introduction to Hybrid_1

Drivetrains

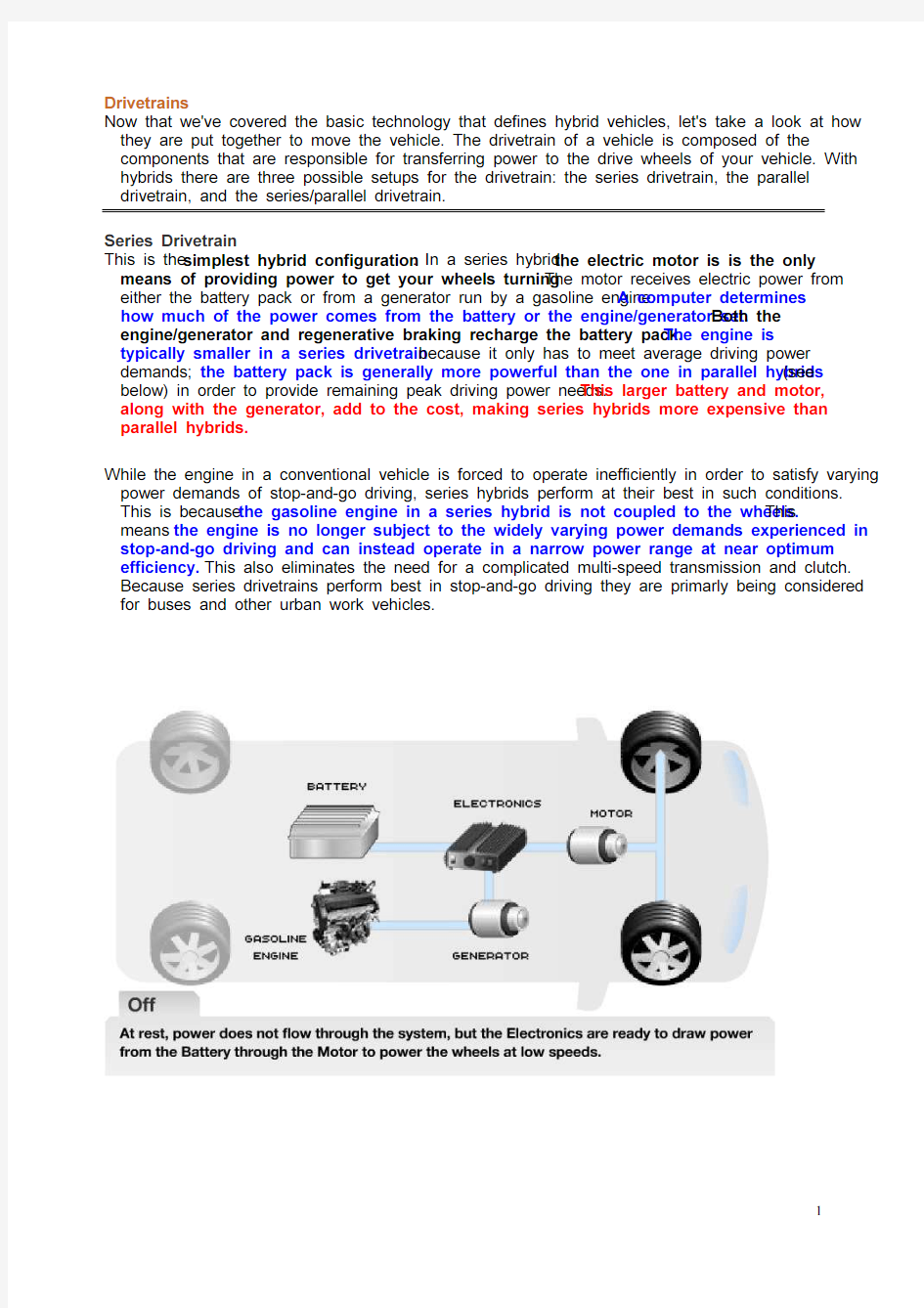

Now that we've covered the basic technology that defines hybrid vehicles, let's take a look at how they are put together to move the vehicle. The drivetrain of a vehicle is composed of the components that are responsible for transferring power to the drive wheels of your vehicle. With hybrids there are three possible setups for the drivetrain: the series drivetrain, the parallel drivetrain, and the series/parallel drivetrain.

Series Drivetrain

This is the simplest hybrid configuration. In a series hybrid, the electric motor is is the only means of providing power to get your wheels turning. The motor receives electric power from either the battery pack or from a generator run by a gasoline engine. A computer determines how much of the power comes from the battery or the engine/generator set.Both the engine/generator and regenerative braking recharge the battery pack.The engine is typically smaller in a series drivetrain because it only has to meet average driving power demands; the battery pack is generally more powerful than the one in parallel hybrids (see below) in order to provide remaining peak driving power needs. This larger battery and motor, along with the generator, add to the cost, making series hybrids more expensive than parallel hybrids.

While the engine in a conventional vehicle is forced to operate inefficiently in order to satisfy varying power demands of stop-and-go driving, series hybrids perform at their best in such conditions. This is because the gasoline engine in a series hybrid is not coupled to the wheels. This means the engine is no longer subject to the widely varying power demands experienced in stop-and-go driving and can instead operate in a narrow power range at near optimum efficiency. This also eliminates the need for a complicated multi-speed transmission and clutch. Because series drivetrains perform best in stop-and-go driving they are primarly being considered for buses and other urban work vehicles.

Parallel Drivetrain

Some up-and-coming hybrid models use a second electric motor to drive the rear wheels, providing electronic all-wheel drive that can improve handling and driving in bad weather conditions.

With a parallel hybrid electric vehicle, both the engine and the electric motor generate the power that drives the wheels. The addition of computer controls and and a transmission allow these components to work together. This is the technology in the Insight, Civic, and Accord hybrids from Honda. Honda calls it their Integrated Motor Assist (IMA) technology. Parallel hybrids can use a smaller battery pack and therefore rely mainly on regenerative braking to keep it recharged. However, when power demands are low, parallel hybrids also utilize the drive motor as a generator for supplemental recharging, much like an alternator in conventional cars.

Since, the engine is connected directly to the wheels in this setup, it eliminates the inefficiency of converting mechanical power to electricity and back, which makes these hybrids quite efficient on the highway. Yet the same direct connection between the engine and the wheels that increases highway efficiency compared to a series hybrid does reduce, but not eliminate, the city driving efficiency benefits (i.e. the engine operates inefficiently in stop-and-go driving because it is forced to meet the associated widely varying power demands).

Series/Parallel Drivetrains

This drivetrain merges the advantages and complications of the parallel and series drivetrains. By combining the two designs, the engine can both drive the wheels directly (as in the parallel drivetrain) and be effectively disconnected from the wheels so that only the electric motor powers the wheels (as in the series drivetrain). The Toyota Prius has made this concept a popular, and a similar technology is also in the new Ford Escape Hybrid. As a result of this dual drivetrain, the engine operates at near optimum efficiency more often.At lower speeds it operates more as a series vehicle, while at high speeds, where the series drivetrain is less efficient, the engine takes over and energy loss is minimized. This system incurs higher costs than a pure parallel hybrid since it needs a generator, a larger battery

pack, and more computing power to control the dual system. However, the series/parallel drivetrain has the potential to perform better than either of the systems alone.

System Complicacy Battery Pack Cost Fuel Economy

City Driving Highway Driving Series Drivetrain Most simple More Powerful than Parallel More

expensive

than Parallel, (lager

battery,

Motor,

Generator) More favourable than Parallel

medium-duty vehicles such as transit buses Parallel Drivetrain complicate Cheaper than other

systems Profitable

than Series Insight, Civic, and

Accord

hybrids from

Honda. Series/Parallel Drivetrain Most

complicate Lager Battery

Package

than

Parallel More expensive than Parallel, (lager Battery,

additional

Generator,

more

Computing

Controll dual

System More favourable than

Parallel Profitable than Series Toyota Prius, Ford Escape

alternative fuels and advanced technology vehicles including:

?Ethanol, Methanol and synthetic fuels

?Biodiesel

?Natural gas

?Propane

?Hybrid and battery-powered electric vehicles

?Hydrogen and fuel cell powered vehicles

A new way of describing hybrids is to categorize them into four groups. These groups are:

?Full Hybrid

?Mild Hybrid

?Power Hybrid

?Micro Hybrid

Full Hybrids

Full hybrids are easiest to describe! A full hybrid is a vehicle that utilizes all of the advantages of hybrid technology.A full hybrid is capable of moving under electric power only.It can drive off without the engine running! Since this feature is normally employed when accelerating from a complete stop (engineers refer to this as the launch mode) a full hybrid will feature electric launch. When driving a full hybrid you must remember that during electric launch your vehicle is completely quiet! This means that pedestrians cannot hear you coming! If you are launching from a busy intersection or anywhere that people are nearby, get into the habit of blowing a few toots on the horn to make pedestrians aware of you!

A full hybrid will also feature regenerative braking. Regenerative braking is that feature which allows the electric traction motor to be electronically converted to a generator. This conversion takes place when the vehicle’s brakes are applied. Much of the kinetic energy of the vehicle is thus converted back into electricity and stored in the batteries for later use rather than simply wasted as heat. A conventional vehicle’s brakes simply convert kinetic energy to heat, and that energy is entirely wasted! Of course, regenerative braking also requires sophisticated electronically controlled braking technology commonly known as brake by wire.

A full hybrid will feature the engine stop or idle stop feature. The hybrid’s electronic control system will shut the internal combustion engine down whenever it is not needed to either assist with driving the wheels or producing electricity to recharge the batteries. This feature is most noticeable when coming to a stop. The tach will drop to 0 RPM and the noise and/or vibration from the engine will cease. The engine will restart as soon as it is needed again, usually several seconds after the vehicle has begun to accelerate. This feature alone is estimated to provide hybrids a 10% to 15% gain in fuel economy over conventional vehicles especially in urban driving conditions. Engine stop combined with regenerative braking are the main reasons why most hybrids actually achieve better fuel economy in city/urban driving than during highway driving! Hybrid drivers will notice how rapidly the engine restarts. The conventional 12-volt starter motor

that has been used to start automobile engines for nearly a century can only spin the engine up to a speed of approximately 250 RPM. The high-voltage integrated starter/generator (ISG) of a hybrid will spin the engine at speed in excess of 900 RPM. This assures an almost instantaneous restart (less than 300 milliseconds) of the hybrid engine.

Finally, a full hybrid will feature a downsized internal combustion engine. A conventional automobile must obtain all of its power from its internal combustion engine. This engine must be sized appropriately to be able to provide adequate acceleration and the ability to climb steep grades. Because a hybrid can call upon the electric traction motor to provide additional power to the wheels when needed, such as during rapid acceleration or climbing steep grades, the internal combustion engine can be downsized. In a hybrid, the internal combustion engine need only be able to supply the average horsepower demand of the vehicle. Use of a smaller engine with energy-efficient operating strategies such as the Atkinson Cycle also helps to improve the efficiency and fuel economy of hybrids. The Ford Escape and Toyota Prius are full hybrids.

Mild Hybrids

Most mild hybrid designs place the electric motor generator between the engine and the transmission. The armature (rotor) of the motor actually replaces the engine flywheel in many designs! Since the internal combustion engine and the electric motor share the same shaft, one cannot turn without the other. This means that a mild hybrid cannot have the electric launch feature of the full hybrid. The electric motor cannot turn the wheels independent of the engine. However, it can include all of the other features of full hybrids-regenerative braking, idle stop, and a downsized engine. The GMC Sierra pickup and Honda Civic/Accord are mild hybrids.

Power Hybrid

A power hybrid is a full hybrid with one exception. A power hybrid does not include a downsized internal combustion engine. Instead, power hybrids provide a large, high horsepower engine and a hybrid drive system to provide even more torque and acceleration performance than a conventional vehicle with the same size engine. An example of this design is the new Lexus RX400h.

Micro Hybrids

Finally, let’s discuss micro hybrids. These are conventional vehicles powered either by gasoline or diesel engines in which the 12-volt starter motor has been eliminated and a specially designed, belt-driven integrated starter/generator (ISG) has been installed in place of the conventional alternator. While the ISG of a micro hybrid cannot help to propel the vehicle, it can provide two important hybrid features. First of all, a micro hybrid will feature idle stop. Engine control circuitry is included in a micro hybrid which will shut down the internal combustion engine when the vehicle is at rest. This feature alone can improve fuel economy by 10% to 15% in city/urban driving environments. The electronic control system in a micro hybrid can also control the charge cycle of the alternator so that it produces electricity to recharge the vehicle battery primarily during

deceleration and braking. This provides a mild amount of regenerative braking and an additional gain in efficiency. The Citroen C3, currently being sold in Europe, is a micro hybrid vehicle. Belt driven Integrated Starter Generators will replace these components in Micro Hybrids Cost Comparison

Full, power and mild hybrid designs all carry a significant price premium (three to five thousand dollars) in order to obtain a 20% to 30% improvement in fuel economy. Micro hybrid technology will cost much less when it becomes available. It has been estimated that micro hybrids could cost only $300 to $400 more than conventional vehicles, yet this small additional investment could yield up to a 15% improvement in fuel economy! Micro hybrids, on the basis of cost versus benefit, are poised to become a significant part of the hybrid market!

Mild Hybrid Full Hybrid Power Hybrid Macro Hybrid electric launch or

drive at times

using only Electric

Motor

idle stop

regenerative

braking

Stop/Start function

when coasting,

Electric Boosting

(with a downsized

engines) with still

powerful

engines

IC Engine Downsized Downsized Conventional

Conventional Electric Motor Crank drive Crank drive /Powersplit Crank drive

/Powersplit

Belt/Crank Drive Electric Power 10-20kW 15-50kW = full Hybird

4-10kW Voltage >42V >100V = full Hybird

42V Main Battery NiMH/ Supercapacitor 25kg NiMH/Li Ion 40kg = full Hybird NiMH

25kg

Fuel Economy Improve. 15-25% 20%-30% = full Hybird 6-10%

Additive Cost 900-2200Euro 2500-5000Euro 500-900 Euro

Vehicle examples GMC Sierra

pickup, Honda

Civic/Accord The Ford Escape, Toyota Prius Lexus RX400h(V6 3.3L)

Citroen C3 With only Electric Motor, Ford Escape could have 40km/h speed.

Why lower Emission than conventional ICE (Internal Combustion Engine) vehicles?

Much fewer idle running than Conventional ICE vehicles.

Because of Electrical boost of Electric Motor, IC Engine need less frequently to working at full load (Gasoline Engine is of little measures to control its emissions)

Because of Electrical boost of Electric Motor, IC Engine would work at comparatively steady and narrow area. Thus fewer pollutant would be emitted.

Why Lower Fuel Consumptions?

Fewer or without idle running of IC engine

Stop IC Engine, while vehicle coasting, down-slop driving, and some other working condition no power need to be transmit to wheels.

Generative braking and electric generation when coasting, this could recovery kinetic energy into electric energy and then store it into battery packs.

With electric boosting, engine would be downsized, thus fewer fuel consumptions. In other way, with electric motor to drive vehicle, engine would running at comparative narrow range of better fuel economy and less emissions. The bigger Power of E-Motor and Battery pack, the narrower area engine would running at, independent of vehicle running. For instance, Santana 3000 2V2L, the most fuel economic area is 2000-4000 rpm. 60%-90% load.

?Challenges of Hybrid:

o Weight

o Cost

o Packaging/NVH of passenger vehicle applications

Calibration:

focuses on electric boost (Torque Arbitrary) and generation with an optimum state-of-charge, start/stop and gear selection.

regenerative braking requires sophisticated electronically controlled braking technology commonly known as brake by wire.

Calibration target:

driveability,

fuel economy,

emissions ,

NVH Optimization

Components:

Batteries

One of the key components of the electric hybrid system is the battery. Besides the mature lead acid technology for low power applications, the de facto standard for passenger cars in today's production applications is the NiMH technology. Since the lifetime of these batteries is closely related to the State of Charge (SOC) strategy, overall optimization is mandatory.

New emerging technologies, like Li-Ion, are expected to improve system capabilities within the next few years

PRIUS I /Toyota Batterie (274 V) Warranty — 8 years

PRIUS II /Toyota Batterie (500V max) Warranty – 10 years

Lexus RS400h Hybrid System (288V, could be boosted up to 650V by inverter when necessary) Warranty --- 8 years / 100,000 miles

Ford Escape Batterie (330V) Warranty – 8 years / 100,000 miles

PSD (Power - Split – Device) used for Series/Parallel:

Prius doesn’t actually have a transmission, because there are no gears and the power carriers are permanently engaged. The illustration you see above is a simplified diagram of what Prius has for the transfer of power instead. It very closely resembles another component found in all vehicles, a differential. The only difference is that there are multiple sources of power, rather than just one; hence the name “Power-Split-Device ”. To keep references simple, it can be called: “PSD ”.

Another reference for this device is a CVT (Continuously Variable Transmission), but it is not type found in both traditional vehicles and other types of hybrid, called: “Cone & Belt ”. Instead, this CVT is referred to as the “Planetary ” type, due to the orbital movement of the components within.

The entire PSD is remarkably small, only the size of an adult hand’s palm. Each of the carriers has the ability to rotate in its own unique way, providing a wide range of power options. The “Ring ” carrier is sometimes powered by the battery-pack to provide the ability to drive using only electricity (both forward & backward), allowing the engine to stop running to save gas. At other times, the “Ring ” carrier creates power, regenerating electricity when you use the brakes. The “Planet ” carrier is powered by the engine, which causes rotation of both the car’s wheels (for driving forward) and the “Sun ” carrier (for generating electricity). And while the “Planet ” & “Sun ” carriers are spinning, the “Ring ” carrier can join in to provide additional thrust to the wheels or to allow engine RPM to be reduced. Lastly, the “Sun ” carrier is also used for starting

the engine.

“SUN ” carrier

10 kW Electric Motor/Generator

“RING ” carrier

50 kW Electric Motor/Generator

“PLANET ” carrier

1.5 liter Gasoline Engine (57 kW)

This is a clever gearbox that hooks the gasoline engine, generator and electric motor together. It allows the car to operate like a parallel hybrid -- the electric motor can power the car by itself, the gas engine can power the car by itself or they can power the car together.

RX 400h Hybrid Technology

1. 3.3 L 24-V DOHC V-6 Engine with VVT-i – The primary power source for your vehicle, the engine works in conjunction with the hybrid battery to deliver power to the ECVT.

2. Electric Motor / Generator (MG1 ) – Serves as the starter motor for the engine and a “pathway” for the engine’s power to reach the front wheels.

3. Front Electric Motor / Generator (MG2) – Delivers power to the front wheels. It can run alone or with the engine. It is driven by electrical power from MG1 and/or the hybrid battery. During braking or deceleration, it generates electricity to recharge the hybrid battery.

4. Rear Electric Motor* / Generator (MGR)* – Operates when starting from a stop, during hard acceleration, sharp turning, and if the front wheels slip. It is driven by electrical power from the hybrid battery and MG1 as needed. During braking or deceleration, it generates electricity to recharge the hybrid battery. The All-Wheel Driveu system operates automatically as needed.

5. Hybrid Battery – Composed of sealed nickel-metal hydride modules, the 288-volt hybrid battery is located under the rear seat. It supplies power to the electric motors during start-up, acceleration, uphill driving, and reverse. It supplies power to the Inverter for use by the electric motors and stores regenerative energy captured during coasting and braking conditions.

6. Inverter – Converts the hybrid battery’s high voltage DC current into AC current for the electric motors and vice versa, depending on driving demands and electrical system needs. Taking the function of a conventional alternator, it maintains the 12-volt battery. The inverter can also boost the hybrid battery’s power up to 650 volts as needed.

7. Hybrid Electronic Control System – Monitors and controls the power flow operation of MG1, MG2, MGR*, and the inverter.

8. Regenerative Braking System – Helps recover energy used to slow the vehicle during braking or coasting. During braking or coasting, MG2 and MGR* turn into generators, which create electricity to help charge the hybrid battery. As they create electricity, they create drag, which helps slow the vehicle. The conventional brake system and the regenerative brake system work in conjunction with each other.

9. Electronically-controlled Continuously Variable Transmission (ECVT) – Delivers smooth acceleration without conventional gear shifting, while enhancing efficiency. It has fewer parts than a conventional automatic transmission. MG1 and MG2 are part of the ECVT. During sustained highway cruising, the ECVT helps maximize fuel economy for the engine.

10. 12-volt Battery – Enables the Hybrid Electronic Control System to "start" the hybrid system (vehicle “READY” mode) and operates the basic electrical system. This battery is charged by the inverter.

* Vehicles with optional All-Wheel Drive only.

Typically, the system works as follows:

Starting from a stop

The front electric motor/generator (MG2) and the rear electric motor/generator (MGR*) both drive the vehicle. The engine is not required to start moving the vehicle, but may come on to charge the hybrid battery or make heat available for the climate control and emissions systems.

Normal acceleration

MG2 and the engine drive the vehicle. MGR* is not powered. The engine drives MG1 as a generator to power MG2 and charge the hybrid battery as needed.

Full acceleration

The engine, MG2, and MGR* work together to drive the vehicle. The hybrid battery supplies additional power to MG2 and MGR.

Cruising (constant speed)

Primarily, the engine will drive the vehicle. The engine, MG1, MG2, and MGR* will come on as needed depending on road conditions and other factors. MG2 and MGR* may act as motors or as generators depending on the need to make power or regenerate electricity to recharge the hybrid battery.

Coasting and braking

As part of the regenerative braking system, MG2 and MGR* act as generators to regenerate electricity to charge the hybrid battery. The engine may turn off before the vehicle comes to a complete stop.

Backing-up

MG2 and MGR* reverse direction to drive the vehicle. The engine is typically off, unless it is needed to recharge the hybrid battery or warm-up the engine.

* Vehicles with optional All-Wheel Drive only.

Performance of Lexus RX400h AWD

EPA Tests Assume:

? Very slow acceleration

? Straight, level roads

? Air-conditioning is turned off

? 18% idle time for city test

? 0 idle time for highway test

? Average speed of 20 mph for city test

(top speed 56 mph)

? Average speed of 48 mph for highway

test (top speed of 60 mph)

Existing and New Hybrid Vehichles

Hybrid Vehicle Timeline

Hybrid passenger vehicle events and models from their origins to

new hybrids in the pipeline

1997 | 1999 | 2000 | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008-2009

Concept Hybrids | "Hollow Hybrids"

1997

1997 Toyota Prius

Toyota launches world’s first mass-production hybrid vehicle, in Japan

37,000 sold in Japan before U.S. introduction in 2000.

1999

2000 Honda Insight

Honda releases first hybrid vehicle available in the United States. Ends production in September 2006.

EPA Estimated MPG: 65 (manual) 56 (auto)

EPA Smog Score (10 best): 2 (manual) 6 (auto)

Recommended reviews of the Insight can be found here . 2000

Toyota Prius

After selling 37,000 units in Japan, Toyota launches Prius in U.S. EPA Estimated MPG: 48

EPA Smog Score (10 best): 3

Recommended reviews of the Prius can be found here . 2001

U.S. hybrid car sales reach 20,000 annually. 2002

2003 Honda Civic Hybrid (5 seat compact)

EPA Estimated Combined MPG: 47-48 EPA Smog Score (10 best): 9 (CA-emissions), 3 (lean-burn)

Used lean-burn engine technology for models outside of

California—boosted mpg but also increased in smog-forming emissions.

Recommended reviews of the Civic can be found here . Total U.S. hybrid sales pass 100,000

2003

2004 Toyota Prius (5 seat midsize)

EPA Estimated Combined MPG: 55 EPA Smog Score (10 best): 8

The first hybrid midsize car, the second generation Prius was named

2004 Car of the Year by Motor Trend

Recommended reviews of the Prius can be found here . 2004

2005 Ford Escape Hybrid (5 seat compact SUV)

EPA Estimated Combined MPG: 31-33 EPA Smog Score (10 best): 7

First hybrid SUV & first American-made hybrid. Named North American

truck of the year in 2005.

Recommended reviews of the Escape can be found here .

2005 Honda Accord Hybrid (5 seat sedan)

EPA Estimated Combined MPG: 32 EPA Smog Score (10 best): 6

While not a full-fledged “muscle hybrid” the Accord sedan is the first

mainstream use of hybrid technology to boost performance more than fuel

economy. 2006 accord gets less fuel economy (25 mpg city/34 mpg highway).

Honda reports in 4/06 that it may cut production due to sluggish sales. Recommended reviews of the Accord can be found here.

GM attempts to greenwash hybrid market with its first "hollow hybrids ."

2005

Total U.S. hybrid sales in 2005: 205,749

2006 Lexus RX 400h (5 seat midsize SUV)

Toyota brings hybrid technology to the luxury and midsize SUV segments.

EPA Estimated Combined MPG: 29-30

EPA Smog Score (10 best): 8

Toyota brings hybrid technology to luxury SUV market, but is it a

“muscle hybrid?”

Recommended reviews of the RX 400h can be found here . 2006 Toyota Highlander (7 seat midsize SUV)

EPA Estimated Combined MPG: 29-30 EPA Smog Score (10 best): 8

Questions as to how much fuel economy the Highlander Hybrid gives

up for greater power.

Recommended reviews of the Highlander can be found here . 2006 Mercury Mariner (5 seat compact SUV)

EPA Estimated Combined MPG: 31 EPA Smog Score (10 best): 7

Ford’s “Tricked Out” version of the Escape Hybrid gets limited 2,000

production in ‘05.

Recommended reviews of the Mariner can be found here . 2006 Civic Hybrid (5 seat compact)

EPA Estimated Combined MPG: 50 EPA Smog Score (10 best): 9

Significantly redesigned in 2006, the new Civic Hybrid boosts mileage

and reduces emissions while providing more “pep.”

Recommended reviews of the Civic can be found here .