the surface coated with the triblock copolymers was recorded at the?rst addition of water and it gradually decreased with an increase in the compo-sition of the MPC unit in the copolymers.TheθR on the modi?ed surface was decreased dramatically to less than30?.Particularly, theθR on a surface coated with copolymers(119–324,99–537, and153–537)could not be measured because the water drop spread completely.

The elemental analyses of the polymer-coated silicone sur-faces were performed with XPS.In the case of a silicone?lm coated with the triblock copolymer(66–324),nitrogen and phos-phorus peaks were observed at402.5and134.0eV,respectively (Fig.6).These were not observed on the native silicone?lm and were attributed to the phosphorylcholine group in the MPC units.To affect the chemical reaction of surface modi?cation, the triblock copolymer was treated without a Pt catalyst or Si–H treatment.In both cases,the phosphorus and nitrogen sig-nals caused by the MPC polymers were negligible.The surface modi?cation with the triblock copolymers was then performed through hydrosilylation.The XPS phosphorus concentration of the surface-modi?ed silicone?lms is summarized in Fig.7.The increment of concentration was caused by an increase in the bulk composition of the MPC unit in the triblock copolymers. Although the block copolymer with a longer central silicone chain(153–537)has longer PMPC chains,the XPS phospho-rus concentration on the surface coated with153–537was less

232Y.Iwasaki et al./Colloids and Surfaces B:

Biointerfaces 57 (2007) 226–236

Fig.6.XPS spectra of native silicone ?lm and that coated with the triblock copolymer (66–324).

than that on the surface coated with 119–324.This result indi-cates that the central silicone block with high molecular weight reduce the density of PMPC chains on the surface.Sugiyama et al.synthesized poly(MPC-b -PDMS)by conventional radi-cal polymerization and surface modi?cation of PDMS with the block copolymer was performed [48].While the block copoly-mers improved wettability,the contact angle was still higher than that on comb-shaped polymer brush surface of PMPC [36].The silicone segments of the block copolymers in?uenced the mobil-ity of PMPC segments.On the other hand,the PMPC segments of ABA typed block copolymers synthesized in this study

were

Fig.7.XPS phosphorus concentration of silicone ?lms modi?ed with PMPC–PV l D m MS–PMPC triblock copolymers.

free.Highly wettable surfaces were obtained due to the ABA typed structure.

One of the interesting properties of MPC polymers is to pro-duce lower friction and improved boundary lubrication under wet condition [49]and this property is important for making biomedical devices such as,catheters.To clarify the effect of chemical structure of block copolymers on improving boundary lubrication,we measured surface friction of modi?ed surfaces.Fig.8shows the friction coef?cient of the silicone ?lms coated with triblock copolymers at startup (static)and in the steady (kinetic)conditions in water.The static and kinetic friction coef-?cients of non-treated silicone ?lm were coef?cient 2.0±0.4and 1.4±0.3,respectively.These coef?cients were signi?cantly reduced by triblock copolymer coatings.The surface friction was decreased with an increase in the ratio of MPC in a copolymer.Even if the 153–537has long PMPC blocks,the longer silicone block is an obstacle to improve surface lubrication.In the case of the triblock copolymer (119–324)-coated surface,the kinetic friction coef?cient was less than 0.01.The surface friction was effectively reduced by coating of optimally sequenced ABA block copolymers as well as “grafting from”typed surface mod-i?cation [14].This phenomenon is attributed to the removal of the strong hydrophobic interaction between the PDMS surfaces in water [50]and a similar state of hydrodynamic lubrication.Moro et al.investigated the effects of the graft polymeriza-tion of MPC onto polyethylene surfaces.They clari?ed that MPC grafting remarkably decreased friction and the amount of wear [51].The PMPC–PV l D m MS–PMPC triblock copolymers syn-

Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

233

Fig.8.Friction coef?cients of silicone?lms modi?ed with block copolymers:( )startup;( )steady state;(a)all data;(b)selected data for a better reading.The values in parentheses:n×2/(l+m),PMPC n–PV l D m MS–PMPC n.

thesized in this study can be chemically introduced on various surfaces through the reactivity of the vinyl group in the central silicone chain.

Fig.9shows the results of a continuous friction test on a silicone?lm and that coated with the triblock copolymer (119–324).The low friction coef?cient of a surface coated with the triblock copolymer(119–324)did not change during the determination.This result indicates that surface modi?cation with a block copolymer is stable due to chemical bonding to the substrate.The long-term stability of coating layer and the in?uence of percentage of vinyl unit will be presented in near future.

3.3.Non-fouling behavior on PDMS surface coated with PMPC–PV l D m MS–PMPC triblock copolymers

Fig.10shows SEM pictures of a polymer surface after contact with human PRP for60min.Many platelets adhered and were active on the non-treated silicone surface.In con-trast,platelet adhesion was effectively reduced on the PDMS surface coated with the triblock copolymer(119–324).The quantitative result for adherent platelets on various surfaces is summarized in Fig.11.On every PMPC–PV l D m MS–PMPC tri-block copolymer-immobilized surface,the number of adherent platelets was signi?cantly smaller than that on a non-treated silicone surface.Moreover,platelet adhesion was signi?cantly decreased on the surface coated with119–324compared to that coated with153–537,that is,the surface density of PMPC chains also in?uenced non-fouling properties.The suppression of platelet adhesion on the block copolymer-coated surfaces is due to the reduction of plasma protein adsorption.In the for-mer literatures[23,24,52],the mechanism of protein adsorption resistance on MPC polymers has been well reported and the property was observed regardless of type of protein.The reduc-tion of albumin adsorption on the surface coated with a triblock copolymer is presented in Fig.12.

Surface modi?cation with well-de?ned MPC polymers on a solid surface produced by living radical polymerization has been chie?y reported by Feng et al.[53].The effect of thickness and density of the PMPC polymer on protein adsorption is also well characterized[54].Surface samples with various graft den-sities from0.06to0.39chains/nm2and chain lengths from5to 200MPC units were prepared.They clari?ed that the surfaces with high graft densities and high PMPC chain lengths showed dramatic reductions in?brinogen adsorption.A well-de?ned surface structure bearing a free end of the polymer chain must be advantageous for obtaining the ef?ciency of MPC polymers on non-fouling phenomena.The PMPC–PV l D m MS–PMPC tri-block copolymer is suitable for fabricating this surface structure by a simple coating process.

Adsorption of FITC-labeled BSA was well controlled on a patterned polymer surface,as shown in Fig.12.In the

region Fig.9.Continuous friction test for a silicone?lm and that coated with the triblock copolymer(119–324).

234Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

Fig.10.SEM pictures of polymer surfaces after contact with PRP for60min.

Fig.11.Surface density of adherent platelets on polymer surfaces in contact with PRP for60min:(a)all data;(b)selected data for a better reading.The values in parentheses:n×2/(l+m),PMPC n–PV l D m MS–PMPC n.

Fig.12.FITC-albumin adsorption on PDMS surface coated with the triblock copolymer(119–324)with micropatterning after contact with0.45g/dL FITC-albumin in PBS for30min.

Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236235

irradiated with UV,no Si–H bond was determined by ATR-FT-IR(data not shown).Fig.6shows that surface modi?cation is performed via hydrosilylation,that is,Si–H bond is required on the substrate surface.The triblock copolymer(119–324)selec-tively reacted with the non-UV-irradiated region.The intensity of the surface?uorescence of the UV-irradiated region was sig-ni?cantly high.This indicates that a large amount of BSA was adsorbed on this region.In contrast,BSA adsorption was effec-tively reduced on the region covered with mesh.The protein adsorption behavior con?rmed that the surface modi?cation with block copolymers was performed thorough hydrosilylation.The surface modi?cation with ABA block copolymers can prepare highly de?ned micropatterns and their potential applicability to biosensor and drug screening development will be demonstrated.

4.Conclusion

For the surface modi?cation of PDMS,PMPC–PV l D m MS–PMPC triblock copolymers were synthesized via RAFT poly-merization.Polymerization of each unit was well controlled and the molecular weight distribution was relatively low.The rate of copolymerization of MPC depends on the molecular weight of the macro-CTA.The copolymers were coated on PDMS and chemically bonded via hydrosilylation.The sur-face wettability of the copolymer-immobilized surface was signi?cantly improved compared with that of native PDMS. Copolymers are very effective in reducing the coef?cient of friction of the surface.Platelet adhesion and protein adsorp-tion on the PDMS surface coated with triblock copolymers was reduced dramatically.To optimize the sequence of block copolymers is very important because the surface proper-ties coated with the block copolymers depend on both the molecular weight and density of PMPC chains,and RAFT polymerization well works to achieve this process.We also succeeded in controlling the size of the modi?cation area on a microscale and in manipulating protein adsorption on the surface.

Acknowledgments

This work was supported by the Japan Society for the Pro-motion of Science(Grant-in-Aid for Encouragement of Young Scientists(#18681018)).We gratefully acknowledge the valu-able discussions provided by Dr.Kazuhiko Ishihara of The University of Tokyo and Mr.Masayuki Ikeno of Shin-Etsu Chemical Co.Ltd.

References

[1]J.Curtis,A.Coals,in:B.D.Ratner,A.S.Hoffman,F.J.Schoen,J.E.Lemons

(Eds.),Biomaterials Science,2nd ed.,Elsevier Academic Press,San Diego, 2004(Chapter7).

[2]J.C.McDonald,D.C.Duffy,J.R.Anderson,D.T.Chiu,H.Wu,O.J.

Schueller,G.M.Whitesides,Electrophoresis21(2000)27.

[3]J.Soo Ko,H.C.Yoon,H.Yang,H.B.Pyo,K.Hyo Chung,S.Jin Kim,Y.

Tae Kim,Lab Chip3(2003)106.

[4]https://www.wendangku.net/doc/5513282958.html,mmertink,S.Schlautmann,G.A.Besselink,R.B.Schasfoort,Anal.

Chem.76(2004)3018.

[5]M.Ebara,J.M.Hoffman,A.S.Hoffman,P.S.Stayton,Lab Chip6(2006)

843.

[6]W.J.Kao,Q.H.Zhao,A.Hiltner,J.M.Anderson,J.Biomed.Mater.Res.

28(1994)73.

[7]M.C.Belanger,Y.Marois,J.Biomed.Mater.Res.58(2001)467.

[8]C.Leunisse,R.van Weissenbruch,H.J.Busscher,H.C.van der Mei,F.

Dijk,F.W.Albers,J.Biomed.Mater.Res.58(2001)556.

[9]C.Price,M.G.Waters,D.W.Williams,M.A.Lewis,D.Stickler,J.Biomed.

Mater.Res.63(2002)122.

[10]M.Morra,E.Occhiello,F.Garbassi,M.Maestri,R.Bianchi,A.Zonta,

Clin.Mater.5(1990)147.

[11]S.L.Peterson,A.McDonald,P.L.Gourley,D.Y.Sasaki,J.Biomed.Mater.

Res.72(2005)10.

[12]S.Hu,X.Ren,M.Bachman,C.E.Sims,G.P.Li,N.Allbritton,Anal.Chem.

74(2002)4117.

[13]Y.Yuan,X.Zang,F.Ai,J.Zhou,J.Shen,S.Lin,Polym.Int.53(2004)

121.

[14]T.Goda,T.Konno,M.Takai,T.Moro,K.Ishihara,Biomaterials27(2006)

5151.

[15]C.-G.Golander,J.N.Herron,K.Lim,P.Claesson,P.Stenius,J.D.Andrade,

in:J.M.Harris(Ed.),Poly(ethylene glycol)Chemistry,Plenum Press,New York,1992(Chapter15).

[16]A.Papra,N.Gadegaard,https://www.wendangku.net/doc/5513282958.html,rsen,Langmuir17(2001)

1457.

[17]A.Papra,A.Bernard,D.Juncker,https://www.wendangku.net/doc/5513282958.html,rsen,B.Michel,E.Delamarche,

Langmuir17(2001)4090.

[18]E.Delamarche,C.Donzel,F.S.Kamounah,H.Wolf,M.Geissler,R.Stutz,

P.Schmidt-Winkel,B.Michel,H.J.Mathieu,K.Schaumburg,Langmuir 19(2003)8749.

[19]C.Donzel,M.Geissler,A.Bernard,H.Wolf,B.Michel,J.Hilborn,E.

Delamarche,Adv.Mater.13(2001)1164.

[20]D.Wu,B.Zhao,Z.Dai,J.Qin,B.Lin,Lab Chip6(2006)942.

[21]X.Fan,L.Lin,P.B.Messersmith,Biomacromolecules7(2006)

2443.

[22]K.Ishihara,T.Ueda,N.Nakabayashi,Polym.J.22(1990)355.

[23]Y.Iwasaki,A.Mikami,K.Kurita,N.Yui,K.Ishihara,N.Nakabayashi,J.

Biomed.Mater.Res.36(1997)508.

[24]K.Ishihara,H.Nomura,T.Mihara,K.Kurita,Y.Iwasaki,N.Nakabayashi,

J.Biomed.Mater.Res.39(1998)323.

[25]G.H.Hsiue,S.D.Lee,P.C.Chang,C.Y.Kao,J.Biomed.Mater.Res.42

(1998)134.

[26]K.Yao,X.D.Huang,X.J.Huang,Z.K.Xu,J.Biomed.Mater.Res.78A

(2006)684.

[27]S.Lee,J.V oros,Langmuir21(2005)11957.

[28]K.Matyjaszewski,T.P.Davis,Handbook of Radical Polymerization,

Wiley–Interscience,Hoboken,2002.

[29]J.-S.Wang,K.Matyjaszewski,J.Am.Chem.Soc.117(1995)5614.

[30]T.E.Pattern,J.Xia,T.Abernathy,K.Matyjaszewski,Science272(1996)

866.

[31]K.Matyjaszewski,J.Xia,Chem.Rev.101(2001)2921.

[32]M.Kamigaito,T.Ando,M.Sawamoto,Chem.Rev.101(2001)3689.

[33]M.Arotc¨u ar′e na,B.Heise,S.Ishaya,https://www.wendangku.net/doc/5513282958.html,schewsky,J.Am.Chem.Soc.

124(2002)3787.

[34]Y.Mitsukami,M.S.Donovan,A.B.Lowe,C.L.McCormick,Macro-

molecules34(2001)2248.

[35]S.Yusa,K.Fukuda,T.Yamamoto,K.Ishihara,Y.Morishima,Biomacro-

molecules6(2005)663.

[36]R.Iwata,P.Suk-In,V.P.Hoven,A.Takahara,K.Akiyoshi,Y.Iwasaki,

Biomacromolecules5(2004)2308.

[37]H.Chen,Z.Zhang,Y.Chen,M.A.Brook,H.Sheardown,Biomaterials26

(2005)2391.

[38]L.J.Suggs,J.L.West,A.G.Mikos,Biomaterials20(1999)683.

[39]K.Matyjaszewski,J.Xia,Chem.Rev.101(2001)2921.

[40]J.Pyun,K.Matyjaszewski,Chem.Mater.13(2001)3436.

[41]A.Favier,M.T.Charreyre,https://www.wendangku.net/doc/5513282958.html,mun.27(2006)

653.

[42]Y.Ma,Y.Tang,N.C.Billingham,S.P.Armes,A.L.Lewis,A.W.Lloyd,J.P.

Salvage,Macromolecules36(2003)3475.

236Y.Iwasaki et al./Colloids and Surfaces B:Biointerfaces 57 (2007) 226–236

[43]Y.T.Li,Y.Q.Tang,R.Narain,A.L.Lewis,S.P.Armes,Langmuir21(2005)

9946.

[44]J.Du,Y.Tang,A.L.Lewis,S.P.Armes,J.Am.Chem.Soc.127(2005)

17982.

[45]Y.Inoue,J.Watanabe,S.Yusa,K.Ishihara,J.Polym.Sci.Pol.Chem.43

(2005)6073.

[46]Y.Iwasaki,K.Akiyoshi,Macromolecules37(2004)7637.

[47]Y.Iwasaki,K.Akiyoshi,Biomacromolecules7(2006)1433.

[48]K.Sugiyama,K.Shiraishi,K.Okada,O.Matsuo,Polym.J.31(1999)883.[49]J.R.Foy,P.F.Williams III,G.L.Powell,K.Ishihara,N.Nakabayashi,M.

LaBerge,Proc.Inst.Mech.Eng.[H]213(1999)5.

[50]S.Lee,N.D.Spencer,Tribo.Int.38(2005)922.

[51]T.Moro,Y.Takatori,K.Ishihara,T.Konno,Y.Takigawa,T.Matsushita,

U.I.Chung,K.Nakamura,H.Kawaguchi,Nat.Mater.3(2004)829. [52]K.Ishihara,N.P.Ziats,B.P.Tierney,N.Nakabayashi,J.M.Anderson,J.

Biomed.Mater.Res.25(1991)1397.

[53]W.Feng,J.L.Brash,S.Zhu,J.Polym.Sci.Pol.Chem.42(2004)2931.

[54]W.Feng,J.L.Brash,S.Zhu,Biomaterials27(2006)847.

高分子相对分子量的测定

高分子分子量的主要测定方法 用途 高聚物的分子量及分子量分布,是研究聚合物及高分子材料性能的最基本数据之一。它涉及到高分子材料及其制品的力学性能,高聚物的流变性质,聚合物加工性能和加工条件的选择。也是在高分子化学、高分子物理领域对具体聚合反应,具体聚合物的结构研究所需的基本数据之一。 表征方法及原理 1.粘度法测相对分子量(粘均分子量Mη) 用乌式粘度计,测高分子稀释溶液的特性粘数[η],根据Mark-Houwink公式[η]=kMα,从文献或有关手册查出k、α值,计算出高分子的分子量。其中,k、α值因所用溶剂的不同及实验温度的不同而具有不同数值。 2.小角激光光散射法测重均分子量(Mw) 当入射光电磁波通过介质时,使介质中的小粒子(如高分子)中的电子产生强迫振动,从而产生二次波源向各方向发射与振荡电场(入射光电磁波)同样频率的散射光波。这种散射波的强弱和小粒子(高分子)中的偶极子数量相关,即和该高分子的质量或摩尔质量有关。根据上述原理,使用激光光散射仪对高分子稀溶液测定和入射光呈小角度(2℃-7℃)时的散射光强度,从而计算出稀溶液中高分子的绝对重均分子量(MW)值。采用动态光散射的测定可以测定粒子(高分子)的流体力学半径的分布,进而计算得到高分子分子量的分布曲线。 3.体积排除色谱法(SES)(也称凝胶渗透色谱法(GPC)) 当高分子溶液通过填充有特种多孔性填料的柱子时,溶液中高分子因其分子量的不同,而呈现不同大小的流体力学体积。柱子的填充料表面和内部存在着各种大小不同的孔洞和通道,当被检测的高分子溶液随着淋洗液引入柱子后,高分子溶质即向填料内部孔洞渗透,渗透的程度和高分子体积的大小有关。大于填料孔洞直径的高分子只能穿行于填料的颗粒之间,因此将首先被淋洗液带出柱子,而其他分子体积小于填料孔洞的高分子,则可以在填料孔洞内滞留,分子体积越小,则在填料内可滞留的孔洞越多,因此被淋洗出来的时间越长。按此原理,用相关凝胶渗透色谱仪,可以得到聚合物中分子量分布曲线。配合不同组分高分子的质谱分析,可得到不同组分高分子的绝对分子量。用已知分子量的高分子对上述分子量分布曲线进行分子量标定,可得到各组分的相对分子量。由于不同高分子在溶剂中的溶解温度不同,有时需在较高温度下才能制成高分子溶液,这时GPC柱子需在较高温度下工作。 4.质谱法 质谱法是精确测定物质分子量的一种方法,质谱测定的分子量给出的是分子质量m对电荷数Z之比,即质荷比(m/Z)过去的质谱难于测定高分子的分子量,但近20余年由于我的离子化技术的发展,使得质谱可用于测定分子量高达百万的高分子化合物。这些新的离子化技术包括场解吸技术(FD),快离子或原子轰击技术(FIB或FAB),基质辅助激光解吸技术(MALDI-TOF MS)和电喷雾离子化技术(ESI-MS)。由激光解吸电离技术和离子化飞行时间质谱相结合而构成的仪器称为“基质辅助激光解吸-离子化飞行时间质谱”(MALDI-TOF MS 激光质谱)可测量分子量分布比较窄的高分子的重均分子量(Mw)。由电喷雾电离技术和离子阱质谱相结合而构成的仪器称为“电喷雾离子阱质谱”(ESI- ITMS 电喷雾质谱)。可测量高分子的重均分子量(Mw)。

实验二氧化碳分子量的测定

实验二氧化碳分子量的 测定 TTA standardization office【TTA 5AB- TTAK 08- TTA 2C】

实验二氧化碳相对分子量的测定 实验目的 1、学习气体相对密度法测定分子量的原理、加深理解理想气体状态方程式和阿佛加德罗定律。 2、掌握二氧化碳分子量的测定和计算方法 3、进一步练习使用启普气体发生器和电子天平称量的操作。 实验原理 1、阿佛加得罗定律:同温、同压、同体积的气体含有相同的分子数,即摩尔数相同。根据阿佛加德罗定 律,只要在同温、同压下,比较同体积的两种气体(设其中之一的分子量为巳知)的质量,即可测定气态 物质的分子量。 本实验是把同体积的二氧化碳气体与空气(其平均分子量为相比,此时有: m空气/ M空气 = m CO2 / M CO2, 即 M CO2= m CO2·M空气/ m空气其中, M空气= 2、理想气体状态方程 PV=n R T 3、制备二氧化碳 反应方程式: CaCO3+2HCl=CaCl2+CO2+H2O 因为大理石中含有硫,所以在气体发生过程中有硫化氢、酸雾、水汽产生。此时可通过硫酸铜溶液,碳酸氢钠溶液以及无水氯化钙除去硫化氢,酸雾和水汽。 实验内容 1、二氧化碳的制取、收集和净化 2、第一次称量 取一个洁净而干燥的锥形瓶,选一个合适的瓶塞塞入瓶口,并在塞子上做一记号,以固定塞子塞入瓶口的位置,在电子天平上称量质量m A:m A=m空气+m锥形瓶+m瓶塞 3、收集二氧化碳 在启普发生器中产生二氧化碳气体,经过净化、干燥后导入锥形瓶中。由于二氧化碳气体略重于空气,所以必须把导管伸入瓶底。收集满气体后,轻轻取出导气管,用塞子塞住瓶口(应与原来塞入瓶 口的位置相同)。 4、第二次称量: 在电子天平上称量二氧化碳、锥形瓶、瓶塞总质量m1: m1=m co2+m锥形瓶+m瓶塞 5、平行称量重复3、4步操作,得m2 m2=m co2+m锥形瓶+m瓶塞 6、将4、5的称量值即m1、m2求平均值m B。 m B= m co2平均+m锥形瓶+m瓶塞 7、在锥形瓶内装满水,塞好瓶塞,注意橡皮塞进入的高度与记号相齐。 8、第四次称量 在台秤上称取水+锥形瓶+瓶塞的质量为 m c: m c=m水+m锥形瓶+m瓶塞 数据处理 根据阿佛加得罗定律: m空气/ M空气 = m CO2 / M CO2, 即 M CO2=m CO2·M空气/ m空气 其中, M空气= 即 M CO2= .m CO2/ m空气 (1) 那么, m空气=?

分子量及分子量分布检测方法

分子量及分子量分布检测方法 1 范围 本标准规定了用高效体积排阻色谱法(HPSEC)测定可溶性聚乳酸平均分子量(Mw)和分子量分布的方法。 本标准适用于外科植入物用,能被三氯甲烷(或其他溶剂)完全溶解的包括聚(L-乳酸)树脂(或缩写PLLA)、聚(D-乳酸)树脂(或缩写PDLA)、任何比率的DL型共聚体以及丙交酯(或缩写PLA)和丙交酯-乙交酯共聚物(或缩写PLGA)的材料。 注1:本方法不是绝对的方法,要求使用市售窄分子量分布聚苯乙烯标准物质进行校正。 注2:由于聚乳酸产品在生产加工及灭菌过程中(特别是辐照灭菌),会影响材料本身的分子量及分子量分布,因此在评价产品时,宜采用成品进行检测。 2 规范性引用文件 下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。 GB/T 2035-2008 塑料术语及定义 3 术语、定义 GB/T 2035-2008界定的以及下列术语和定义适用于本文件 3.1 聚乳酸 polylactic acid,PLA 包括聚(L-乳酸)树脂(或缩写PLLA)、聚(D-乳酸)树脂(或缩写PDLA)。 3.2 丙交酯-乙交脂共聚物 polylactic acid- polyglycolide acid copolymer,PLGA 由丙交酯及乙交脂按一定比例共聚得到的高分子化合物。 4 方法概要 溶解于溶剂的聚乳酸样品注入填有固体基质的色谱柱,按照溶液中聚合物分子大小顺序分离。自进样开始检测器持续监测从柱中出来的洗脱时间,从柱中流出分子按照尺寸分离,并按照其浓度分离的分子量被检测和记录。通过校正曲线,洗脱时间可以转为分子量,样品的各种分子量参数可由分子量/浓度数据计算得出。 5 试剂和材料 5.1 溶剂:本方法推荐使用三氯甲烷(CHCl3)。任何与HPSEC系统组分和柱填料相容的溶剂,并且可溶解聚乳酸样品的溶剂均可以考虑使用。选择溶剂应考虑试剂的纯度和一致性,例如四氢呋喃易与氧气

高聚物相对分子量测定方法

高聚物相对分子量测定方法 高聚物的分子量及分子量分布,是研究聚合物及高分子材料性能的最基本数据之一。它涉及到高分子材料及其制品的力学性能,高聚物的流变性质,聚合物加工性能和加工条件的选择。是在高分子化学、高分子物理领域对具体聚合反应,具体聚合物的结构研究所需的基本数据之一。科标分析实验室科研团队集成多名资深行业专家,拥有博士、硕士等高学历人才数名,提供专业分子量测定服务,为客户提供检测数据,检测方法,检测图谱等论文需要的资料。 (1)端基分析法(end-group analysis,简称EA) 如果线形高分子的化学结构明确而且链端带有可以用化学方法(如滴定)或物理方法(如放射性同位素测定)分析的基团,那么测定一定重量高聚物中端基的数目,即可用下式求得试样的数均相对分子质量。 式中:m-试样质量;Z-每条链上待测端基的数目;n-被测端基的摩尔数。 如果用其他方法测得,反过来可求出Z,对于支化高分子,支链数目应为Z-1。 (2)沸点升高和冰点降低法(boiling-point elevation,freezing-point depression) 利用稀溶液的依数性测定溶质相对分子质量的方法是经典的物理化学方法。对于高分子稀溶液,只有在无限稀的情况下才符合理想溶液的规律,因而必须在多个浓度下测ΔT b(沸点升高值)或ΔT f(冰点下降值),然后以ΔT/C对C作图,外推到c->0时的值来计算相对分子质量。 式中:A2称第二维里系数。 (3)膜渗透压法(osmometry,简称OS)

当高分子溶液与纯溶剂倍半透膜隔开时,由于膜两边的化学位不等,发生了纯溶剂向高分子溶液的渗透。当渗透达到平衡时,纯溶剂的化学位应与溶液中溶剂的化学位相等,即 或 由Floy-Huggins理论,从Δμ1的表达式可以得到 由于C2项很小,可忽略, 式中:χ) A2表征了高分子与溶剂相互作用程度的大小。 对于良溶剂,χ1; 对于θ溶剂,χ1; 对于非溶剂,χ1

高聚物的分子量及其表征

高聚物的分子量及其表征 李杰 (中国矿业大学材料学院,江苏徐州 2210008) 摘 要:介绍高聚物分子量的基本知识和基本测定方法,比较不同的测定方法的特点。 关键词:高聚物 高聚物的分子量 分子量的测定 0.引言 高聚物分子量是研究高分子化合物结构与性能的重要参量, 也是指导生产和科研、控制产品质量帕主要依据。所以,高聚物分子量的测定和表征有及其重要的作用和意义。 高聚物是一种具有多分散性的物质,即即使是一种“纯粹”的高聚物,也会由化学组成相同,分子量不等,结构相似的同系聚合物混合所成,这种高分散性的分子量称为高聚物的多分散性。由于高聚物具有多分散性,所以决定高聚物分子量的测量和表征将不同于传统的无机材料。 由于高聚物是通过复杂的聚合反应产生的,分子链长短不一,相对分子量各个不同,故不可能找到一个单一的原子量代表我们测定和表征的材料中各个分子的分子量。在这里需要对高聚物的分子量从新进行定义。因为在一定情况下高聚物的平均分子量能够反应高聚物的大部分性能,我们通常有平均分子量来表征高聚物的分子量。通常定义有3中不同的高聚物的分子量:1.数均相对分子量n M ,2.重均相对分子量w M ,3.Z 均相对分子量z M ,4.粘均相对分子量M 。 1.基本概念 定义:

()n M M M dM ?∞ =? 200 ()/()w M M M dM M M dM ??∞ ∞=?? 2200 ()/()z M M M dM M M dM ??∞ ∞=?? 11/0 (())n M M M dM αα∞ +=? 式中,()M ?位归一化的相对分子质量数量分布密度函数;α是粘度公式[]KM αη=中的指数,α值在0.5-1之间。 2.分子量的测量 测定高聚物材料的平均相对分子量的方法很多。除化学法(端基分析法)外,大多利用稀溶液各种性质与相对分子质量的关系来测定。其中有热力学法(膜渗透压法、蒸汽压法、沸点升高法和冰点下降法等)、动力学法(粘度法、超速离心沉降法)和光学法(光散射法),此外,还有凝胶渗透色谱法(GPC 法),该方法通过测定高聚物分子相对分子质量分布求得平均相对分子质量。 段及分析法 分析高分子的末端基,用于计算高分子的数均分子量,解释聚合反应的机理。如高分子结构已知,末端基官能团(如羧基、羟基、氨基和乙酰基等)明确,并可用化学法定量分析,则可按下式计算数均分子量:M n =Z/Ne 。式中Z 为每个分子链上所含可分析的基团数;N e 为每克试样中所含端基的摩尔数。分子量低者,单位重量相对端基数多,分析精确度高,适用于测定分子量在数万以下的样品。用放射性

粘度法测定聚合物的分子量

实验十 粘度法测定聚合物的分子量 一、 实验目的 掌握用乌氏粘度计测定高分子溶液粘度的方法并计算粘均分子量M η。 二、 实验原理 高分子溶液具有比纯溶剂高得多的粘度,其粘度大小与高聚物分子的大小、形状、溶剂性质以及溶液运动时大分子的取向等因素有关。因此,利用高分子粘度法测定高聚物的分子量基于以下经验式: Mark 经验式: 式中:[η]-特性粘数 M -粘均分子量 K -比例常数 α-与分子形状有关的经验参数 K 和α值与温度、聚合物、溶剂性质有关,也和分子量大小有关。K 值受温度的影响较明显,而α值主要取决于高分子线团在某温度下,某溶剂中舒展的程度,其数值介于0.5~1之间。K 与α的数值可通过其它绝对方法确定,例如渗透压法、光散射法等,从粘度法只能测定得[η]。 粘度除与分子量有密切关系外,对溶液浓度也有很大的依赖性,故实验中首先要消除浓度对粘度的影响,常以如下两个经验公式表达粘度对浓度的依赖关系: []α ηKM =(10-2) (10-3) (10-1)

式中:r η-相对粘度 sp η-增比粘度 sp η/c -比浓粘度 c -溶液浓度 βκ,-均为常数 1-=r sp ηη (10-5) 式中:t -溶液流出时间,0t -纯溶剂流出时间 显然 ][η即是聚合物溶液的特性粘数,和浓度无关,由此可知,若以c sp /η和 c sp /ln η分别对c 作图,则它们外推到 0→c 的截距应重合于一点,其值等于][η。 ln r ηsp C η或 C 图1 外推法求[η]值 图10-1 外推法求][η值 三、仪器和试剂 试剂:聚乙烯醇,蒸馏水 []c c r c sp c ηηηln lim lim 0 →→==(10-4) (10-6)

高聚物分子量及其分布测定技术

高聚物分子量及其分布测定技术 郑伟国 中国民航学院理学院,天津 300300 weiguozhejiang@https://www.wendangku.net/doc/5513282958.html, 摘 要:研究高聚物分子量及其分布对洞察其聚合机理、裂解机理、溶液性 质、力学性质和加工性能等具有重要的理论和现实意义。本文综述并评价了目 前国内外高聚物分子量及其分布研究领域的主要技术。 关键词:数均分子量 重均分子量 Z 均分子量 粘均分子量 高聚物的分子量有两个基本特征:一是分子量大;二是具有多分散性,即同一种聚合物, 其分子量的大小可以各不相同[1]。因此,讨论某一种聚合物的分子量有多大并无意义,只有 讨论其平均分子量才具有应用价值。根据统计方法的不同,聚合物的平均分子量存在多种不同形式。常用的有数均分子量n M 、重均分子量w M 和粘均分子量ηM n M 和Z均分子量。我们用/表示分子量分布宽度,称为分子量分布指数w M n M [2] 。/越大,说明分子量分布越宽。 w M 当外界条件固定时,可应用聚合物的性质与分子量成函数关系这一特性,来测定其分子量的统计平均值。由于聚合物的不同性质与分子量有不同的依赖关系,因而根据不同的测试手段获得的分子量的平均值是不同的。即如果所用的测定方法不同,就要采用不同的统计平均方法。具体如下: 数均分子量:端基分析法、沸点升高法、冰点降低法、膜渗透压法(MO )、气相渗透压法(VPO ); 重均分子量:光散射法、小角激光光散射法(LALLS )、凝胶色谱法、超速离心沉降平衡法; Z均分子量:超速离心沉降速率法、凝胶渗透色谱法(GPC ); 粘均分子量:粘度法。 1.高聚物数均分子量及其分布的测定 1.1 端基分析法[3] 测定范围:用于相对分子量小于2×104的高聚物分子量的测定,是一种绝对法。 适用对象:适用于线形高聚物分子量的测定,也可用于测定聚合物的支链数目。 优点:操作简便,快捷,结果准确。 计算公式:t t n xw x n w M ==/.其中为聚合物的质量(克),n w t 表示试样中被分析的端基的摩尔数,x 代表高聚物中含被分析端基的个数。 - 1 -

分子量测试的方法

在如今的社会上我们知道任何事情都有两面性,做任何事情都不只一种方法。像分子量测试更不可能只有一种方法的。毕竟多种方法进行测试最终将数据汇总可以减小测试的误差,使结果更加准确。下面我们来看看其测试有哪些方法。 1、凝胶渗透色谱法(GPC),也叫做体积排阻色谱法,是一种新型的液相色谱。它是根据溶质分子尺寸(分子量、有效体积、流体力学体积)的差别在装有多孔凝胶物质的凝胶色谱柱中进行分离,检测系统对分离出来的每部分进行分析,测定各级别的分子量。GPC测定高聚物分子量及分子量分布是目前常用的方法。GPC测试分子量需要知道一个标准样品的流出体积与分子量的关系,因此此方法测试的是相对分子量。 2、端基分析法。其原理就是线型聚合物的化学结构明确,而且分子链端带有可供定量化学分析的基团,则测定链段基团的数目,就可确定已知重量样品中的大分子链数目。用端基分析法测得的是数均

分子量。它对缩聚物的分子量测定应用较广。 3、膜渗透压法。采用一个半透膜将溶液与溶剂隔开,半透膜是一种只允许溶剂分子透过而不允许溶质分子透过的膜。开始时,两池液面高度相等,因为纯溶剂蒸汽压大于溶液蒸汽压,所以纯溶剂向左渗透,直至两侧蒸汽压相等,渗透达平衡。此时半透膜两边的压力差Π叫做渗透压。它测得的分子量是数均分子量M你,而且绝对分子量。这是因为溶液的渗透压是各种不同分子量的大分子共同贡献的。 4、沸点升高和冰点降低。由于溶液中溶剂的蒸汽压低于纯溶剂的蒸汽压,所以溶液的沸点高于纯溶剂的沸点,溶液的冰点低于纯溶剂的冰点。 5、粘度法。聚合物的稀溶液,仍有较大的粘度,其粘度与分子量有关。因此可利用这一特性测定聚合物的分子量。在所有的聚合物分子量的测定方法中,粘度法尽管是一种相对的方法,但因其仪器设备简单,操作方便,分子量适用范围大,又有相当好的实验精确度,

最新粘度法测定高聚物的分子量及其相关知识点

粘度法测定高聚物的分子量 [适用对象]药学、药物制剂、中药学、制药工程、中药学(国际交流方向)、生物工程专业[实验学时] 4学时 一、实验目的 1、掌握粘度法测定高聚物相对分子质量的原理。 2、用乌氏粘度计测定聚乙烯醇的特性粘度,计算聚乙烯醇的粘均相对分子质量。 二、实验原理 单体分子经加聚或缩聚过程便可合成高聚物。并非高聚物每个分子的大小都相同,即聚合度不一定相同,所以高聚物摩尔质量是一个统计平均值。对于聚合和解聚过程的机理和动力学的研究,以及为了改良和控制高聚物产品的性能,高聚物摩尔质量是必须掌握的重要数据之一。 高聚物溶液的特点是粘度特别大,原因在于其分子链长度远大于溶剂分子,加上溶剂化作用,使其在流动时受到较大的内摩擦阻力。 粘性液体在流动过程中,必须克服内摩擦阻力而做功。其所受阻力的大小可用粘度系数η(简称粘度)来表示(kg·m-1·s-1)。 高聚物稀溶液的粘度是液体流动时内摩擦力大小的反映。纯溶剂粘度反映了溶剂分子间的内摩擦力,记作η0,高聚物溶液的粘度则是高聚物分子间的内摩擦、高聚物分子与溶剂分子间的内摩擦以及η η>η0,相对于溶剂,溶液粘度增加0三者之和。在相同温度下,通常 的分数称为增比粘度,记作ηsp,即 ηsp=(η-η0)/η0

而溶液粘度与纯溶剂粘度的比值称作相对粘度,记作ηr ,即 ηr =η/η0 ηr 反映的也是溶液的粘度行为,而ηsp 则意味着已扣除了溶剂分 子间的内摩擦效应,仅反映了高聚物分子与溶剂分子间和高聚物分子间的内摩擦效应。 高聚物溶液的增比粘度ηsp 往往随质量浓度C 的增加而增加。为了 便于比较,将单位浓度下所显示的增比粘度ηsp /C 称为比浓粘度, 而1n ηr /C 则称为比浓粘度。当溶液无限稀释时,高聚物分子彼此相 隔甚远,它们的相互作用可忽略,此时有关系式 [η]称为特性粘度,它反映的是无限稀释溶液中高聚物分子与溶剂分子间的内摩擦,其值取决于溶剂的性质及高聚物分子的大小和形态。由于ηr 和η sp 均是无因次量,所以[η]的单位是质量浓度C 单位的倒数。 在足够稀的高聚物溶液里,ηsp /C 与C 和ln ηr /C 与C 之间分别符 合下述经验关系式: ηsp /C=[η]+κ[η]2C ln ηr /C=[η]-β[η]2C 上两式中κ和β分别称为Huggins 和 Kramer 常数。这是两直线方程,通过ηsp /C 对C 或ln ηr /C 对C 作图,外推至C=0时所 得截距即为[η]。显然,对于同一高聚物, 由两线性方程作图外推所得截距交于同一点,如右图所示。 ηsp /C 或ln ηr /C []ηηη==→→c c r c sp c ln lim lim 00

第四、五章 高聚物的分子量及分子量分布

第四、五章 高聚物的分子量及分子量分布 1 已知某聚合物的特性粘度与分子量符合5.003.0M =η式,并有4110=M 和5210=M 两单分散级分。现将两种级分混合,欲分别获得000,55=n M 和000,55=w M 及000,55=ηM 的三种试样。试求每种试样中两个级分的重量分数应取多少? 解:设需104级分的重量分数为x W ,则105级分的重量分数为x W -1 第一种试样: ∑= i i i n M W M 1 即 5 4101101 55000x x W W -+= 91.0,09.0)10()10(54=≈=∴==x x x W W W 第二种试样: ∑=i i i w M W M 即 5410)1(1055000?-+?=x x W W 5.0=∴x W ,即104与105各取一半重量。 第三种试样: a i a i M W M 1 ?? ? ??=∑η 即 25.055.04]10)1(10[55000???-+?=W W 65.0,35.0)10()10(54==∴==x x W W 2 有一个二聚的蛋白质,它是一个有20%解离成单体的平衡体系,当此体系的数均分子量80000时,求它的单体分子量(0M )和平衡体系的重均分子量(w M )各为多少? 解: P —P ) (单体M 0) (二聚体 000,80=n M 由0M 和02M 组成,

由∑∑= i i i i n N M N M 即0 000 002228 .02.0000,80M M M M M M + ?+?= 000,480=∴M 由 00 00200 200 2 228.02.0)2(28 .02.0M M M M M M M M M N M N M i i i i w i i ?+??+?==∑∑ 400,868 .02.0000 ,4828.0000,482.0=+??+?= 3 将分子量分别为105和104的同种聚合物的两个级分混合时,试求: (1)10g 分子量为104 的级分与1g 分子量为105 的级分相混合时,计算n M 、w M 、z M ; (2)10g 分子量为105 的级分与1g 分子量为104 的级分相混合时,计算n M 、w M 、z M ; (3)比较上述两种计算结果,可得出什么结论? 解:(1)890,101011 /11011/101 154 =+== ∑i i i n M W M 180,181011 1 10111054=?+?= =∑i i i w M W M 000,55101101010110105 41082=?+??+?== ∑∑i i i i i i z M W M W M (2) 000,551011 /11011/101 145 =+== ∑i i i n M W M 820,911011 1 10111045=?+?= =∑i i i w M W M 110,99101101010110104 58102=?+??+?== ∑∑i i i i i i z M W M W M

聚合物分子量的测定粘度法

中国石油大学 化学原理Ⅱ实验报告 实验日期: 成绩: 班级: 学号: 姓名: 教师: 同组者: 聚合物分子量的测定——粘度法 一. 实验目的 学会一种测定分子量的方法。 二. 实验原理 由于聚合物具有多分散性,所以聚合物的分子量是一个平均值。有许多测定分子量的方法(如光散射法、渗透压法、超速离心法、端基分析法等),但最简单、而使用范围又广的是粘度法。由粘度法测得的聚合物的分子量叫粘均分子量,以“V M ”表示。粘度法又分多点法和一点法: 1. 多点法 多点法测定聚合物粘均分子量的计算依据是: [][] , V V kM k M αηηα=---式中: 特性粘数;与温度和溶剂有关的常数; 聚合物的粘均分子量。 若设溶剂的粘度为η0,聚合物溶液浓度为c (100mL 所含聚合物的克数表示)时的粘度为η,则聚合物溶液粘度与浓度间有如下关系: 20020[][]ln ln [][]SP r k c c c c c c ηηηηηηηηηηβη-==+==+ 以/SP c η,ln /r c η对c 作图,外推直线至c 为0求[η],即: 00ln []lim lim SP r c c c c ηηη→→== 由于k 、α是与温度、溶剂有关的常数,所以对一定温度和特定的溶剂,k 、α有确定的数值。 因此,只要测定不同浓度下聚合物溶液的粘度,即可通过数据处理,求出聚合物的粘均分子量V M 。 2. 单点法 对低浓度的聚合物溶液,其特性粘数可由下式计算:

1[](ln )2r SP c ηηη= + 实验时,只要测定一个低浓度的聚合物溶液的相对粘度,即可求得所测试样的特性粘数。 本实验采用乌氏粘度计测定聚合物溶液在不同浓度下的粘度。 三. 仪器与药品 1. 仪器 乌氏粘度计,秒表,吸耳球,恒温箱,移液管,容量瓶。 2. 药品 聚丙烯酰胺(工业品),硝酸钠(分析纯),蒸馏水。 四. 实验步骤 1. 测定溶液的t 0 用移液管移取20mol/L 硝酸钠溶液由支管3 加到已洗净、烘干的粘度计的球9 中,然后将粘度计固定在已调至30℃的恒温槽中,恒温约15min ,即可按下述方法测定: ①用左手的拇指和中指将粘度计的支管1 捏住,用食指将支管1 的管口堵住; ②用洗耳球从支管2 的管口将溶液吸至刻度4 以上的粗直径部分,在将食指松开的同时将洗耳球从管口移开,这时球8 中的溶液因支管1 通大气即迅速流回球9,而支管2 中的刻度4以上的溶液则通过毛细管7 慢慢流回球9,用秒表测定溶液液面经过刻度4 与6 所需要的时间; ③重复数次,取平均值,作为1mol/L 硝酸钠溶液的液面流经粘度计4 与6 两刻度的时间t 0。 ④测定后,将粘度计的溶液倒出,先后用自来水、蒸馏水洗净,然后烘干、备用。 2. 测定不同浓度的聚丙烯酰胺溶液的t ①用移液管将10mL 浓度为0.4g/100mL 的聚丙烯酰胺溶液和10mL 2mol/L 硝酸钠经支管3 加入已洗净、烘干的粘度计的球9 中。 ②摇动球9,使加入的溶液均匀混合。然后将粘度计固定在30℃的恒温槽中,恒温约15min 后,用上述方法测定聚丙烯酰胺溶液的液面流经4 与6 两刻度间的时间t 1。 ③用同样的方法,依次向球9 加入10mL 、10mL 、20mL 、20mL 、1mol/L 硝酸钠溶液进行稀释,每稀释一次,都要摇匀,并测该浓度的聚丙烯酰胺溶液的液面流经4 与6 两刻度的时间。由此得t 2、t 3、t 4、t 5。 ④全部测定结束后,将球9 的溶液倒出,先后用自来水、蒸馏水洗净,然后烘干,备下次使用。 五. 结果处理 计算各溶液的浓度c 、00SP c t t ct η-()即、0ln(/)ln r t t c c η(即)的数值。 实验中记录的数据如下:

光散射法测定聚合物的重均分子量及分子尺寸

实验三光散射法测定聚合物的重均分子量及分子尺寸 光散射法是一种高聚物分子量测定的绝对方法,它的测定下限可达5×103,上限为107。光散射一次测定可得到重均分子量、均方半径、第二维利系数等多个数据,因此在高分子研究中占有重要地位,对高分子电解质在溶液中的形态研究也是一个有力的工具。 一、实验目的 1.了解光散射法测定聚合物重均分子量的原理及实验技术。 M、均方末端2.用Zimm双外推作图法处理实验数据。并计算试样的重均分子量 w 距2h及第二维利系数2A。 二、基本原理 一束光通过介质时,在入射光方向以外的各个方向也能观察到光强的现象称为光散射现象。光波的电场振动频率很高,约为1015/s数量级,而原子核的质量大,无法跟着电场进行振动,这样被迫振动的电子就成为二次波源,向各个方向发射电磁波,也就是散射光。因此,散射光是二次发射光波。介质的散射光强应是各个散射质点的散射光波幅的加和。光散射法研究高聚物的溶液性质时,溶液浓度比较稀,分子间距离较大,一般情况下不产生分子之间的散射光的外干涉。若从分子中某一部分发出的散射光与从同一分子的另一部分发出的散射光相互干涉,称为干涉。假若溶质分子尺寸比光波波长小得多时(即≤1/20λ,λ是光波在介质里的波长),溶质分子之间的距离比较大,各个散射质点所产生的散射光波是不相干的;假如溶质分子的尺寸与入射光在介质里的波长处于同一个数量级时,那末同一溶质分子各散 图3-1 射质点所产生的散射光波就有相互干涉,这种干涉现象是研究大分子尺寸的基础。高分子链各链段所发射的散射光波有干涉作用,这就是高分子链散射光的干涉现

象,见图3-1。 关于光散射,人们提出了升落理论。这个理论认为:光散射现象是由于分子热运动所造成的介质折光指数或介电常数的局部升落所引起的。将单位体积散射介质(介电常数为ε)分成N 个小体积单元,每个单元的体积大大小于入射光在介质里波长的三次方,即 301V N λ?= 但是小体积单元,仍然是足够大的,其中存在的分子数目满足作统计计算的要求。 由于介质折光指数或介电常数的局部升落,介电常数应是εε+?。假如,各小体积单元的局部升落互不相关,在距离散射质点r ,与入射光方向成θ角处的散射光强为(见图3-2) 022_____22 421cos (,)()2i I r V N I r πθθελ?? +=???? ?? ? (1) 上式中λ0为入射光波长;I i 为入射光的光强;_____ 2 ε?是 介电常数增量的平方值;V ?是小体积单元体积;N 为小体积单元数目。 经过一系列推导(较为繁琐,从略),可得光散射计算的基本公式: ___ 2 2 22221cos 181sin 22sin 92KC h A C R M θθπθ θλ??+ ??=++???+ ? ? ?? ---------(2) 式中2 224 04n K n N C πλ??? = ???? (N 为阿佛加德罗常数,n 为溶液折光指数,C 为溶质浓度),R θ为瑞利比,θ为散射角,___2 h 为均方末端距,A 2第二维利系数。 具有多分散体系的高分子溶液的光散射,在极限情况下(即θ→0及C →0)可写成以下两种形式: 2201cos 1 22sin w KC A C R M θθθθ→??+?=+ ? ? ?--------------------------(3) 22___22201cos 181sin 2sin 92w Z C KC h R M θθπθθλ→??????+?=+?? ? ?????????-------------图3-2

粘度法测定聚合物的粘均分子量

粘度法测定聚合物的粘均分子量 一、实验目的 1. 掌握使用粘度法测定聚合物分子量的基本原理 2. 掌握乌氏粘度计测定聚合物稀溶液粘度的实验技术及数据处理方法 3. 分析分子量大小对聚合物性能以及聚合物加工性能的关系及影响。 二、基本原理 聚合物稀溶液的粘度主要反映了液体分子之间因流动或相对运动所产生的内摩擦阻力。内摩擦阻力与聚合物的结构、溶剂的性质、溶液的浓度及温度和压力等因素有关,它的数值越大,表明溶液的粘度越大。 聚合物溶液粘度的变化,一般采用下列的粘度量来描述。 1.相对粘度,又称粘度比,用ηr表示。 它是相同温度条件下,溶液粘度η与纯溶剂粘度η0之比,表示为:ηr=η/η0 (1) 相对粘度是一个无因次量,随着溶液浓度增加而增加。对于低剪切速率下聚合物溶液,其值一般大于1。 2.增比粘度(粘度相对增量),用ηsp表示,是相对于溶剂来说,溶液粘度增加的分数:ηsp =(η-η0)/η0 =ηr –1 (2) 3. 比浓粘度(粘数),对于高分子溶液,粘度相对增量往往随溶液浓度的增加而增大,因此常用其与浓度c之比来表示溶液的粘度,称为比浓粘度或粘数,即:ηsp/c = (ηr-1)/c (3) 粘数的因次是浓度的倒数,一般用 ml/g表示。 比浓对数粘度(对数粘度),其定义是相对粘度(粘度比)的自然对数与浓度之比,即: ( lnηr)/c = [ln(1+ηsp)]/c (4) 单位为浓度的倒数,常用 ml/g表示。 特性粘度(极限粘度),其定义为比浓粘度(粘数)ηsp/c或比浓对数粘度(对数粘度)lnηr/c在无限稀释时的外推值,用[η]表示,即: [η] = lim(ηsp/c) = lim(lnηr/c) (5) c→0c→0 [η] 称为特性粘度(或极限粘数),其值与浓度无关,量纲是浓度的倒数。 实验证明,对于给定聚合物,在给定的溶剂和温度下,[η]的数值仅有试样的分子量Mη所决定。[η]和 Mη的关系如下: [η] =K Mηα (6) 上式称为Mark-Houwink方程。 式中:——扩张因子,与溶液中聚合物分子形态有关; Mη——粘均分子量 (注:一些常用聚合物的K 、α值见附表1所示) K 、α与温度、聚合物种类和溶剂性质有关,K值受温度影响明显,而α值主要取决于高分子线团在溶剂中舒展的程度,一般介于0.5~1.0之间。在一定温度时,对给定的聚合物-溶剂体系,一定的分子量范围内K 、α为常数,[η]只与分子量大小有关。K 、α值可从有关手册中查到(见附表1),或采用几个标准试样又式(6)进行测定,标准试样的分子量有绝对方法(如渗透压法和光散射法)确定。

二氧化碳分子量的测定

实验四 二氧化碳分子量的测定 一、实验目的 1、掌握用密度法测分子量的原理,加深理解气态方程式 2、掌握CO 2分子量测定和计算方法 3、练习使用启普发生器和气体净化装置 4、进一步练习使用台秤和分析天平 5、学习气压计的使用 二、实验原理 同温同压下同体积所含摩尔数相同,所以只要在相同温度和压力下,测定相同体积的两种气体的质量,其中一种气体的质量已知,即可求得另一种气体的分子量。 M 2CO = 空 w w CO 2×29.0 (空气的平均分子量为29) 三、实验内容与步骤 1、安装装置(启普发生器及气体净化、干燥装置) (1)装配——在球形漏斗颈部及活塞处均应涂上凡士林 ,插好球形漏斗和玻璃旋塞,转动几次,使装配严密。 (2)查气密性——开启旋塞,从球形漏斗口注水至充满半球体时,关闭旋塞。继续加水,待水从漏斗管上升到漏斗球体内,停止加水。在水面处做一记号,静置片刻,如水面不下降,证明不漏气,可以使用。 (3)加试剂——在葫芦状容器的狭窄处垫一些玻璃棉,再加入块状或较大颗粒的固体试剂后,装上气体逸出管。固体量不可太多,以不超过中间球体容积的1/3为宜。液体从球形漏斗中加入,通过调节气体逸出导管上的活塞,可控制气体流速。 (4)发生气体——使用时,打开活塞即可。停止使用时,关闭气体逸出导管的活塞,气体的压力使液体与固体分离即使反应停止发生;打开活塞,气体又重新产生。 (5)添加或更换试剂——发生器中的酸液长久使用会变稀。换酸液时,可先用塞子将球型漏斗上口紧塞并关上气体导管口,然后把液体出口的塞子拔下,让废液流出,再塞紧塞子,向球型漏斗中加入酸液。需要更换或添加固体时,可把导气管旋塞关好,让酸液压入半球体后,用塞子将球型漏斗上口塞紧,再把装有玻璃旋塞的橡皮塞取下,更换或添加固体。 (6)气体的净化和干燥 1、气体产生的装置 为了得到较纯净的气体,酸雾可用水或玻璃棉除去;水汽可用浓硫酸、无水氯化钙或硅胶吸收(也可用硫酸铜溶液和碳酸氢钠溶液分别代替水和浓硫酸)。一般情况下使用洗气瓶,干燥塔,U 形管或干燥管等仪器进行净化或干燥。液体装在洗气瓶内,无水氯化钙和硅胶装在干燥塔或U 形管或干燥管内。(装置图见实验教材27 图7-1)。该装置

粘度法测定聚合物分子量

粘度法测定聚合物分子量 2010年04月06日11:30 admins 学习时间:20分钟评论 0条分子量是聚合物最基本的结构参数之一,与聚合物材料物理性能有着密切的关系,在理论研究和生产实践中经常需要测定这个参数。测定聚合物分子量的方法很多,不同测定方法所得出的统计平均分子量的意义有所不同,其适应的分子量范围也不相同。对线型聚合物,各测定聚合物分子量的方法适用的范围如表1所示: 表1:测量聚合物分子量的方法与适用分子量范围 方法名称适用摩尔质量范围平均摩尔质量类型方法类型 粘度法104~107 粘均相对法端基分析法<3×104 数均绝对法 沸点升高法<3×104 数均相对法 凝固点降低法<5×103 数均相对法气相渗透压法(VPO) <3×104 数均相对法膜渗透压法2×104~1×106 数均绝对法 光散射法2×104~1×107 重均绝对法超速离心沉降速度法1×104~1×107 各种平均绝对法 超速离心沉降平衡法1×104~1×106 重均、数均绝对法凝胶渗透色谱法1×103~5×106 各种平均相对法在高分子工业和研究工作中最常用的是粘度法,它是一种相对的方法,适用于分子量在104~107范围的聚合物。此法设备简单、操作方便,又有较高的实验精度。通过聚合物体系粘度的测定,除了提供粘均分子量外,还可得到聚合物的无扰链尺寸和膨胀因子,其应用最为广泛。 目的要求 掌握粘度法测定聚合物分子量的基本原理。 掌握用乌氏粘度计测定聚合物稀溶液粘度的实验技术及数据处理方法。 测定线性聚合物-聚苯乙烯的平均分子量 原理 聚合物在良溶剂中充分溶解和分散,其分子链在良溶剂中的构象是无规线团。这样聚合物稀溶液在流动过程中,分子链线团与线团间存在摩擦力,使得溶液表现出比纯溶剂的粘度高。聚合物在稀溶液中的粘度是它在流动过程中所存在的内摩擦的反映,其中溶剂分子相互之间的内摩擦所表现出来的粘度叫做溶剂粘度,以η0表示,粘度的单位为帕斯卡秒。而聚合物分子相互间的内摩擦以及聚合物分子与溶剂分子之间的内摩擦,再加上溶剂分子相互间的摩擦,三者的总和表现为聚合物溶液的粘度,以η表示。聚合物稀溶液的粘度主要反映了分子链线团间因流动或相对运动所产生的内摩擦阻力。分子链线团的密度越大、尺寸越大,则其内摩擦阻力越大,聚合物溶液表现出来的粘度就越大。聚合物溶液的粘度与聚合物的结构、

粘度法测定聚合物的分子量实验报告

实验一 粘度法测定聚合物的分子量 粘度法就是测定聚合物分子量的相对方法。高聚物分子量对高聚物的力学性能、溶解性、 流动性均有极大影响。由于粘度法具有设备简单、操作方便、分子量适用范围广、实验精度 高等优点,在聚合物的生产及科研中得到十分广泛的应用。本实验就是采用乌氏粘度计测定 甲苯溶液中聚苯乙烯粘度,进而测定求出PS 试样分子量。 一、实验目的要求 1、掌握粘度法测定聚合物分子量的实验基本方法。 2、了解粘度法测定聚合物分子量的基本原理。 3、通过测定特性粘度,能够计算PS 的分子量。 二、实验原理 1、粘性液体的牛顿型流动 粘性流体在流动过程中,由于分子间的相互作用,产生了阻碍运动的 内摩擦力,粘度就就是这种内摩擦力的表现。即粘度可以表征粘性液体在流动过程中所受阻 力的大小。 按照牛顿的粘性流动定律,当两层流动液体间由于粘性液体分子间的内摩擦力在其相邻各 流层之间产生流动速度梯度就是(dr dv /),液体对流动的粘性阻力就是:dr dv A F //?η= (1-1) 该式即为牛顿流体定律。 式中, η—液体粘度,单位(Pa ·s);A —平行板面积;F —外力。 符合牛顿流体定律的液体称为牛顿型液体。高分子稀溶液在毛细管中的流动基本属于牛顿 型流动。在测定聚合物的特性粘度[η]时,以毛细管粘度计最为方便。 2、泊肃叶定律 高分子溶液在均匀压力p(即重力ρgh)作用下,流经半径为R 、长度为L 的均匀毛细管,根据 牛顿粘性定律,可以导出泊肃叶公式: LV t ghR 84ρπ=η (1-2) 式中,g —重力加速度;ρ—流体的密度;V —液出体积;t —流出时间。 由于液体在毛细管内流动存在位能,除克服部分内摩擦力外,还会使其获得动能,结果导致 实测值偏低。因此,须对泊肃叶公式作必要的修正: Lt V m LV t ghR πρ-ρπ=η884 (1-3) 式中,m —毛细管两端液体流动有关常数。 若令LV ghR A 84π=;L mV B π=8,式(1-3)可简化为:t B At -=ρη (1-4) 3、聚合物溶液粘度的测定 采用乌氏粘度计测定聚合物溶液的粘度时,常用到以下两个参数: (1)相对粘度 ηη=ηr (1-5)

黏度法测高聚物分子量(最终版)

华 南 师 范 大 学 实 验 报 告 学生姓名 平璐璐 学 号 20132401179 专 业 化学(师范) 年级、班级 13级一班 课程名称 物理化学实验 实验项目 黏度法测定水溶性高聚物分子量 实验类型 □验证□设计□综合 实验时间 2016 年 4 月 7 日 实验指导老师 林晓明 实验评分 一、实验目的 1.测定多糖聚合物-右旋糖苷的平均分子量; 2.掌握用乌式黏度计测定黏度的原理和方法。 二、实验原理 高聚物摩尔质量不仅反映了高聚物分子的大小,而且直接关系到它的物理性能。与一般的无机物或低分子的有机物不同,高聚物多是摩尔质量大小不同的大分子混合物,所以通常所测高聚物的分子量是一种统计的平均分子量。 用粘度法测定的分子量称“黏均分子量”记作M η 高聚物稀溶液的黏度(η)是流体在流动时摩擦力大小的反映,这种流动过程中的内摩擦力主要有:纯溶剂间的内摩擦,也就是纯溶剂的粘度,记作η0,高聚物分子与溶剂分子间的内摩擦,以及高聚物分子间的内摩擦。这三种内摩擦的综合成为高聚物溶液的黏度η 实验证明,在相同温度下,η> η0,相对于溶剂,其溶液粘度增加的分数,称为增比粘 度,记作 sp η, 0sp r 00 11 ηηη ηηηη-= =-=- r η称为相对粘度,即溶液粘度对溶剂粘度的相对值。 高聚物溶液的ηsp 往往随浓度增加而增大,为了便于比较,定义单位浓度的增比黏度ηsp /c 为比浓黏度,定义ln ηsp /c 为比浓对数黏度。当溶液溶液无限稀释,高聚物分子彼此相隔甚远,其相互作用可以忽略不计。此时比浓粘度趋近于一个极限值,即: [η]称为特性粘度,在足够稀的溶液中,比浓黏度ηsp /c 和比浓对数黏度ln ηsp/c 与溶液的浓度有以下的关系(关系公式):

粘度法测定水溶性高聚物分子量实验报告

黏度法测定水溶性高聚物分子量 一.实验目的 1. 测定水溶性高聚物聚乙烯醇的相对分子质量; 2.掌握用乌式黏度计测定黏度的原理和方法。 二.实验原理 高聚物相对分子质量是表征聚合物特征的基本参数之一,本实验采用的右旋糖苷分子是目前公认的优良血浆代用品之一, 由于高聚物分子量大小不一,故通常测定高聚物分子量都是利用统计的平均分子量。常用的测定方法有很多,如粘度法、端基分析、沸点升高、冰点降低、等温蒸馏、超离心沉降 。 及扩散法等,其中,用粘度法测定的分子量称“黏均分子量”,记作M η增比黏度: 特性粘度: 时间与粘度的关系 N=n/n0=t/t0 (3-84) 三、仪器与试剂 恒温槽 1 套乌式黏度计 1支 1/10 秒表 1只聚乙烯醇 四、实验步骤 1.洗涤黏度计 取出一只黏度计,先用丙酮灌入黏度计 中,浸洗去留在黏度计中的高分子物质, 黏度计的毛细管部分,要反复用丙酮流 洗。方法是:用约 10 mL 丙酮至大球中,

并抽吸丙酮经毛细管 3 次以上,洗毕, 倾去丙酮倒入回收瓶中,再重复一次,然 后用吹风机吹干黏度计备用。 2.测定溶剂流出时间 在铁架台上调节好黏度计的垂直度和高度,然后将黏度计安放在恒温水浴中。用移液管吸取10mL 纯水,从A 管注入。于37℃恒温槽中恒温5min。进行测定时,在 C管上套上橡皮管,并用夹子夹住,使其不通气,在 B 管上用橡皮管接针筒,将蒸馏水从 F 球经 D 球、毛细管、E球抽到G球上(不能高出恒温水平面),先拔去针筒并解去夹子,使 C管接通大气,此时 D 球液体即流回 F 球,使毛细管以上液体悬空。毛细管以上液体下流,当液面流经 a刻度时,立即按停表开始记录时间,当液面降到b刻度时,再按停表,测得刻度a、b 之间的液体流经毛细管所需时间,重复操作两次,记录留出时间且误差不大于1-2s,取两次平均值为 t0, 3.溶液流出时间的测定 取出黏度计,倾去其中的水,加入少量的丙酮溶液润洗,经过各个瓶口流出,以达到洗净的目的。同上法安装调节好黏度计,用移液管吸取 10mL 溶液小心注入黏度计(注意不能将溶液黏在黏度计的管壁上),在溶液恒温过程中,应用溶液润洗毛细管后再测定溶液的流出时间t。然后一次分别加入 2.0mL、3.0 mL、5.0 mL、10.0 mL 蒸馏水,按上述方法分别测量不同浓度时的t 值。每次稀释后都要将溶液在F 球中充分搅匀(可用针筒打气的方法,但不要将溶液溅到管壁上),然后用稀释液抽洗黏度计的毛细管、E 球和 G 球,使黏度计各处溶液的浓度相等,而且须恒温。 五、数据处理及结论 1.数据整理(恒温槽温度:37℃) 为了作图方便,假定起始相对浓度是1,根据原理中的公式计算所得数据记录如下表 表一数据记录表